Safety monitoring system and method for thermal power plant in mixed coal combustion mode

A technology for safety monitoring systems and thermal power plants, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as slagging and overheating of superheaters, boiler combustion safety issues, and decreased operating stability , to achieve the effect of reducing the database capacity, reducing the monitoring workload and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

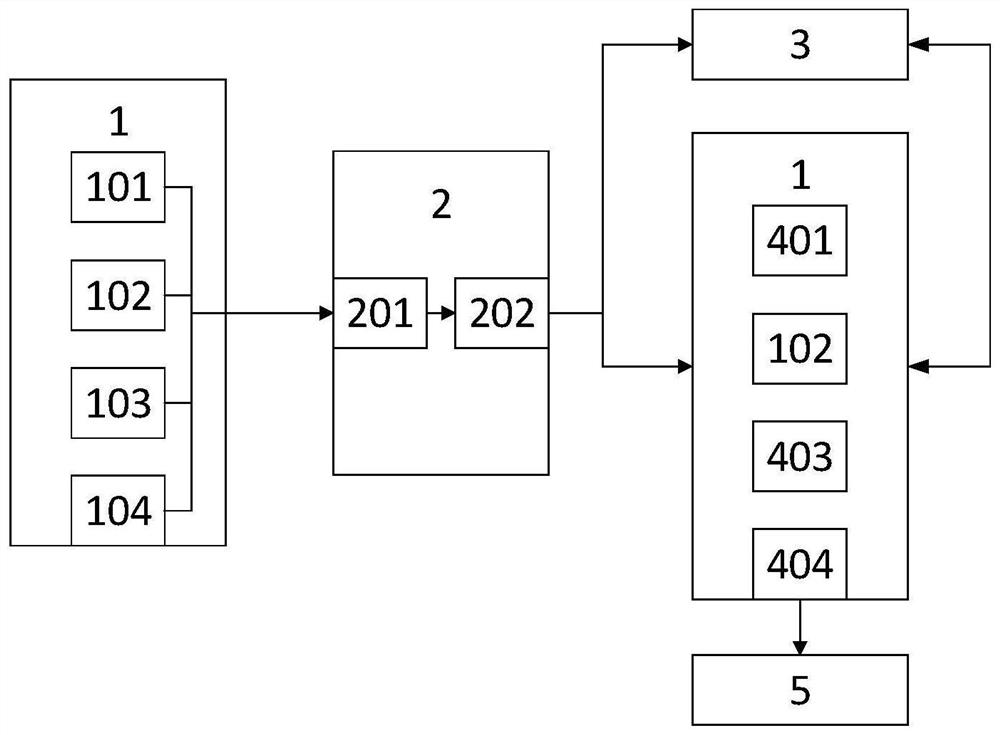

[0048] like figure 1 As shown, a thermal power plant safety monitoring system under the mixed coal combustion mode includes a data acquisition subsystem 1 and a data processing subsystem 2 connected in sequence, and the data processing subsystem 2 is connected with the data storage subsystem 3 and the safety analysis subsystem respectively. 4 phases are connected, and the safety analysis subsystem 4 is respectively connected with the data storage subsystem 3 and the alarm triggering subsystem 5, wherein the data acquisition subsystem 1 is used for real-time acquisition of boiler operating data, and the data acquisition subsystem 1 includes:

[0049] The boiler wall temperature parameter collection module 101 is used to collect the temperature data of each heating surface of the boiler;

[0050] Boiler host equipment parameter acquisition module 102, used to collect boiler host data from the DCS system of the power plant;

[0051] Boiler auxiliary equipment parameter acquisiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com