Intelligent steel bar bender for machining lower side cabinet hinge

A steel bar bending and intelligent technology, applied in the field of intelligent steel bar bending machine, can solve the problems of uncontrollable angle, unsuitable for the production of lower side door hinges, etc., to meet the requirements of processing accuracy and assembly requirements, and ensure the effect of regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

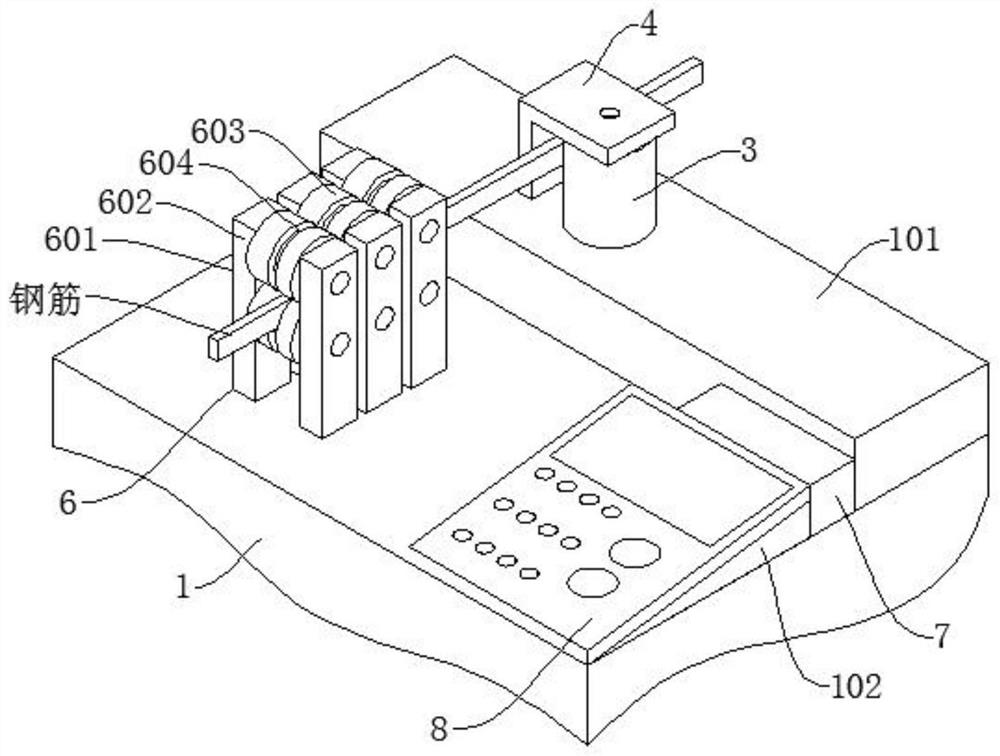

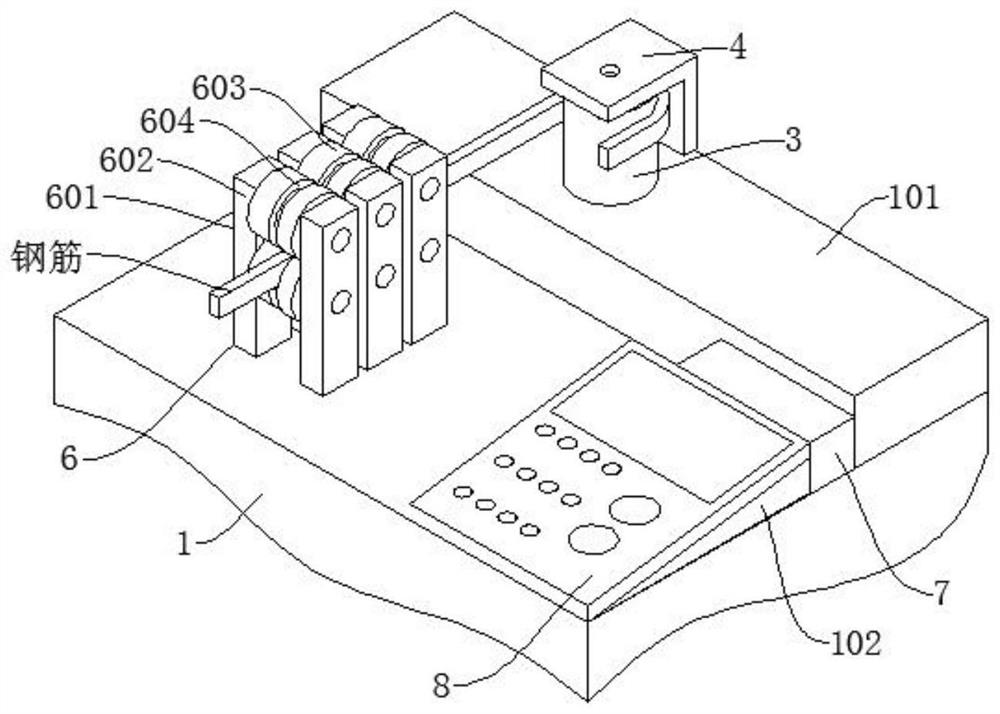

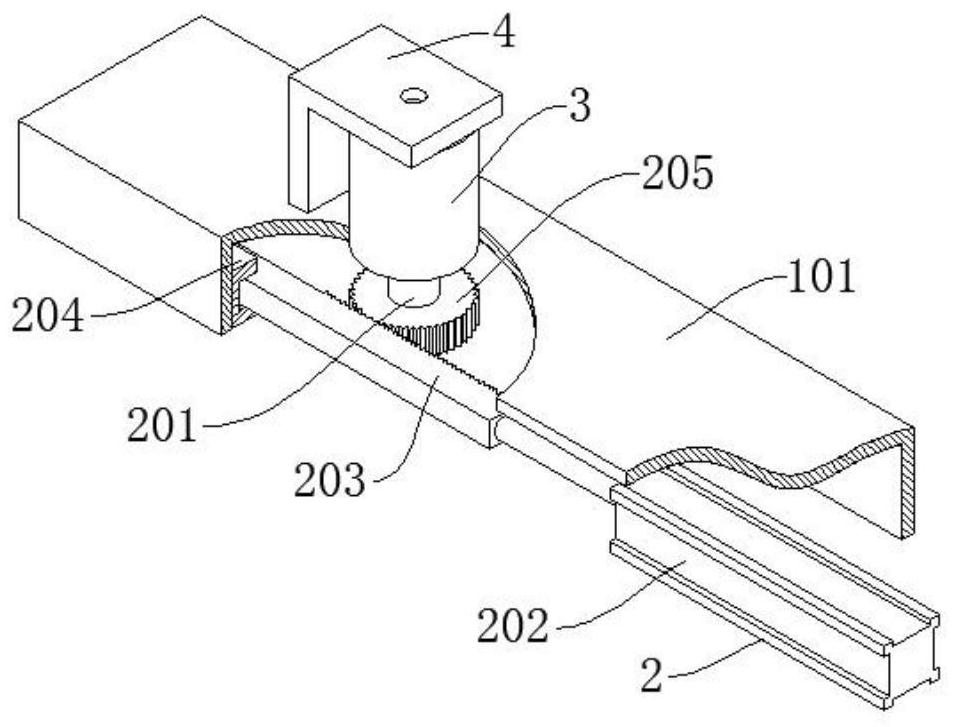

[0031] Such as figure 1 and figure 2 As shown, an intelligent steel bar bending machine for processing lower side door hinges includes a steel bar bending machine body 1, a support box 101 is installed at the front side edge of the upper surface of the steel bar bending machine body 1, and a support box 101 is installed in the support box 101. A bending drive mechanism 2 is installed, and a relief hole is penetrated above the support box 101. The drive shaft 201 of the bending drive mechanism 2 is inserted into the lower end of the bending shaft 3 through the relief hole, and the bending drive mechanism 2 is driven by The shaft 201 drives the bending shaft 3 to rotate positively and negatively. The upper end of the bending shaft 3 is installed with a limit plate 4 through a positioning nail 5. The limit plate 4 is an L-shaped structural plate. The vertical side plate of the limit plate 4 602 faces to the left, a curved feed inlet is formed between the vertical side plate 602...

specific Embodiment 1

[0049] Assuming that the steel bar type has been determined, replace the bending shaft, transmission gear, and transmission rack of the corresponding size. If the radius r of the bending shaft is 5cm, the central angle of the bending angle is 60°. According to the above structure and calculation method, it can be obtained:

[0050]

[0051] Then L=5.23, which means that the moving length of the pressure cylinder pulling the rack is 5.23cm.

[0052] Verify that the above specific embodiment 1 is: the bending axis radius r is 5cm, then the circumference C=2πr, which is 31.4cm, and the calculation formula of the central angle of the bending angle is:

[0053]

[0054] Then n=60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com