Vehicle front lower protection cross beam, assembly and vehicle

A technology for vehicles and beams, applied in vehicle components, vehicle safety arrangements, bumpers, etc., can solve the problems of not being able to exert the strength of the protective beam body material, discounting the lightweight effect, and increasing the lower protective weight, so as to achieve local strengthening and lightweighting. Advantages, the effect of overcoming the complex protective structure, good promotion prospects and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The vehicle front lower protective crossbeam, assembly and vehicle described in the present invention will be further explained and illustrated in conjunction with specific embodiments and accompanying drawings. However, the explanations and illustrations do not constitute improper limitations on the technical solution of the present invention.

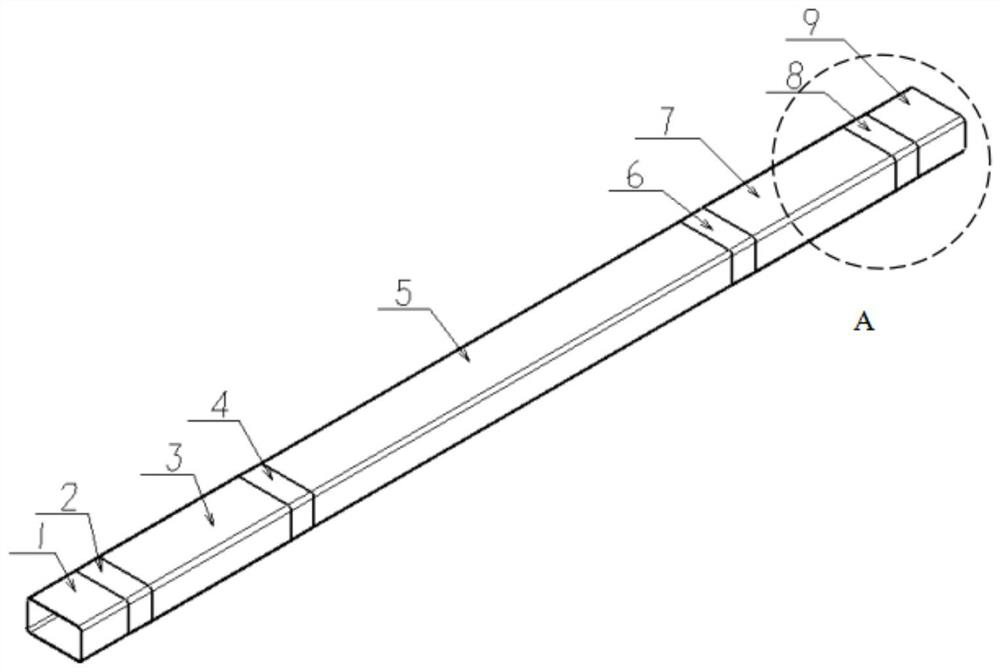

[0040] figure 1 It is a structural schematic diagram of an embodiment of the vehicle front lower protective beam according to the present invention.

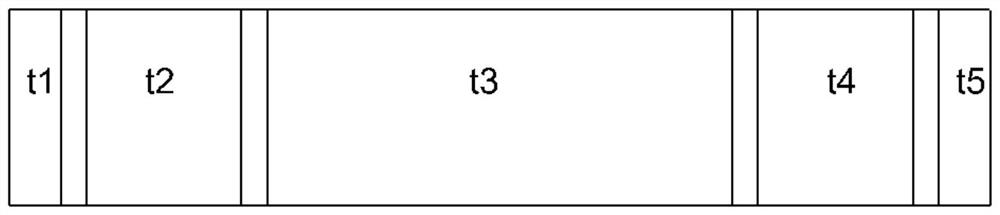

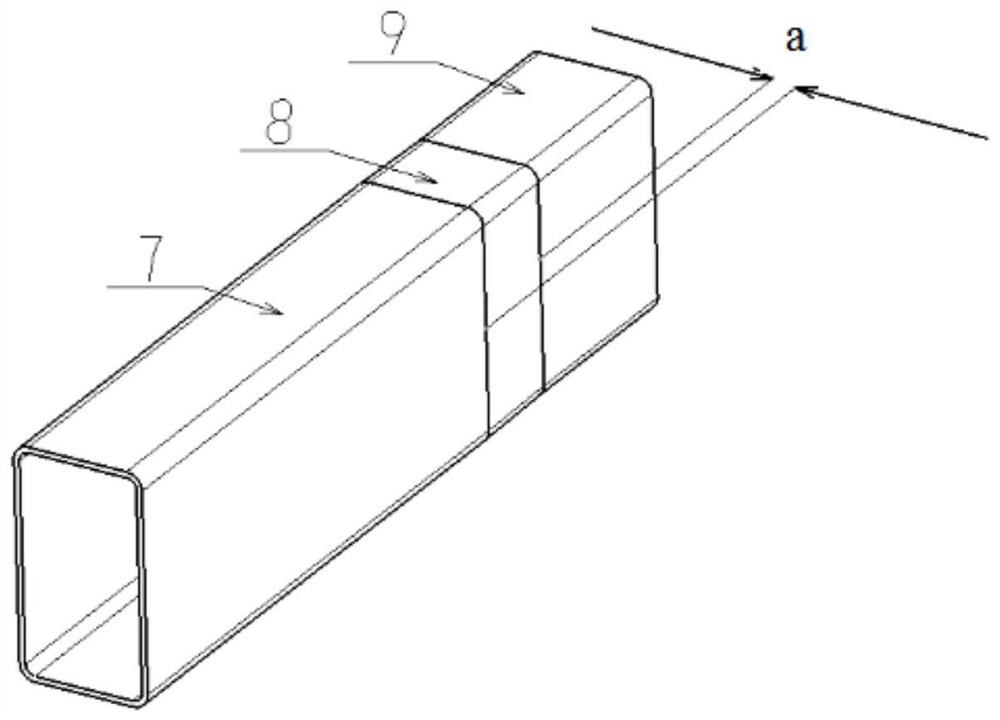

[0041] Such as figure 1As shown, in this embodiment, the vehicle front lower protective beam includes: middle section 5, reinforced transition section 4 and reinforced transition section 6, reinforced section 3 and reinforced section 7, distal transition section 2 and distal transition section 8 , distal segment 1 and distal segment 9. Wherein, the middle section is located in the middle of the longitudinal direction of the front lower protective beam of the vehicle, and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com