Machining die for eyeliner bristle head

A technology for processing molds and eyeliners, which can be applied to brush hairs, household utensils, and cosmetic containers, etc. It can solve the problems of poor processing effect of eyeliner hair, poor positioning effect, and easy displacement of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

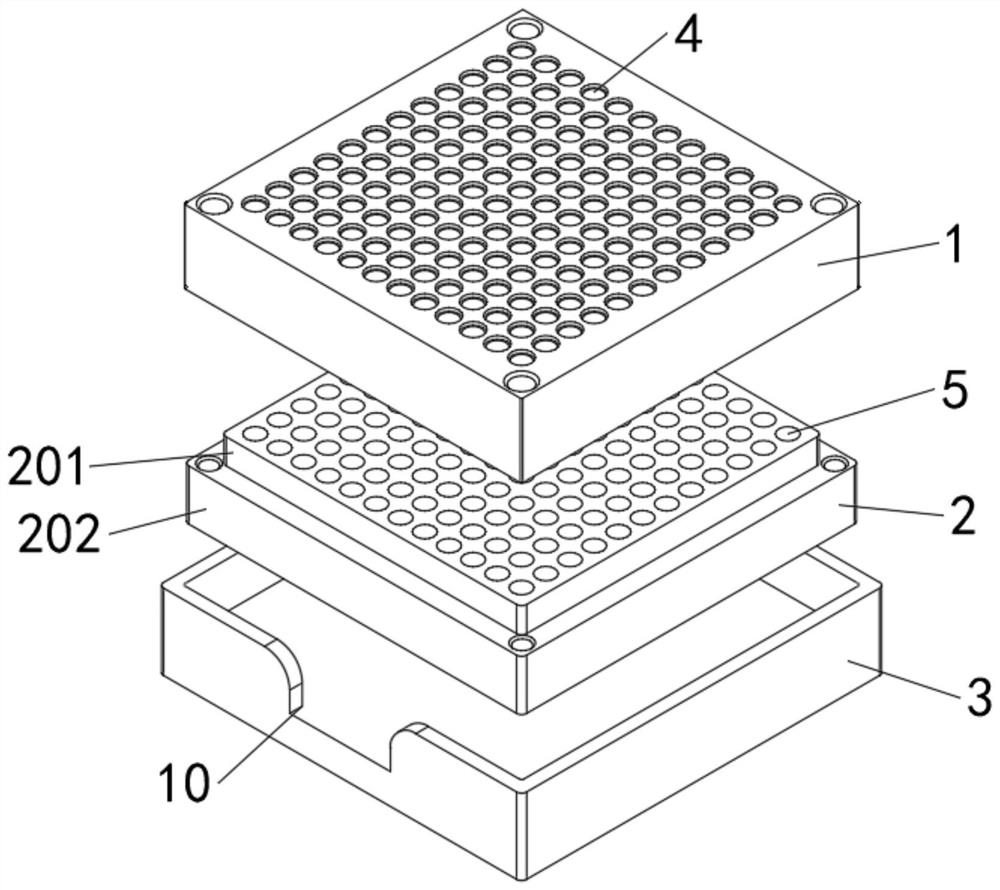

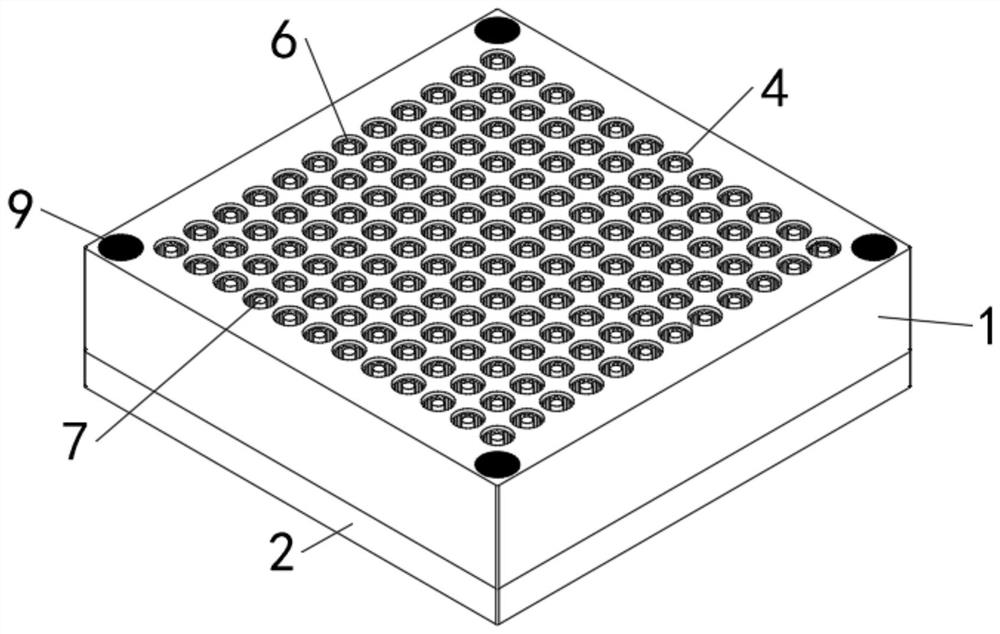

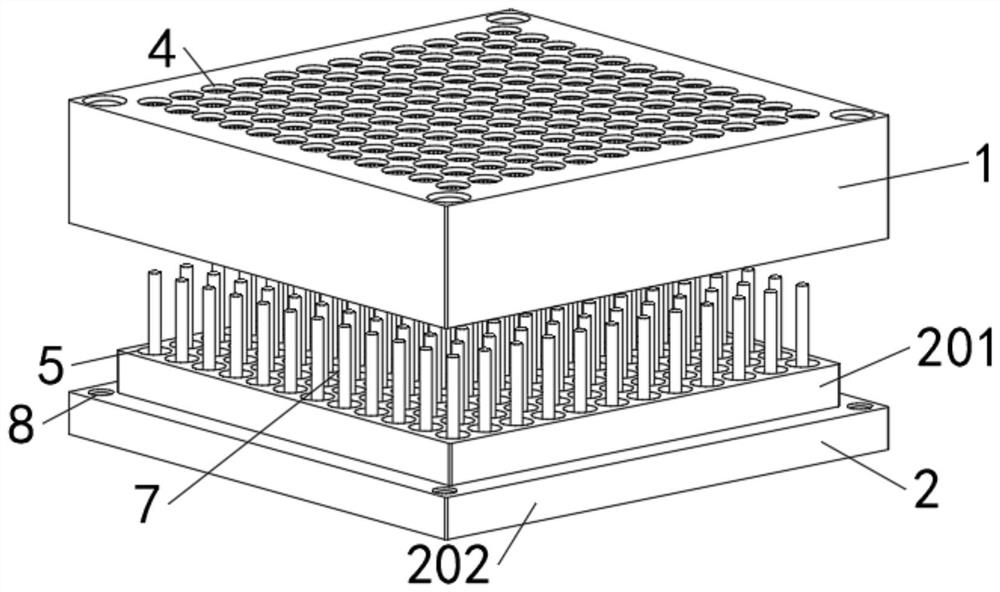

[0031] refer to Figure 1-Figure 4 , a kind of processing mold of eyeliner bristle, comprises upper mold body 1, lower mold body 2, mold bottom cover 3, is evenly provided with a plurality of through holes 4 on the upper mold body 1, and lower mold body 2 is formed by upper plate body 201 Composed of the lower plate body 202, the upper plate body 201 is provided with a plurality of guide holes 5 at the position corresponding to the through hole 4, and the ring tooth tube 6 is fixedly arranged in the through hole 4, and the ring tooth tube 6 can make the brush filament of the hair head There is no distortion during the production process. The guide hole 5 is provided with a guide post 7. The guide post 7 is used to avoid broken hairs when the hole is punched in the middle of the hair head in the later stage. It can also play a role in positioning the perforation at the center. The guide post 7 7 is stuck inside the ring tooth tube 6, and the four corners of the upper mold body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com