Anti-explosion light source assembly of LED lamp

A technology of LED lamps and light source components, which is applied in the direction of light source, light source fixing, lighting device components, etc. It can solve the problems of loose heat sink and lampshade, affecting the sealing explosion-proof performance, and low sealing effect, so as to improve the sealing performance and improve the sealing effect. The effect of connection strength and large sealing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

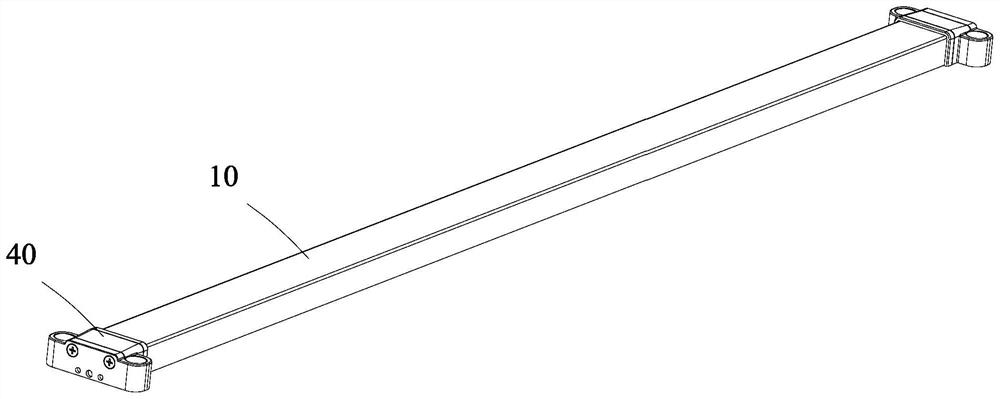

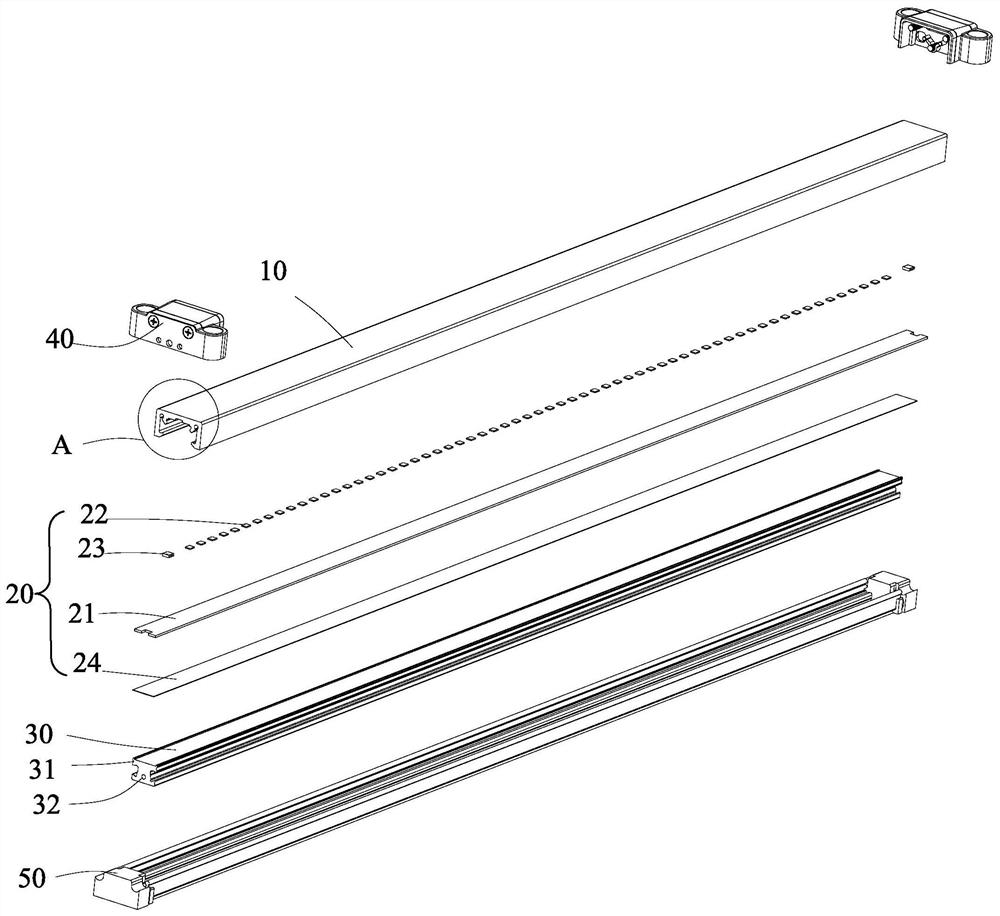

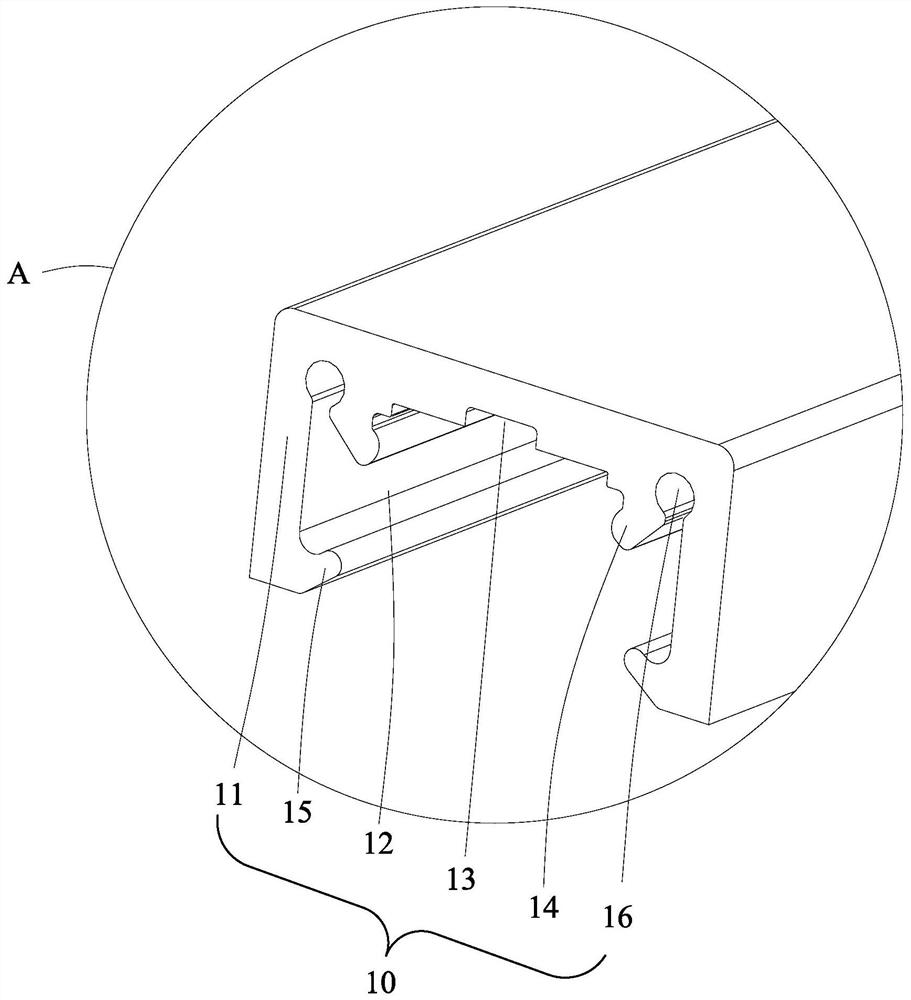

[0022] Such as Figure 1 to Figure 7 As shown, it is a structural schematic diagram of the explosion-proof light source assembly of the LED lamp provided by the present invention. The explosion-proof light source assembly of the LED lamp includes a light bar cover 10, a light source assembly 20 arranged in the light bar cover 10, a heat sink 30 arranged on the light source assembly 20, and two heat sinks respectively arranged on the light bar cover 10. The end caps 40 at both ends of the light bar cover 10 , and a casting part 50 molded in the light bar cover 10 . It is conceivable that the explosion-proof light source assembly of the LED lamp also includes some other functional modules, such as connection assemblie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com