Broken soft thin coal seam gas extraction directional long drilling construction drilling tool assembly and method

A gas extraction and drilling tool combination technology, which is used in directional drilling, gas discharge, mining equipment, etc., can solve the problems of difficulty in opening branch holes, shallow hole depth, easy to reach the top or bottom, etc., and shorten the treatment time. Cycle and treatment costs, improve hole depth and hole rate, and avoid the effect of branching operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

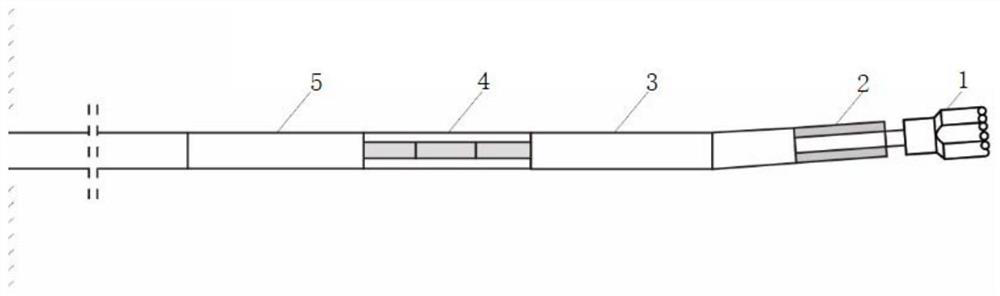

[0046] This embodiment provides a drilling tool assembly for directional long drilling construction of gas drainage in soft and thin coal seams, such as Figure 1 to Figure 7 As shown, it includes a directional drill bit 1, a front measuring sub 2, a non-magnetic over-the-line screw drilling tool 3, a rear measuring sub 4 and a central cable drill pipe 5 connected in sequence from bottom to top.

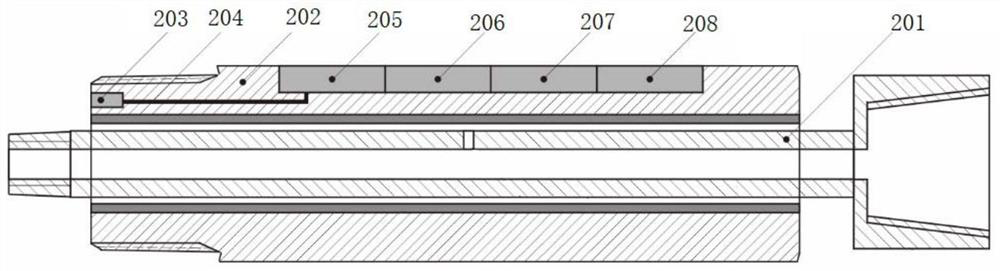

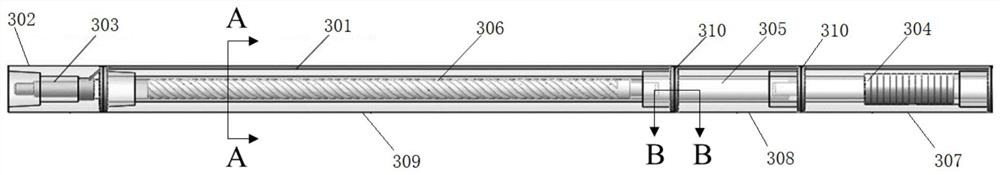

[0047] The front measuring puppet 2 includes a transmission center shaft 201 with a central through hole, a front measurement pup outer tube 202 sleeved outside the transmission center shaft 201, and a communication measurement unit arranged on the front measurement pup outer tube 202; The magnetic over-the-line screw drilling tool 3 includes a central power unit, a non-magnetic drilling tool outer tube sleeved outside the central power unit, a communication cable assembly 301 embedded in the non-magnetic drilling tool outer tube, a communication nipple outer tube 302 and a The side ...

Embodiment 2

[0062] A directional long drilling construction method for gas drainage in broken and soft thin coal seams, the method is realized by the construction drilling tool assembly in embodiment 1; comprising the following steps:

[0063] Drilling trajectory design before construction: collect geological information in the gas drainage drilling construction area, which includes adjacent construction drilling data, ground exploration information, geological structure information revealed by roadway excavation, etc., and establish gas drainage based on the geological information The initial 3D geological model within the scope of the drilling area; design the drilling trajectory in the initial 3D geological model to ensure that the drilling trajectory extends in the thin coal seam;

[0064] Step 1: Measurement of drilling trajectory parameters and formation natural gamma ray radioactive intensity: During drilling, use the engineering parameter measurement unit in the pre-measurement nip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com