Salt inhibitor, and method for deacidifying incineration flue gas by using same

A salt-resistance and deacidification technology, which is applied in the field of saline wastewater treatment in the incineration system, can solve problems that affect the stable production of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

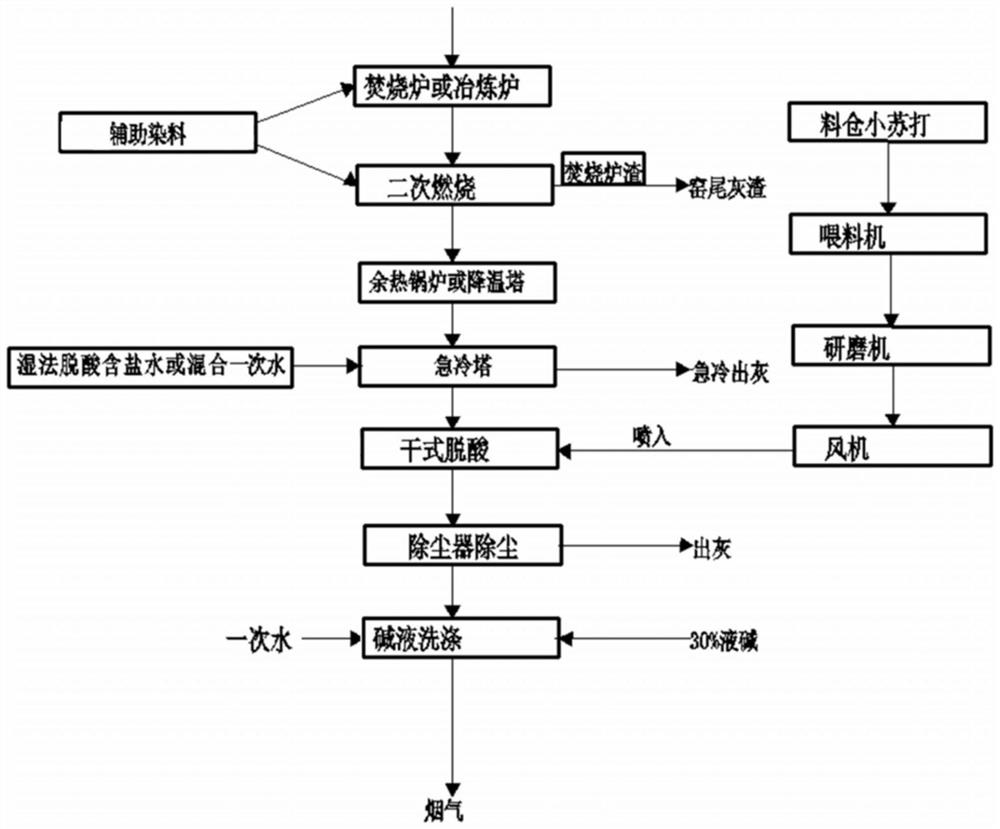

[0047] A method for deacidifying incineration flue gas and realizing zero discharge of sewage, comprising the steps of:

[0048] After the high-temperature flue gas enters the quenching tower, the temperature suddenly drops below 200°C under the action of water or brine. Discharge after the dust collector.

[0049] Described incineration flue gas comprises the steps:

[0050] 1) When the high-temperature flue gas has no waste heat boiler, the cooling tower is used to cool the flue gas to above 500°C;

[0051] 2) The flue gas is rapidly cooled to below 200°C;

[0052] 3) The air grinder grinds the baking soda;

[0053] 4) Baking soda dry deacidification;

[0054] 5) Activated carbon adsorption;

[0055] 6) Filter dust removal;

[0056] 7) Step 4)-Step 6) are combined into one stage or used repeatedly to form multistage dry deacidification.

[0057] The rapid cooling of the flue gas in the step 2) adopts a downstream spray tower, and the high-temperature flue gas enters fro...

Embodiment 2

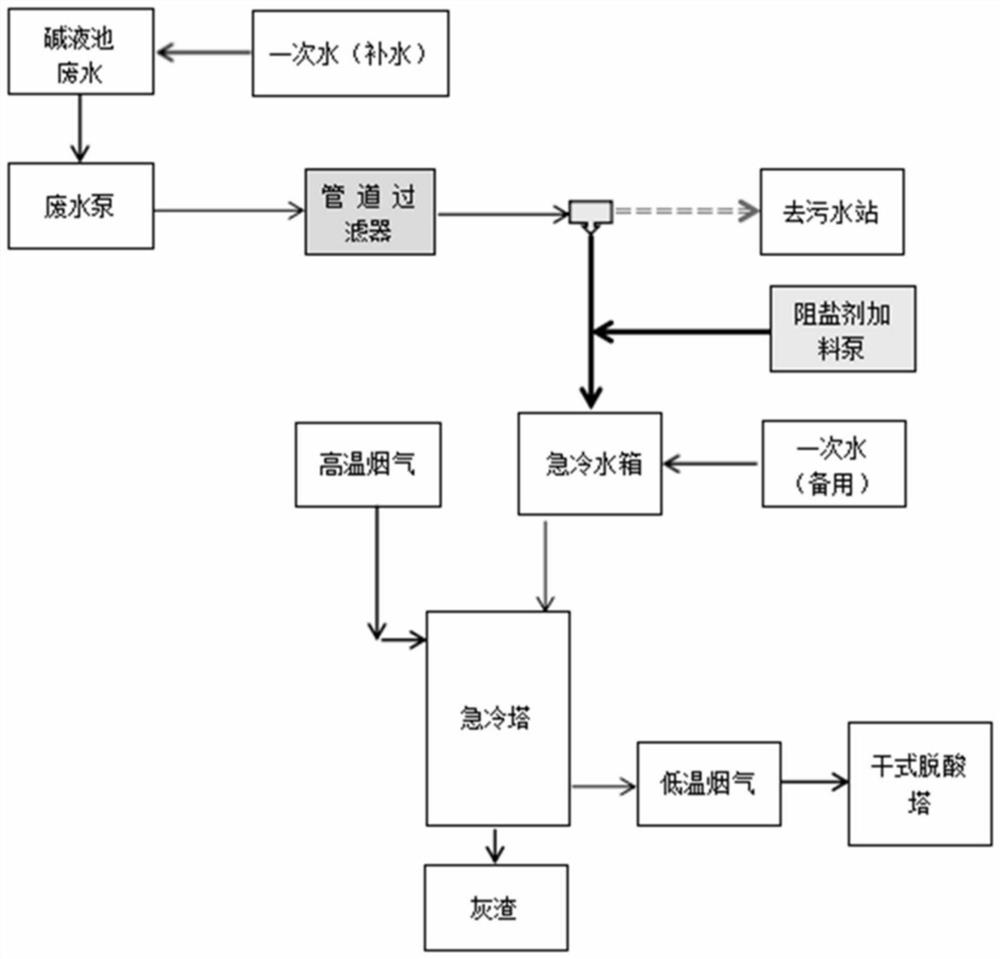

[0059] A method for deacidifying incineration flue gas and realizing zero discharge of sewage, comprising the steps of:

[0060] After the high-temperature flue gas enters the quench tower, the temperature suddenly drops below 200°C under the action of water or salt water. At this time, the ground sodium bicarbonate is sprayed in time for deacidification. When the high-salt wastewater is produced by deacidification method, and it is difficult to discharge the high-salt wastewater into the sewage treatment plant and the environment, a salt inhibitor is added to the high-salt wastewater, and after mixing evenly, the uniformly mixed high-salt wastewater is sprayed back into the Quenching tower.

[0061] Described incineration flue gas comprises the steps:

[0062] 1) When the high-temperature flue gas has no waste heat boiler, the cooling tower is used to cool the flue gas to above 500°C;

[0063] 2) The flue gas is rapidly cooled to below 200°C;

[0064] 3) The air grinder gr...

Embodiment 3

[0081] A method for deacidifying incineration flue gas and realizing zero discharge of sewage, comprising the steps of:

[0082] After the high-temperature flue gas enters the quenching tower, the temperature suddenly drops below 200°C under the action of water or salt water, and when the high-salt wastewater is difficult to discharge into the sewage treatment plant and the environment, a salt inhibitor is added to the high-salt wastewater and mixed After uniformity, the homogeneously mixed high-salt wastewater is sprayed back into the quenching tower, and at this time, the ground sodium bicarbonate is sprayed in time for deacidification.

[0083] Described incineration flue gas comprises the steps:

[0084] 1) When the high-temperature flue gas has no waste heat boiler, the cooling tower is used to cool the flue gas to above 500°C;

[0085] 2) The flue gas is rapidly cooled to below 200°C;

[0086] 3) The air grinder grinds the baking soda;

[0087] 4) Baking soda dry deac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com