Metal hydroxide hydrothermal C-composite OER material prepared by using hydrothermal method

A technology of hydroxide and hydrothermal method, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor stability, achieve high stability, increase specific surface area, and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

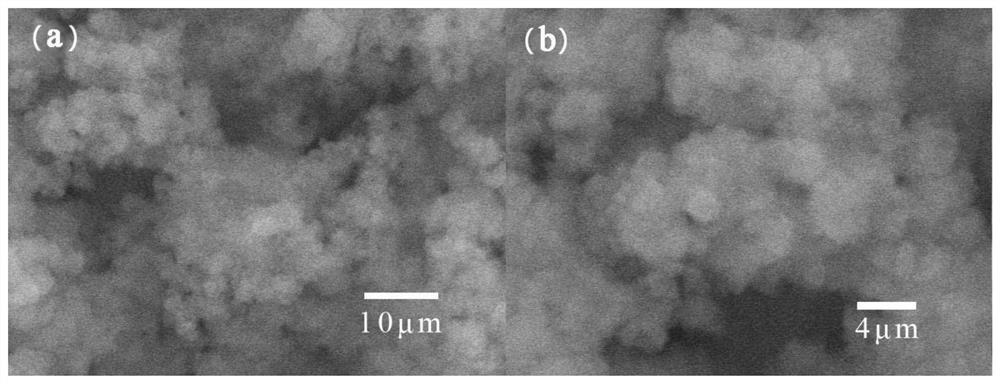

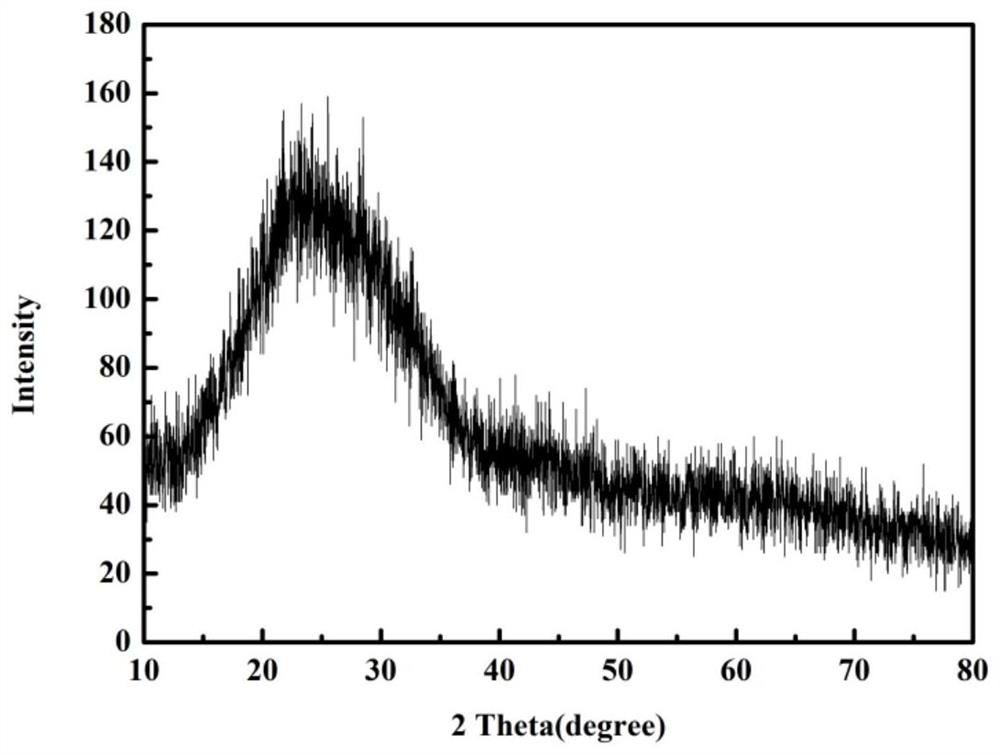

[0027] Such as Figure 1-2 As shown, the embodiment of the present invention provides a metal hydroxide hydrothermal C-composite OER material prepared by a hydrothermal method, and a method for preparing a metal hydroxide hydrothermal C-composite OER material, comprising the following steps:

[0028] S1. Configuration solution

[0029] Weigh 44mL, 40mL, 32mL and 24mL of 10mmol glucose and 11mL, 10mL, 8mL and 6mL of 2.5mmol anhydrous phloroglucinol respectively into four different beakers, then slowly add metal salts into the beakers, and then Add 5mL, 10mL, 20mL, and 30mL of acetic acid into the four beakers respectively, stir the beakers at a speed of 100r / min for 30min, and prepare a 60mL aqueous solution;

[0030] S2. Hydrothermal reaction

[0031] Take out the prepared aqueous solution and put them into the hydrothermal kettle respectively, and stir the hydrothermal kettle at a speed of 400r / min for 35min, and at the same time, carry out hydroheating in the hydrothermal ...

Embodiment 2

[0041] Such as Figure 1-2 As shown, the embodiment of the present invention provides a metal hydroxide hydrothermal C-composite OER material prepared by a hydrothermal method, and a method for preparing a metal hydroxide hydrothermal C-composite OER material, comprising the following steps:

[0042] S1. Configuration solution

[0043] Weigh 32mL 10mmol of glucose and 8mL of 2.5mmol anhydrous phloroglucinol into four different beakers, then take three of them and add FeSO4·7H2O, CoSO4·7H2O and MnSO4·H2O respectively, the molar amount All were controlled at 0.25mmol, then 20mL of acetic acid was added to the four beakers, and the beakers were stirred at a speed of 50-100r / min for 25-30min to prepare 60ml of aqueous solution;

[0044] S2. Hydrothermal reaction

[0045] Take out the prepared aqueous solution and put it into the hydrothermal kettle, and stir the hydrothermal kettle at a speed of 200r / min for 30min, and at the same time, heat the hydrothermal kettle at a temperat...

Embodiment 3

[0055] Such as Figure 1-2 As shown, the embodiment of the present invention provides a metal hydroxide hydrothermal C-composite OER material prepared by a hydrothermal method, and a method for preparing a metal hydroxide hydrothermal C-composite OER material, comprising the following steps:

[0056] S1. Configuration solution

[0057] The glucose of 32ml 10mmol and the anhydrous phloroglucinol of 8ml 2.5mmol were weighed respectively and put into four different beakers, and FeSO4·7H2O of 0.25mmol, 0.5mmol, 0.75mmol and 1mmol were added respectively in the four beakers, Then add 20mL of acetic acid, stir in the beaker at a speed of 100r / min for 30min, and prepare a 60mL aqueous solution;

[0058] S2. Hydrothermal reaction

[0059] Take out the prepared aqueous solution and put it into the hydrothermal kettle, and stir the hydrothermal kettle at a speed of 200r / min for 30min, and at the same time, heat the hydrothermal kettle at a temperature of 200°C, and the hydrothermal ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com