Structural design method of high-strength retainer for ball cage type constant velocity universal joint

A constant velocity universal joint, structural design technology, applied in mechanical equipment, elastic coupling, coupling and other directions, can solve the problems of short life, high use cost, bearing wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: A structural design method of a high-strength cage for a cage-type constant velocity universal joint, which is carried out according to the following design method:

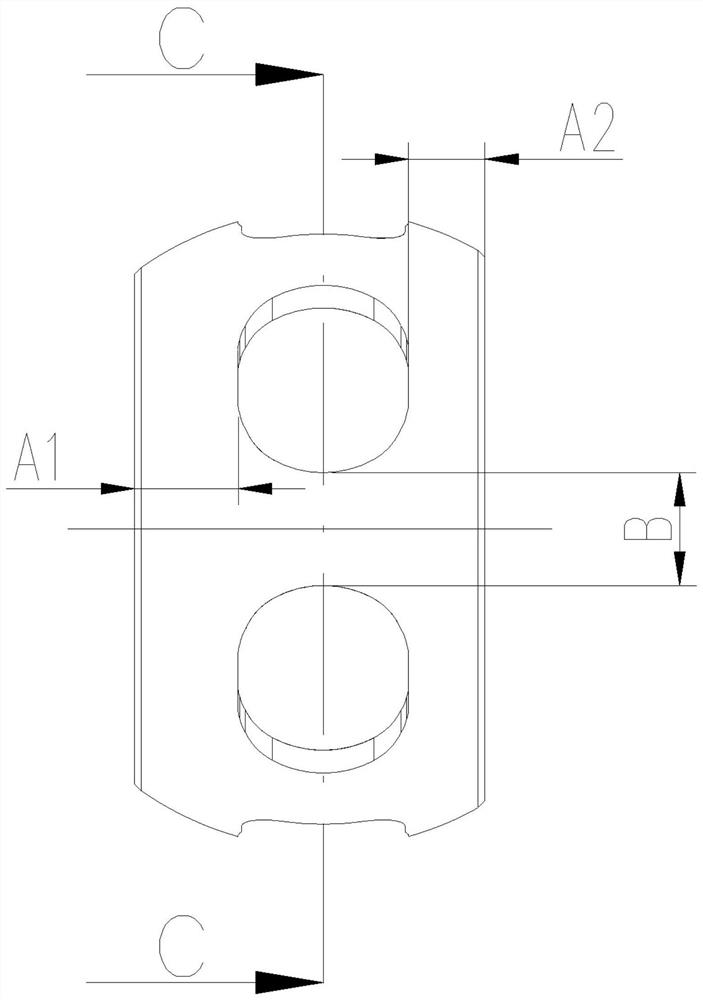

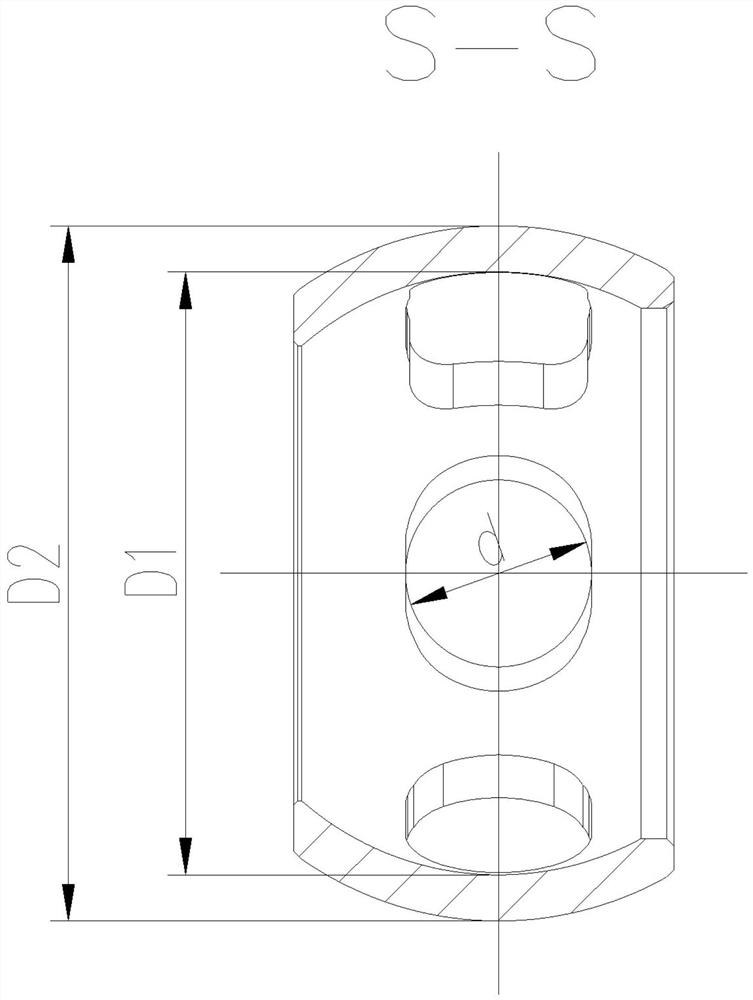

[0035] ①. Increase the width of the cage, that is, increase the dimensions A1 and A2:

[0036] Increase the size of A1, and A2 can ensure that the inner star wheel can be installed, that is, A1≠A2, and the dimensions of A1 and A2 are designed as follows:

[0037] A1=0.6~0.68*d

[0038] A2=0.5~0.55*d;

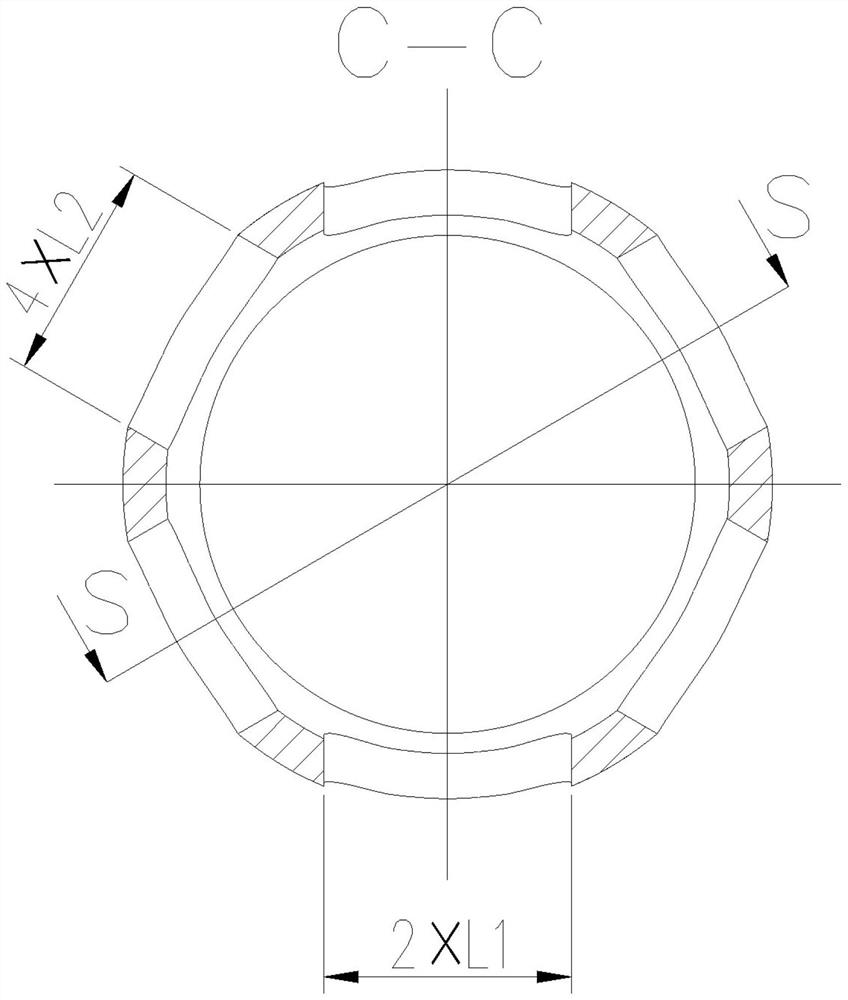

[0039] ②. Increase the width B of the window beam, and design four small and two large window holes, that is, reduce the dimensions L1 and L2:

[0040] L1 is enough to ensure that the inner star wheel can be installed, and L2 is enough to ensure that the steel balls have a rolling gap in the fairway. The dimensions of L1 and L2 are designed as follows:

[0041] L1=1.39~1.41*d

[0042] L2=1.26~1.27*d;

[0043] Around the L1 window hole, try to design a large round corner transition, the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com