Enhanced vapor injection bypass structure of scroll compressor

A technology of scroll compressors and gas injection to increase enthalpy, applied in the field of scroll compressors, can solve problems such as difficult system matching, large fluctuations in exhaust temperature, and poor heating capacity at low temperatures, so as to reduce fluctuations in exhaust temperature and improve The effect of heating capacity and good cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

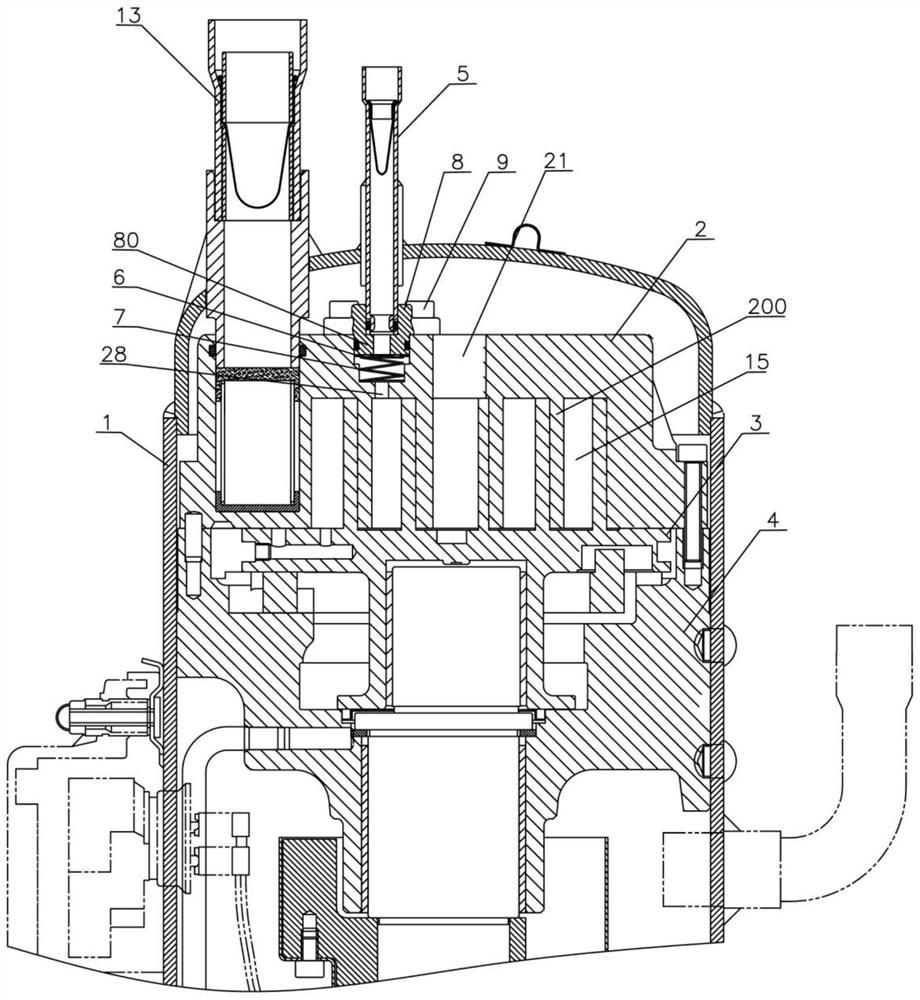

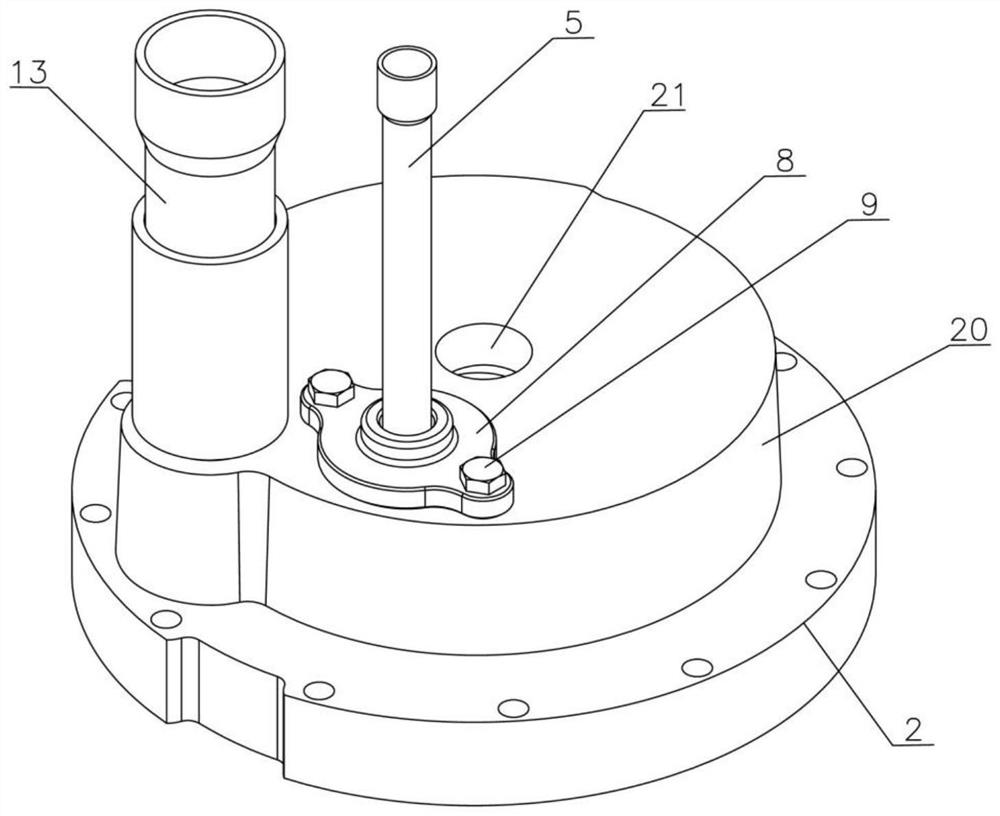

[0027] refer to Figure 1 to Figure 6 , an air injection enthalpy-increasing bypass structure of a scroll compressor, the scroll compressor includes a casing 1 and a fixed scroll 2 , a moving scroll 3 and a frame 4 installed in the casing 1 .

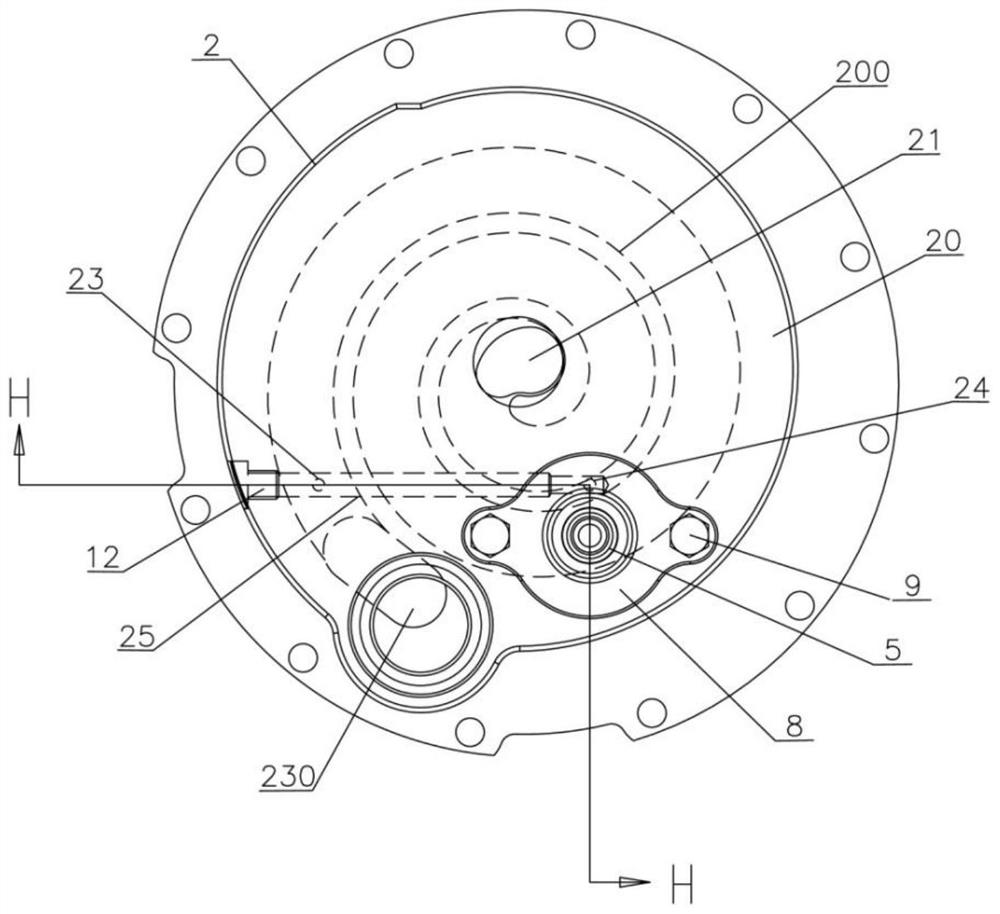

[0028] specific reference Figure 6 , the fixed scroll 2 has an end plate 20 and a spiral tooth 200 arranged on the end plate 20, the spiral tooth 200 spirally coils to form a scroll chamber 22, and the edge of the end plate 20 has a The tail end of 22 communicates with the air inlet 230, and the middle part has an exhaust port 21 communicated with the center of the vortex chamber 22. The end plate 20 is provided with a mounting counterbore 26 and an air injection enthalpy increasing hole 28 connected in sequence from the back to the inside. The air injection enthalpy-increasing hole 28 communicates with the middle section of the scroll chamber 22 , and the inner diameter of the installation counterbore 26 of the fixed scroll 2 close t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com