Non-woven fabric wet tissue

A technology of non-woven fabrics and wet wipes, applied in applications, cleaning equipment, household appliances, etc., can solve the problem that wet wipes cannot be separated from wet and dry, and achieve the effects of novel structure, convenient use, and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

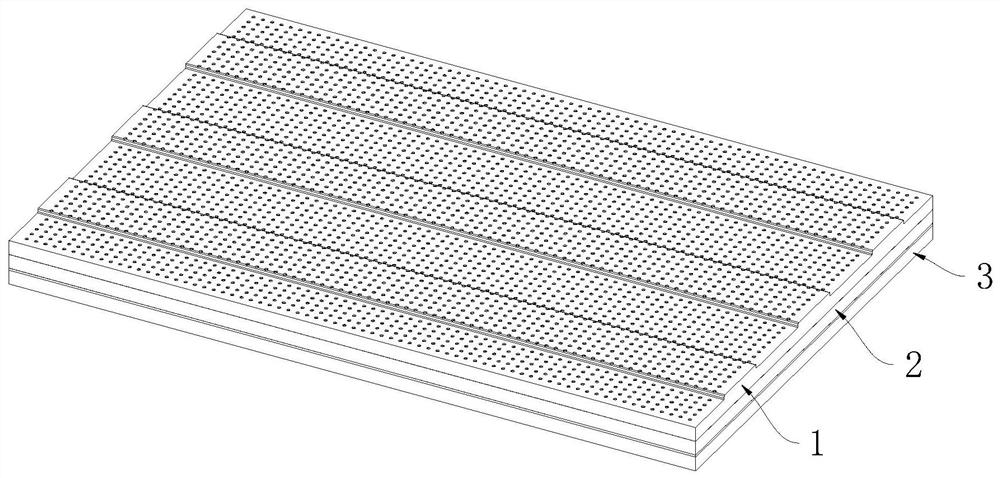

[0033] As an embodiment of the present invention, the water storage layer 2 includes a sponge layer 21 fixedly connected to the lower surface of the wet surface layer 1, and the upper surface of the sponge layer 21 is provided with multiple sets of "convex" grooves. The interior of the "convex" groove of the sponge layer 21 is fixedly equipped with explosive beads 22;

[0034]During the production process, the pop-up beads 22 are arranged in an array at the lower end of the vacuum suction cup for extrusion, and are stably installed inside the "convex" groove of the sponge layer 21. The "shaped groove structure can reasonably limit the explosive beads 22 to prevent the explosive beads 22 from moving or detaching from the sponge layer 21. The material of the sponge layer 21 can buffer and protect the explosive beads 22 during transportation and vibration to avoid explosion. Bead 22 ruptures, thereby greatly improved the stability of bursting bead 22.

[0035] As an embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com