Multifunctional system and method for preparing two-dimensional material micro-nano device

A two-dimensional material and multi-functional technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high price, large volume, and poor compatibility with the use environment, and achieve low price, good compatibility, and multiple realizations. The effect of functional reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

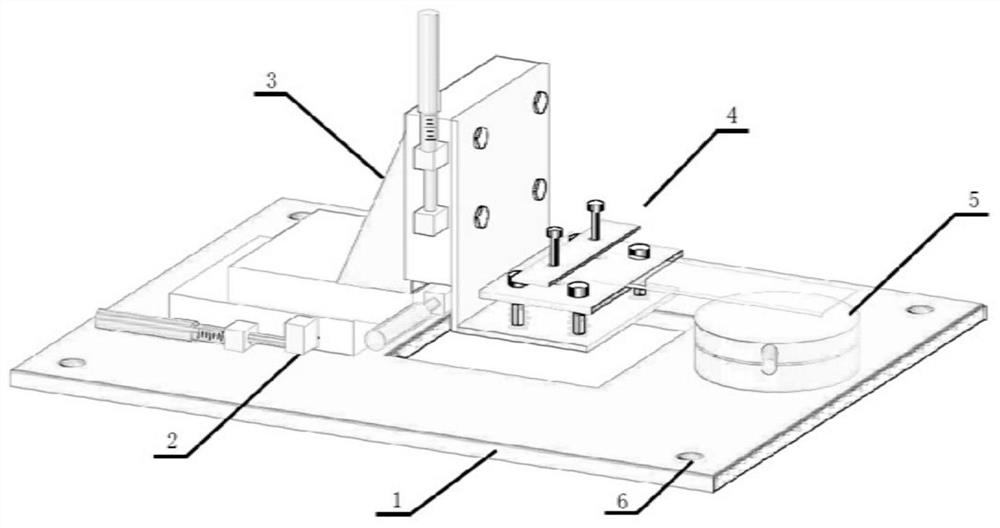

[0036] like figure 1 As shown, the present invention provides a multifunctional system for the preparation of two-dimensional material micro-nano devices. The multifunctional system includes a fixed base 1 , a displacement module 2 , an adapter plate 3 , a multifunctional conversion module 4 , a base fixed rotation module 5 , and screw holes 6 .

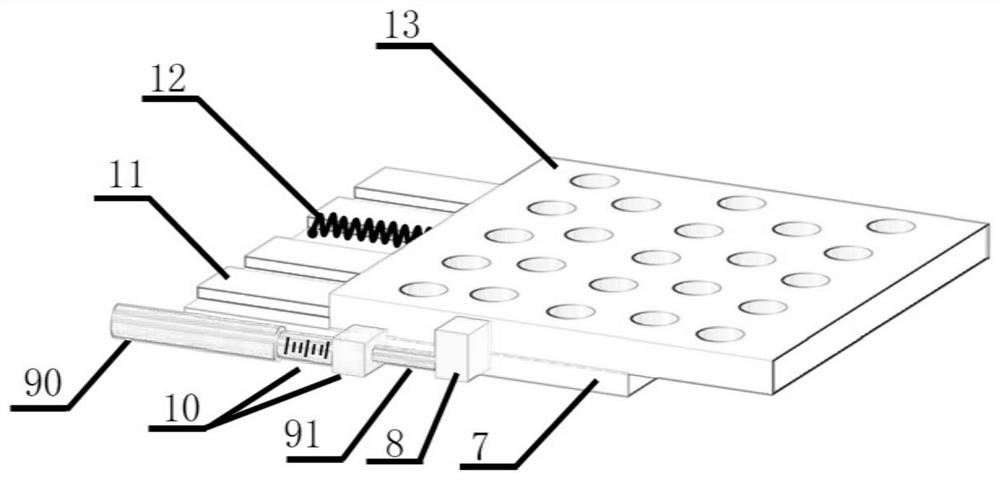

[0037] like figure 2 As shown, the single-axis translation stage includes a lower panel 7 , an upper panel 13 , an adjustment shaft 90 , a screw 91 , a screw fixing sleeve 10 , a screw jack 8 , a guide rail 11 , and a tension spring 12 . Each single-axis translation stage can independently realize linear movement in X, Y, and Z directions. The rotation adjustment shaft 90 can drive the screw rod 91 to move, and the movement of the screw rod 91 can push the top column of the screw rod to move, thereby driving the movement of the upper panel of the single-axis translation stage. The tension spring produces a force that is opposite ...

Embodiment 2

[0043] The first is the dry transfer of 2D crystalline materials.

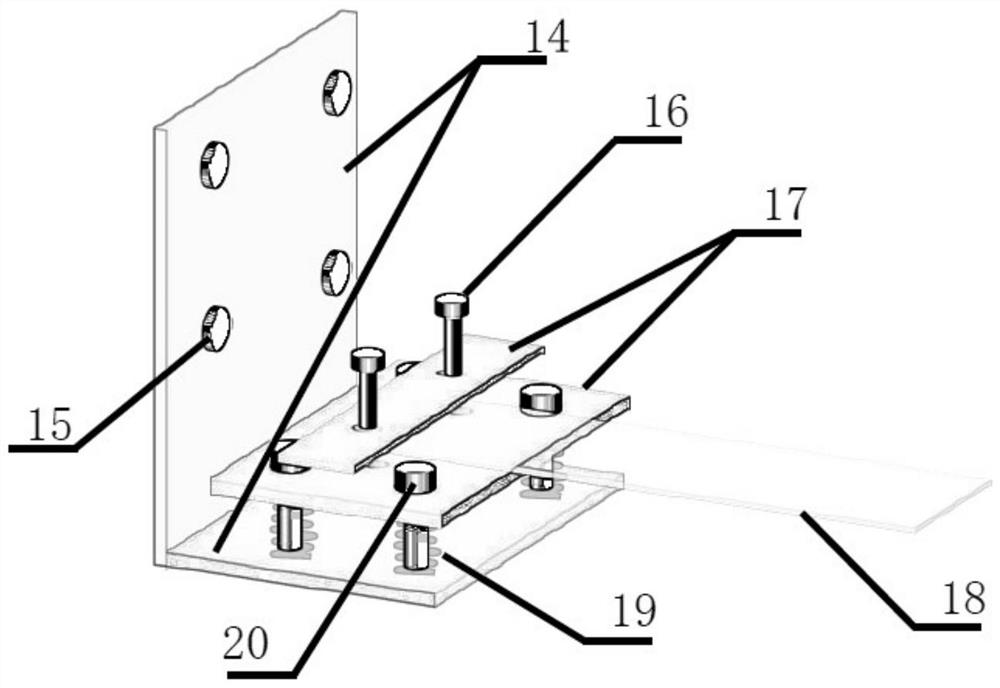

[0044] like Figure 5-6 As shown, the cleaned Si / SiO 2 The base is fixed on the base fixed rotating module of the multifunctional system, and the PDMS glued with the two-dimensional crystal material is fixed on the lower surface of the multifunctional conversion sheet of the multifunctional system. Under microscope observation, adjust the displacement module of the multifunctional system (including the X, Y, Z directions of the single-axis translation stage) and the levelness or inclination angle of the multifunctional conversion plate; use the base to fix the rotation module to adjust the two-dimensional crystal material and Si / SiO 2 The relative angle between the substrates; under the above operation, adjust the 2D crystal material and Si / SiO 2 The relative position and distance between the substrates, and making the 2D crystal material and Si / SiO 2 The base is close; if Figure 7 As shown, adjust the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com