Integrated centrifugal system and method for full-automatic pelleter

A film making machine, fully automatic technology, applied in the direction of centrifuge, etc., can solve the problems of insufficient separation of cells and magazines, unsatisfactory centrifugation effect, and reduced accuracy of finished film production, so as to achieve firm fixation, complete separation, and improved The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

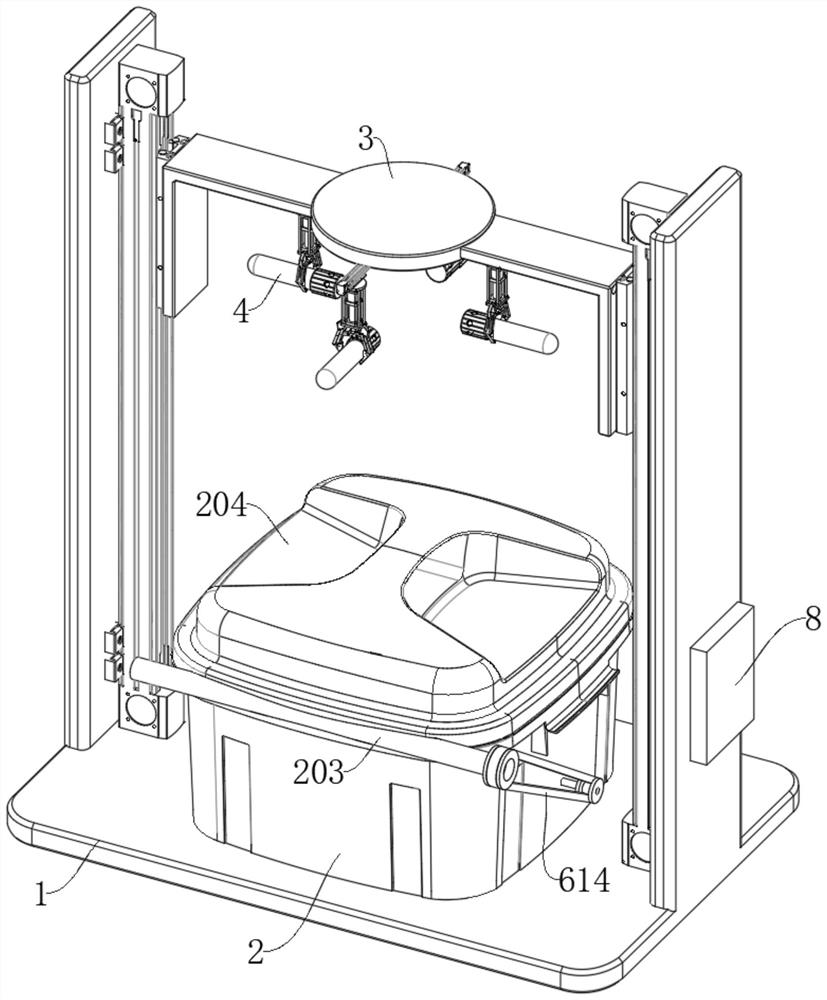

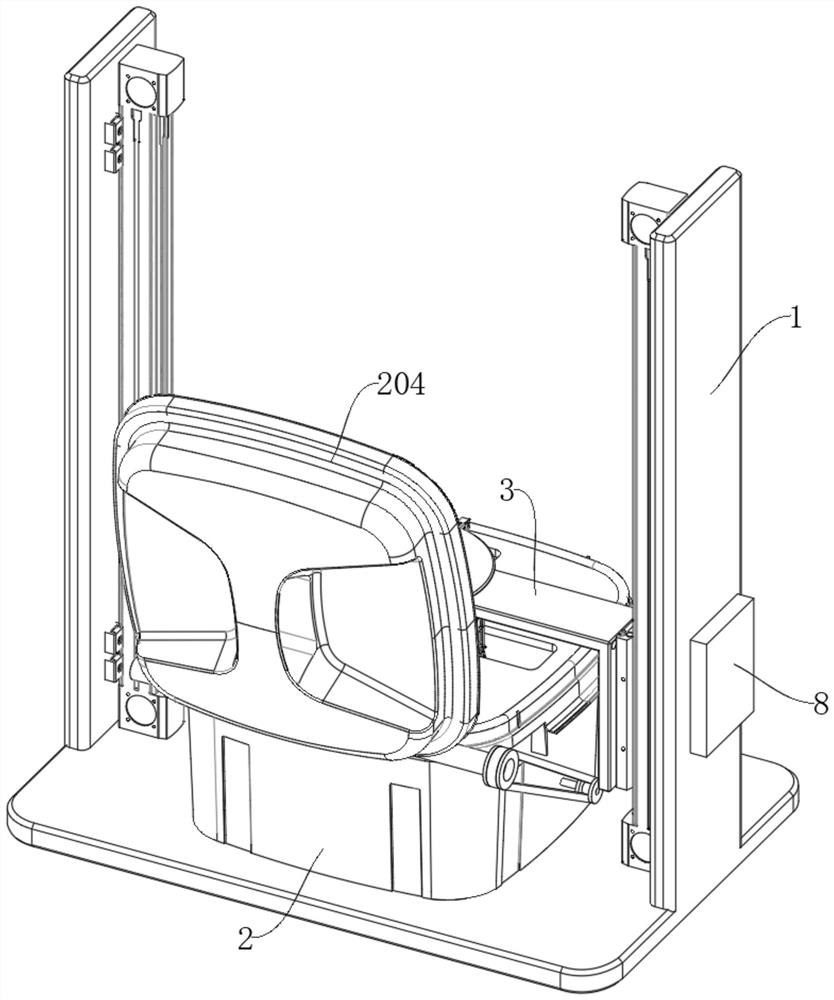

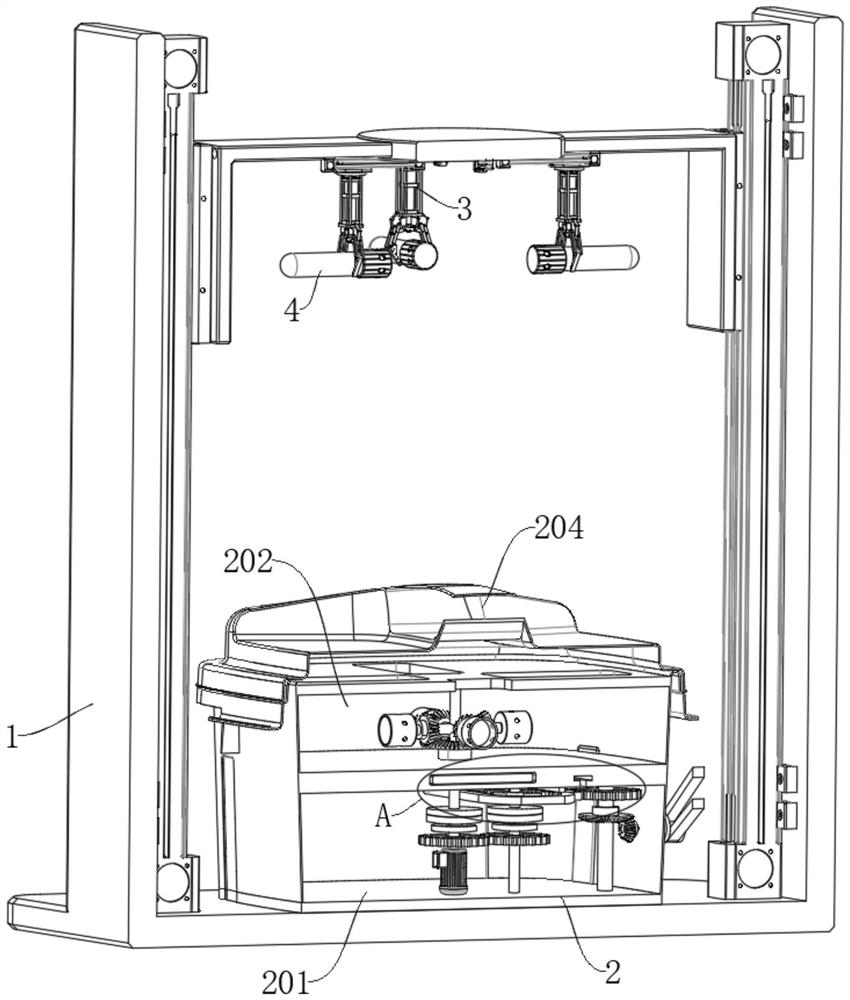

[0047] see Figure 1-10 , the present invention provides the following technical solutions:

[0048] Integrated centrifugation system for fully automatic tablet machines, including:

[0049] base1;

[0050] The housing 2 is fixedly connected to the upper end of the base 1, and the housing 2 is provided with a lower empty groove 201 and an upper empty groove 202;

[0051] The three-axis mobile robot arm 3 is fixedly connected to the upper end of the base 1;

[0052] A plurality of test tubes 4, and a plurality of test tubes 4 are installed on the three-axis mobile mechanical arm 3;

[0053] Centrifugal mechanism. The centrifugal mechanism includes a rotor 5, a first bevel gear 502, a plurality of sleeves 501 and a second bevel gear 503. The rotor 5 is rotatably connected to the upper inner wall of the upper slot 202, and the lower end of the rotor 5 moves through the lower space. The lower inner wall of the groove 201 extends downwards. A plurality of sleeves 501 are rotata...

Embodiment 2

[0078] The present invention also provides a method for using an integrated centrifugal system for a fully automatic tablet machine, which is used to better understand the method for using the integrated centrifugal system for a fully automatic tablet machine provided in the above-mentioned embodiment 1 or The principle is further explained, which is as follows

[0079] S1: First store the samples in multiple test tubes 4, then adjust the positions of multiple test tubes 4 so that multiple electric telescopic rods 403 are respectively aligned with multiple circular slots 404, and then install multiple test tubes 4 on the three-axis mobile On the robotic arm 3;

[0080] S2: After the installation of multiple test tubes 4 is completed, the servo motor 7 is firstly controlled to run forward by the PLC controller 8, and the servo motor 7 will drive the second rotating rod 605 to rotate through the transmission action of the two second spur gears 701, at this time Only one group o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com