Multi-channel single-head unwinding equipment

A technology of unwinding equipment and unwinding racks, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of affecting efficiency, poor use effect, etc., to ensure stability, flexible adjustment and precision, The effect of improving unwinding efficiency and space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

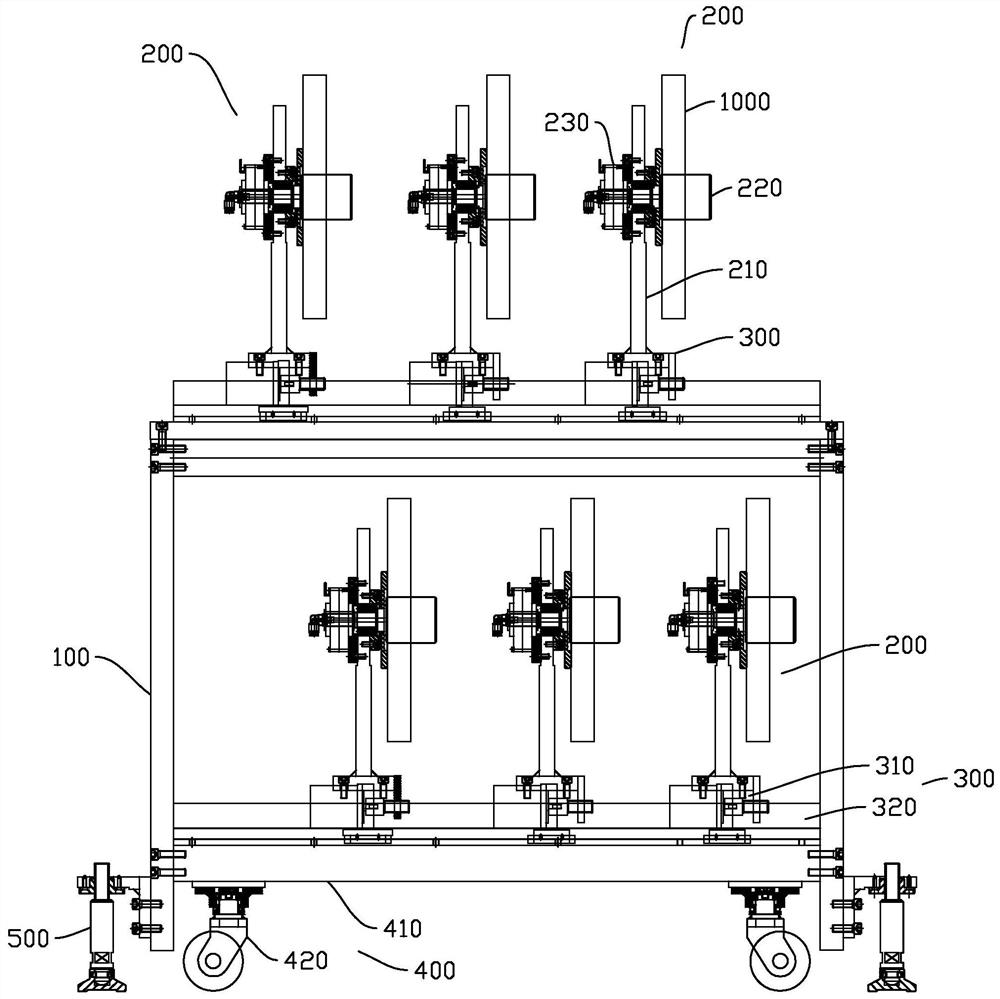

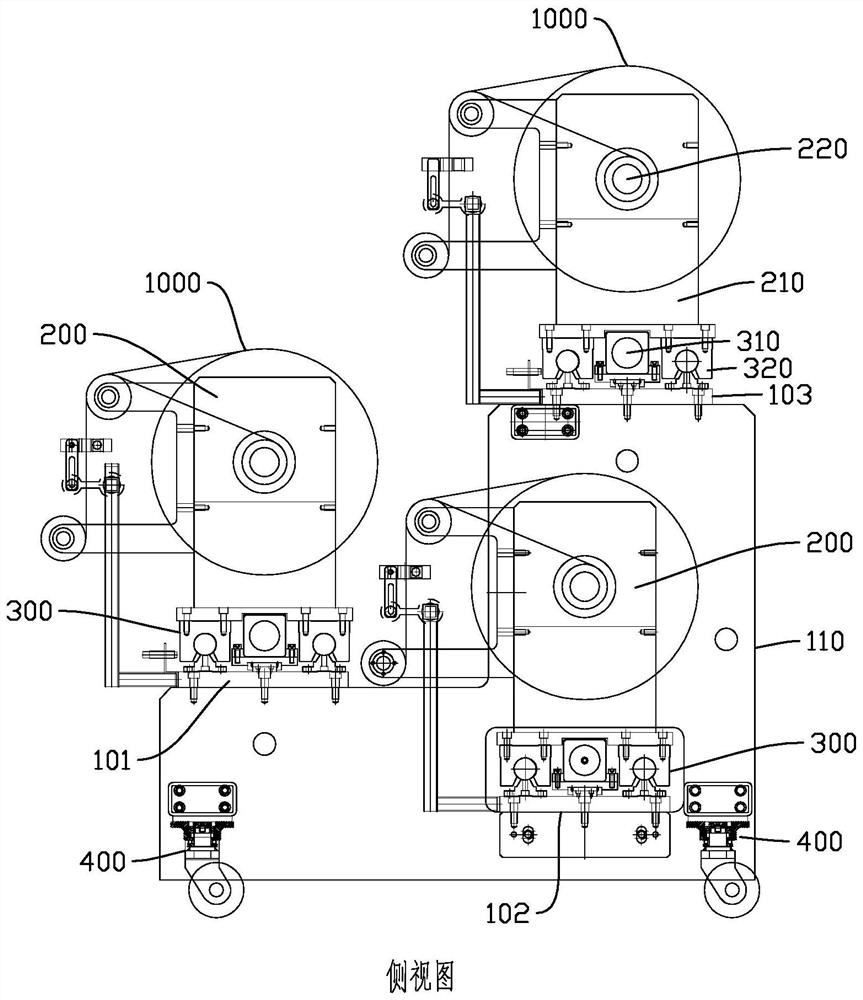

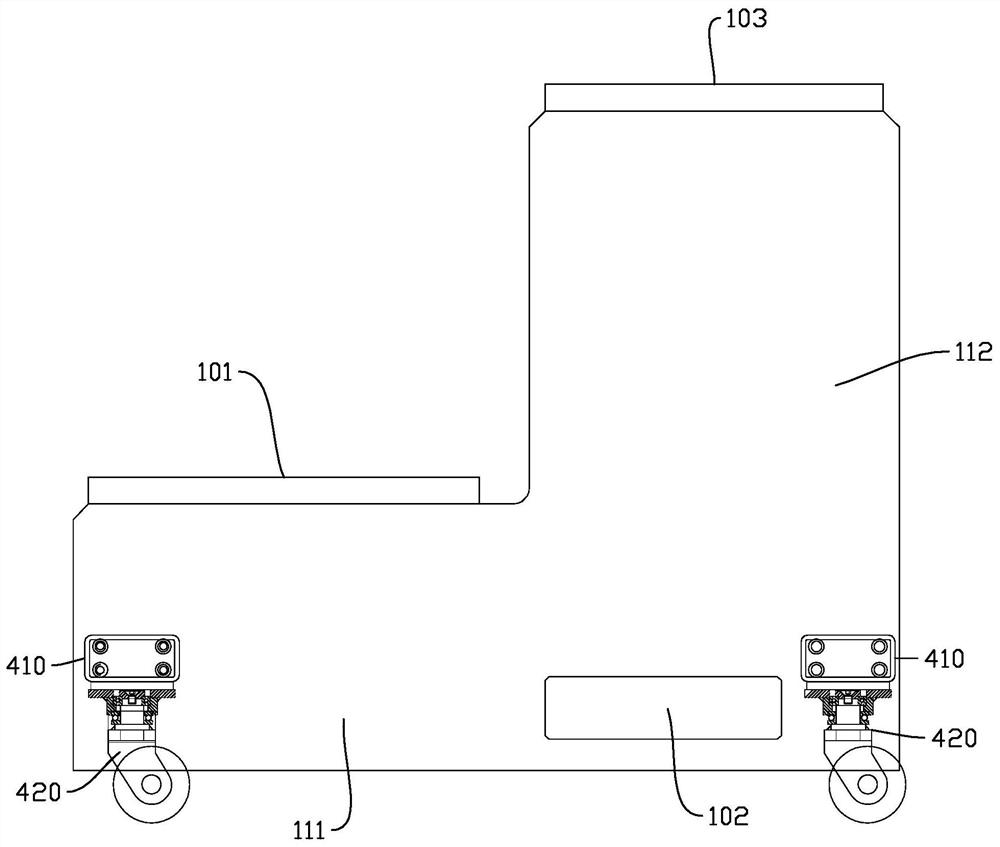

[0026] Such as Figure 1-2 In the structure shown, this multi-channel single-head unwinding equipment mainly includes a frame 100, an unwinding assembly 200 and a deviation correction assembly 300. The unwinding assembly is arranged on the frame to unwind the corresponding aluminum coils. And the deviation correction operation is performed on a single unwinding component through the deviation correcting component to ensure the stability of the unwinding process.

[0027] Specifically, the deviation correction assembly 300 includes a deviation correction driver 310 and a linear slide rail 320, the linear slide rail 320 is arranged on a placement frame, each of the deviation correction drivers 310 is connected to a single unwinding frame 210, and the deviation correction driver 310 Drive the connected unwinding rack 210 to move linearly along the linear slide rail 320, and the braking mechanism 230 includes a magnetic powder brake. The braking mechanism 230 is used to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com