Wooden door processing system utilizing waste materials

A processing system and wooden door technology, applied in wood processing equipment, manufacturing tools, multi-purpose machinery, etc., can solve the problems of wasting forest resources and unusable leftover materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

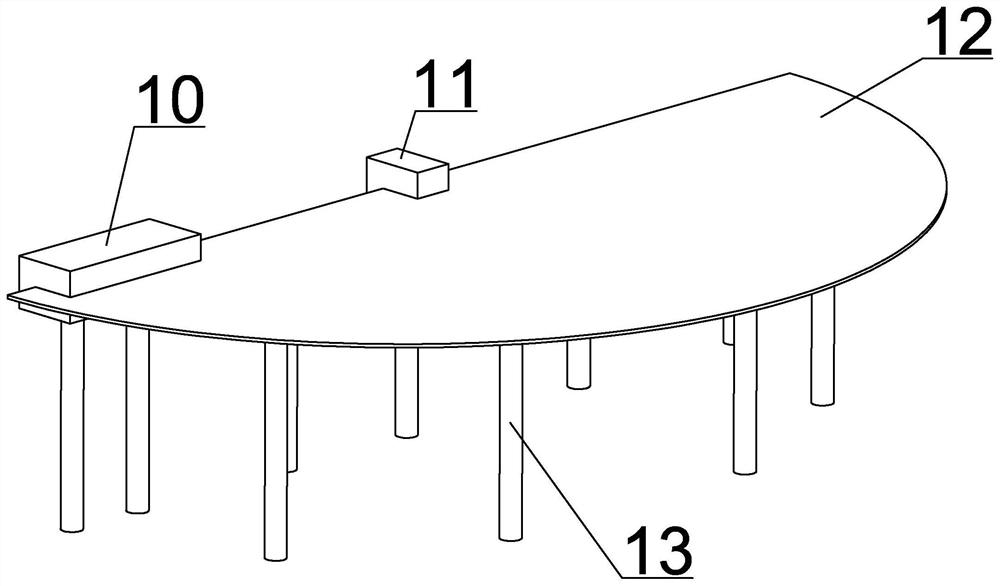

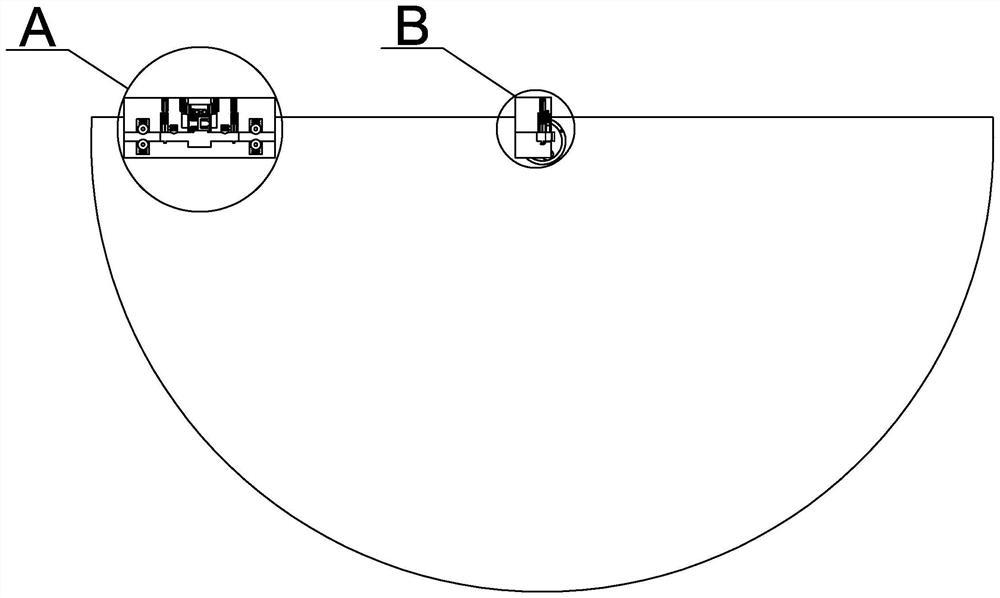

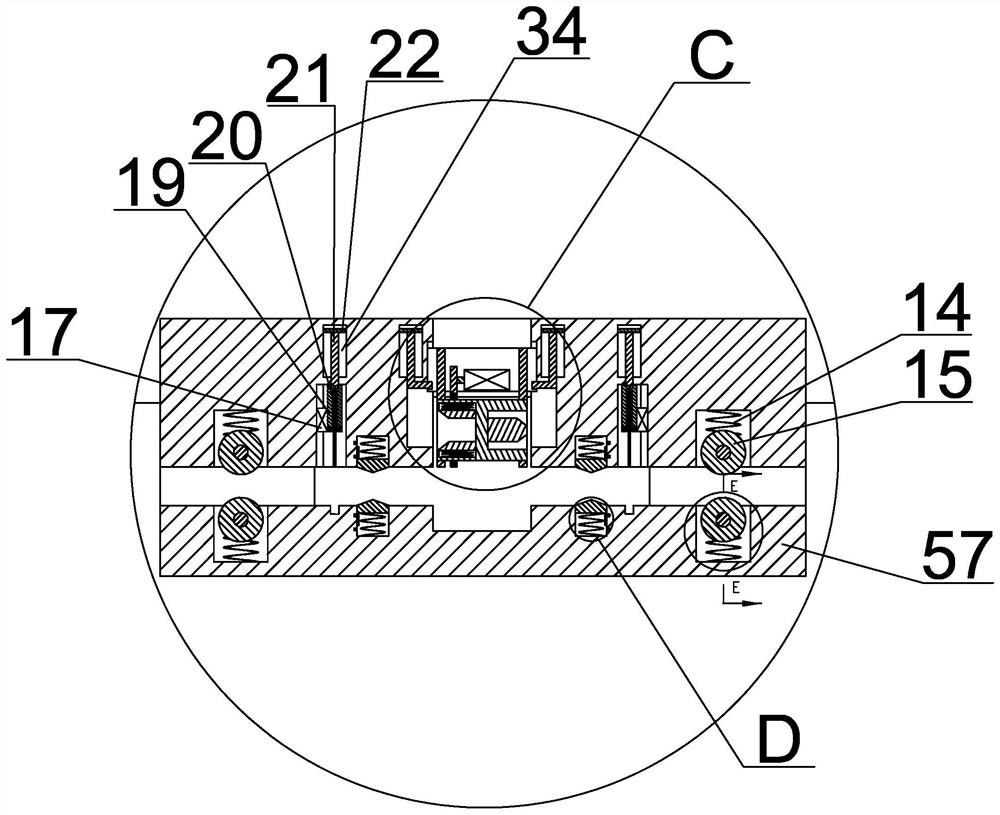

[0030] combine Figure 1-12 , a wooden door processing system using waste materials, including a support frame 13, the support frame 13 is composed of a plurality of round pipes, the end of the support frame 13 away from the ground is welded and fixed with an operation table 12, the operation table 12 is semicircular, and the operation table 12 is straight A binding forming part 11 is fixed in the center of the edge, a pretreatment part 10 is fixed on one side of the binding forming part 11, and a planing part is arranged in the center of the pretreatment part 10.

[0031] Further, there is a through groove inside the pretreatment part 10, the planing part is located on one side of the through groove, the bottom of the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com