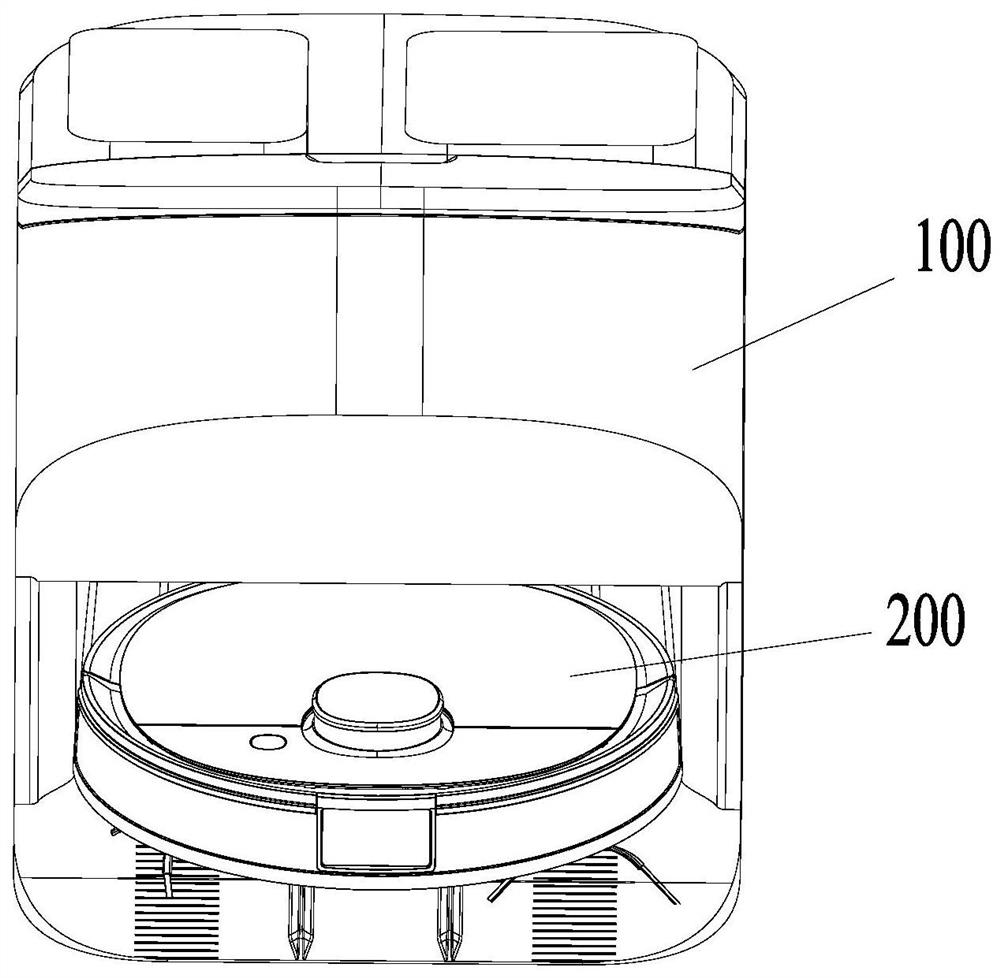

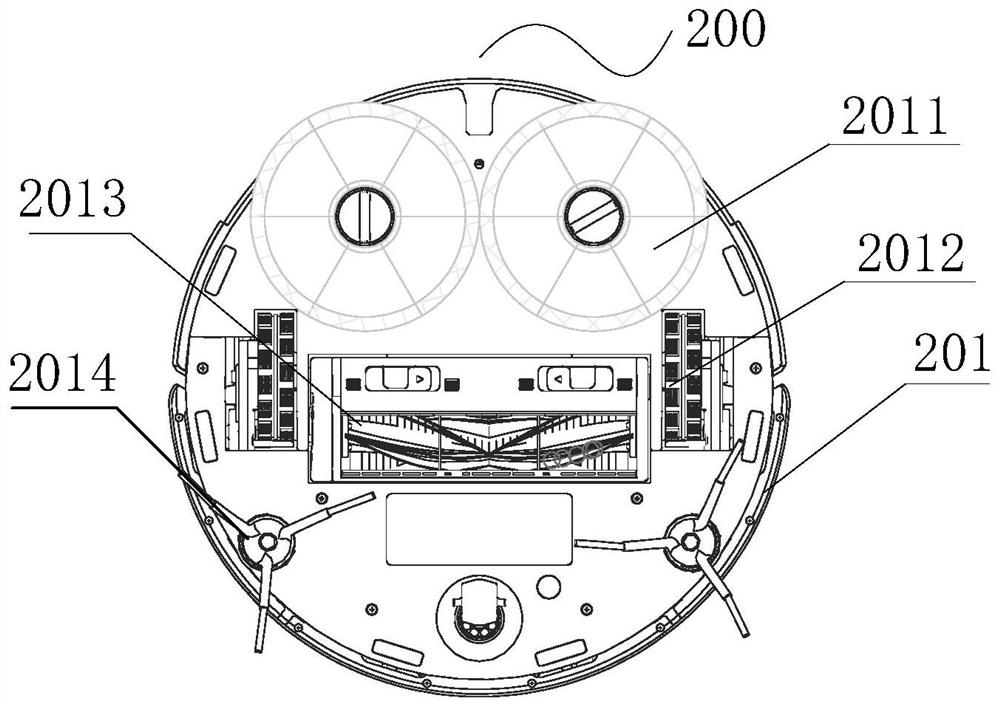

Workstation and working method thereof

A workstation and cleaning tank technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of reducing user experience, low cleaning efficiency, affecting the operation performance of cleaning robots, etc., to improve user experience, The effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

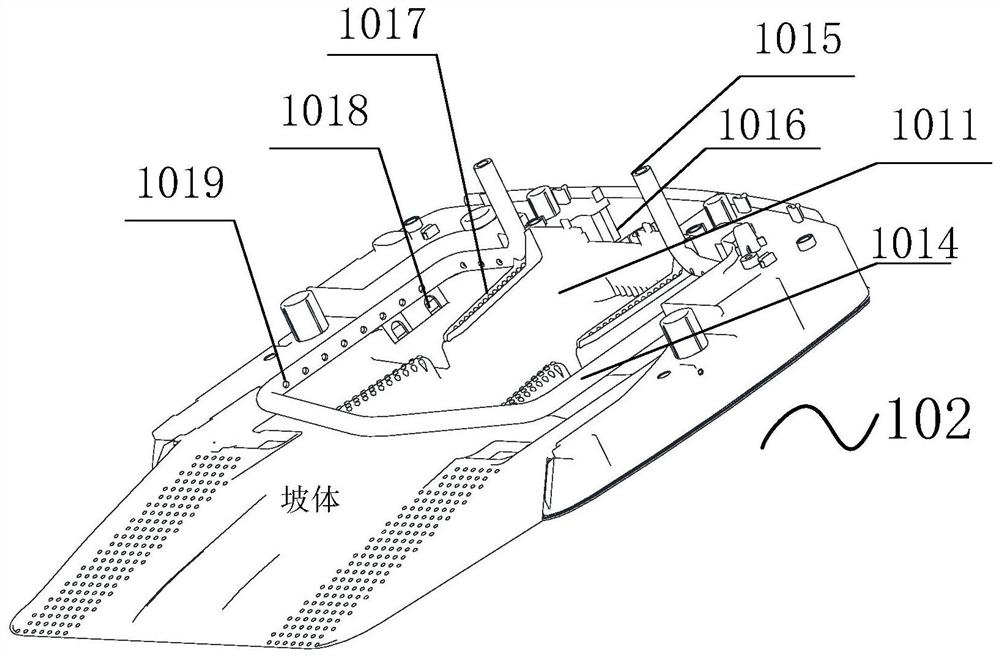

[0025] The present application provides the following embodiments to solve or partially solve the problems existing in the above-mentioned solutions. In order to enable those skilled in the art to better understand the solutions of the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

[0026] Some processes described in the specification, claims, and above-mentioned drawings of the present application contain multiple operations appearing in a specific order, and these operations may not be executed in the order in which they appear herein or executed in parallel. The serial numbers of the operations, such as 101, 102, etc., are only used to distinguish different operations, and the serial numbers themselves do not represent any execution order. Additionally, these processes can include more or fewer operations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com