Pin shaft dismounting and mounting device for coal mine hydraulic support

A coal mine hydraulic pressure and pin shaft technology, which is applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of affecting disassembly and assembly efficiency, troublesome disassembly and assembly, and limited operating space, so as to improve the convenience of operation and prevent The effect of moving and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Example: Please refer to Figure 1 to Figure 10 :

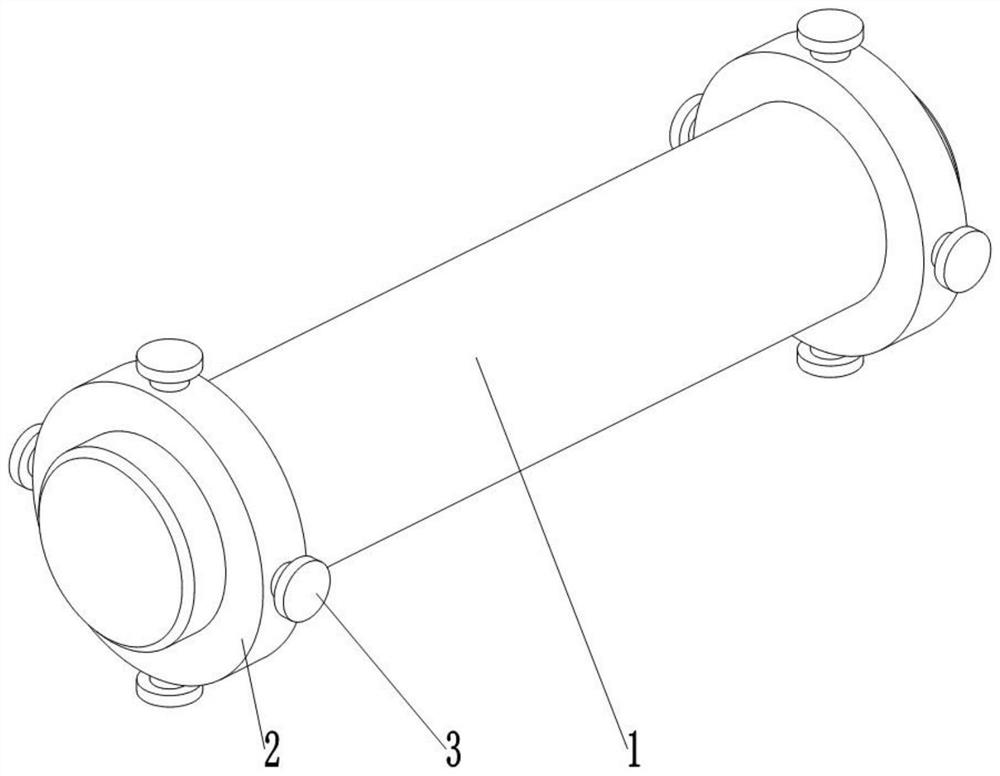

[0065] The present invention proposes a pin shaft device for coal mine hydraulic support disassembly and assembly, including: a pin shaft assembly and a disassembly assembly;

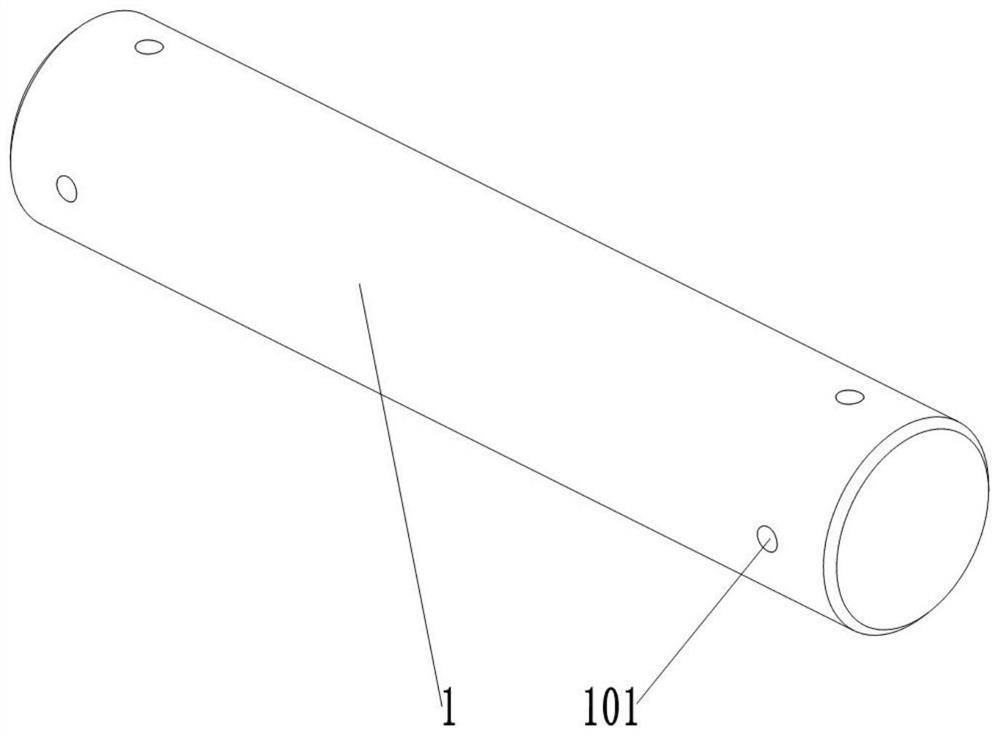

[0066] The pin assembly includes: a pin main body 1;

[0067] The pin main body 1 is a cylindrical pin structure;

[0068] Detachable block 2, the detachable block 2 is arranged on the left and right sides of the pin shaft main body 1;

[0069] The stopper positioning part 3, the stopper positioning part 3 is arranged in a circular array and plugged on the detachable block 2, and the detachable stopper 2 is plugged and connected with the pin main body 1 through the stopper locator 3; in addition, according to this Examples of inventions such as Figure 5 As shown, the pin shaft main body 1 also includes: stopper pin holes 101, which are arranged in a circular array on the left and right sides of the pin shaft main body 1; the stopper positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com