Method for integrating in-situ pyrolysis of oil-rich coal and geological storage of CO2

A technology of geological storage and in-situ pyrolysis, which is applied in the development of fluids, petroleum industry, earth-moving drilling, etc., can solve the problems of instability and leakage of geological bodies, and achieve the goal of increasing supply channels, increasing contact area, and improving recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

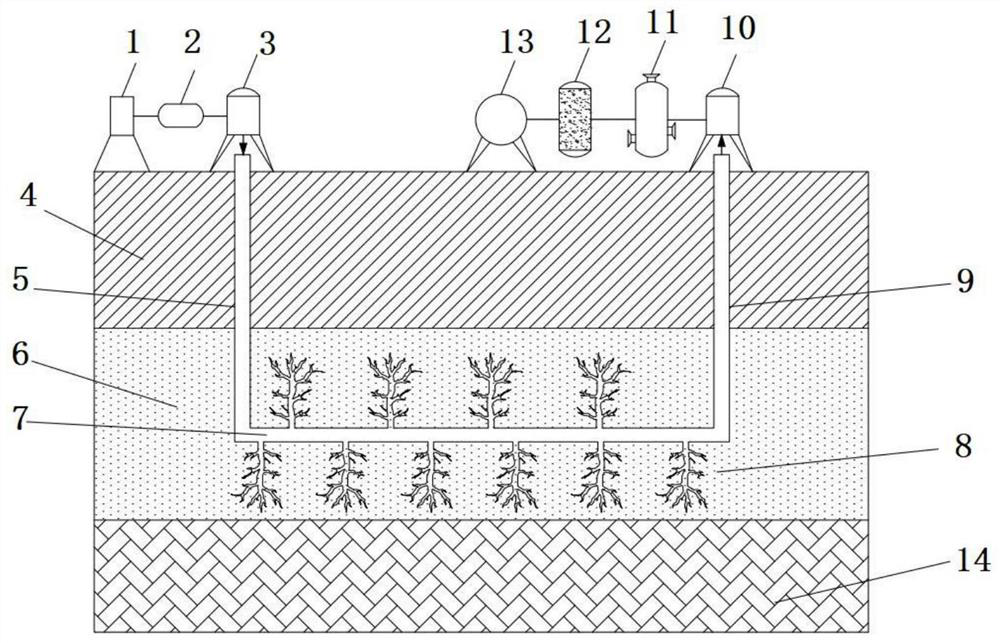

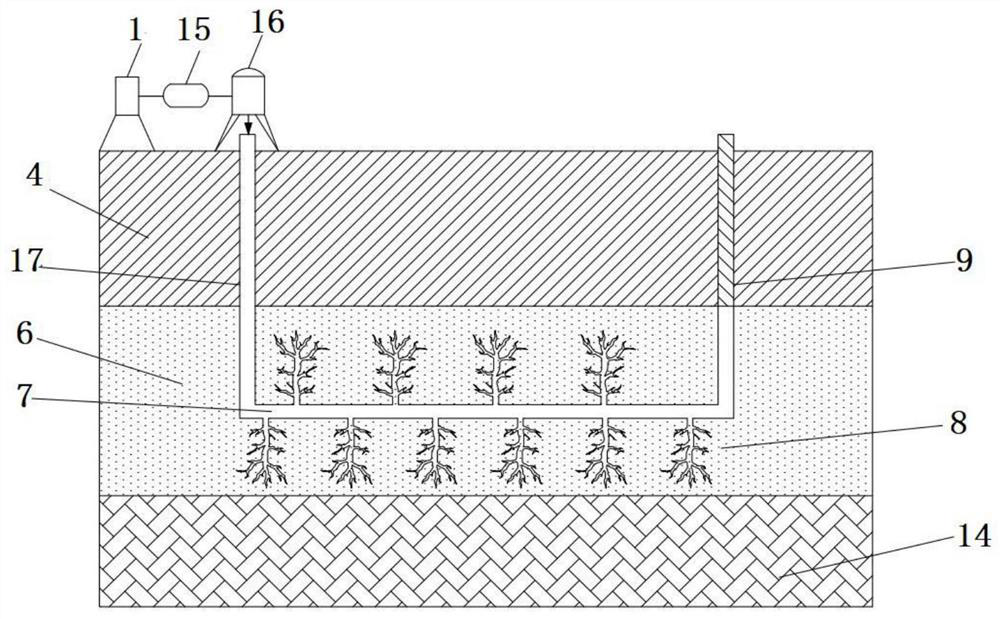

[0036] Such as figure 1 and figure 2 As shown, this embodiment includes the following steps:

[0037] Step 1, drilling along the coal seam roof 4 to the direction of the coal seam 6, respectively forming the injection well 5, the extraction well 9 and the horizontal well 7, and the injection well 5 and the extraction well 9 are connected through the horizontal well 7; the injection well 5 and the extraction well 9 both penetrate the coal seam roof 4 and enter the coal seam 6, and the horizontal well 7 is located in the coal seam 6 above the coal seam floor 14;

[0038] Step 2: Drill the coal seam surface of the horizontal well 7 formed in step 1 to form a borehole, and then use the energy supply in the energy harvesting device 1 to inject the fracturing fluid into the horizontal well 7 through the injection well 5 through the pressurizing device 2 And enter the borehole to pressurize, so that the coal seam at the drillhole position is cracked to form a fracture 8, and then ...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that the pyrolysis thermodynamic system in step 2 includes a heating rod arranged in the borehole of the horizontal well 7; the process of said heating and pyrolysis is: start the heating rod to The coal seam in Hirai 7 is heated and pyrolyzed to obtain pyrolysis solid products and pyrolysis gas products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com