Advanced premixing abrasive water jet equipment and generation method

An abrasive water jet and pre-mixing technology, applied in the field of abrasive water jet, can solve the problems of insufficient acceleration, long abrasive acceleration time, short abrasive acceleration time, etc., and achieve the effects of simple device, long acceleration time, and short acceleration time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

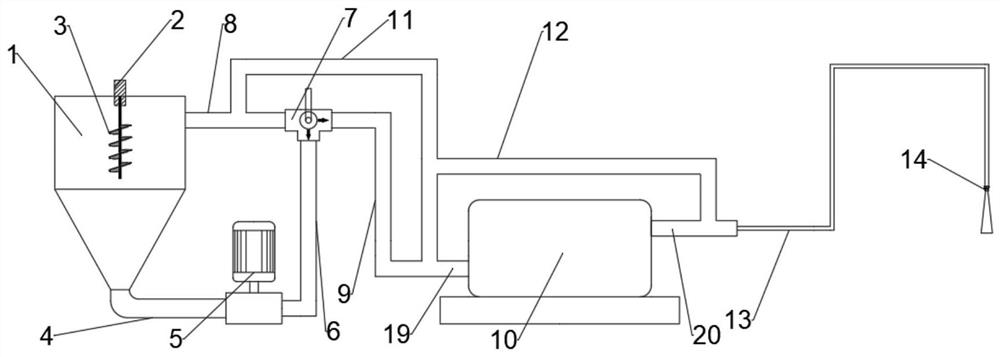

[0047] see Figure 1~5 , the present invention provides an advanced pre-mixed abrasive water jet equipment, including: mixing tank 1, agitator 3, feeding pump 5, grouting pump 10 and nozzle 14;

[0048] Wherein, the stirring tank 1 is provided with a stirrer 3 capable of circulating stirring inside;

[0049] The bottom of the mixing tank 1 is communicated with the input end of the feed pump 5 using a pipeline-4;

[0050] The output end of the feed pump 5 is communicated with the liquid inlet end of the three-way ball valve 7 using a pipeline two 6;

[0051] One of the liquid outlets of the three-way ball valve 7 is connected to the mixing tank 1 through the pipeline three 8, and the other liquid outlet is connected to the grouting pump inlet 19 of the grouting pump 10 through the pipeline four 9 ;

[0052] The grouting pump outlet of described grouting pump 10 adopts high-pressure hose 13 to be connected with nozzle 14, by arranging high-pressure hose 13, it is convenient to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com