Test tube cleaning equipment for blood department

A technology for cleaning equipment and departments, applied in the field of test tube cleaning equipment, can solve problems such as low cleaning efficiency and incomplete test tubes, and achieve the effects of improved cleaning efficiency, convenient handling, and accelerated drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

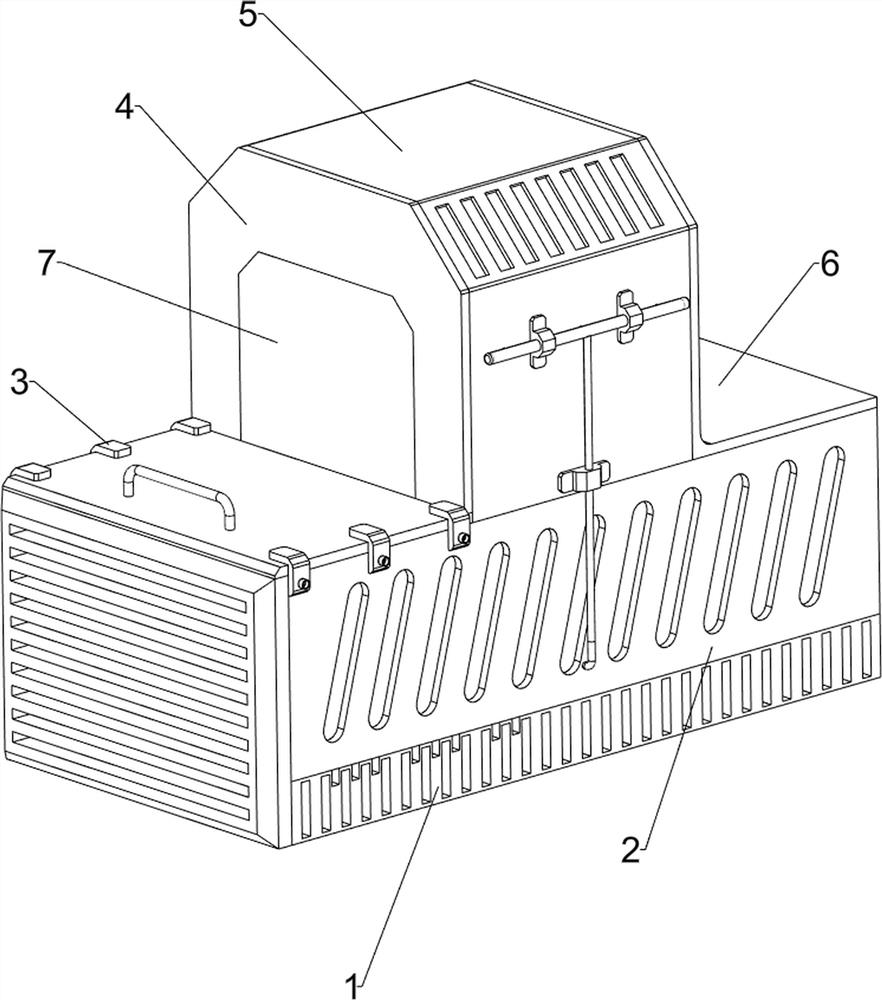

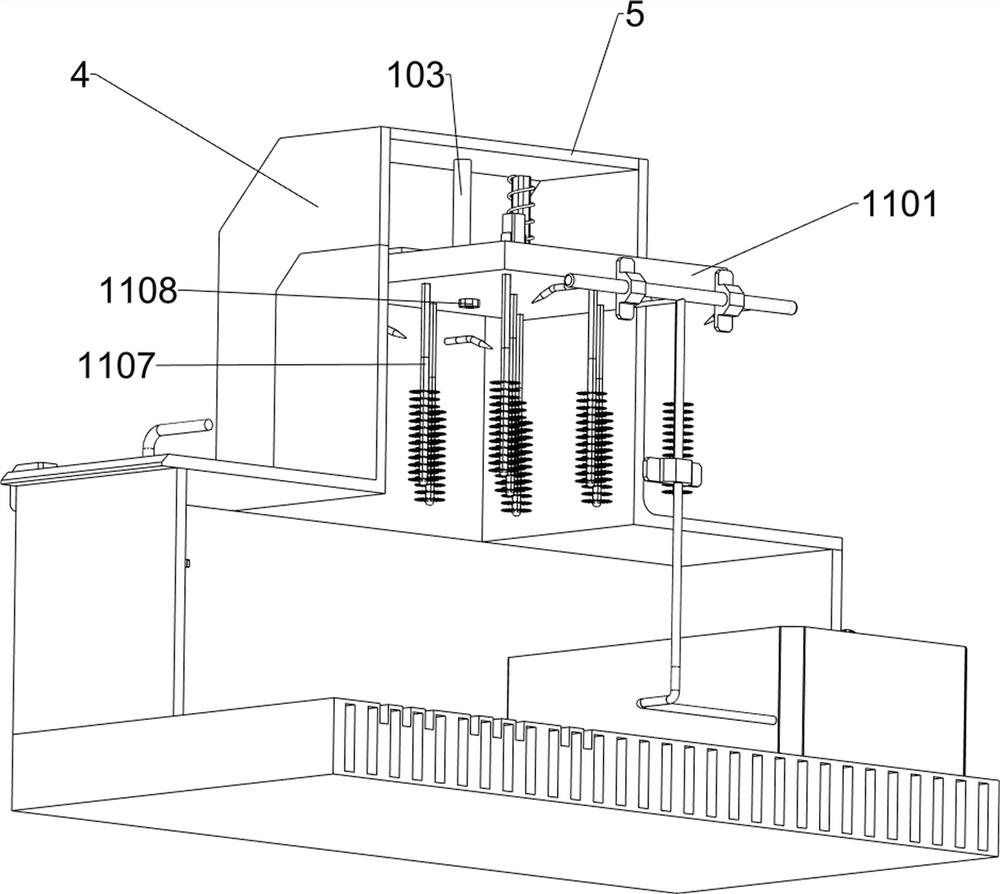

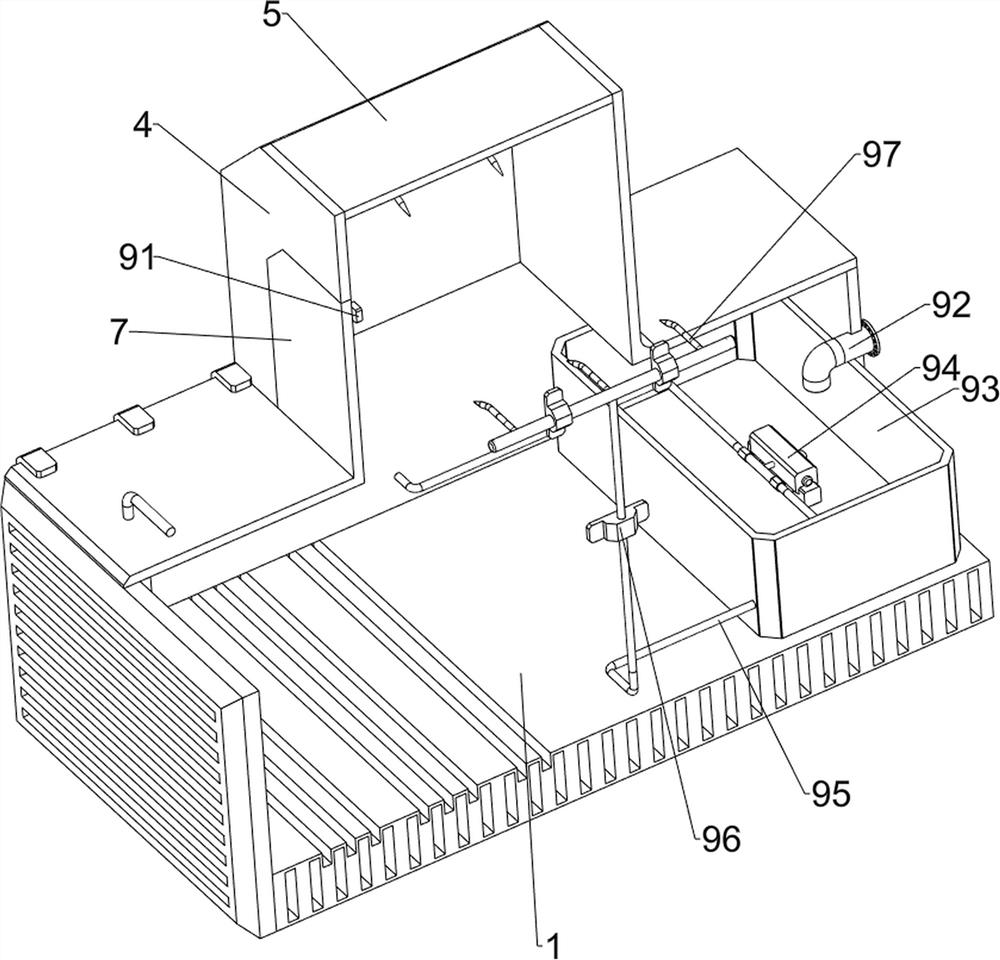

[0031] A kind of test tube cleaning equipment for blood department, such as Figure 1-5 As shown, it includes a base plate 1, a coaming plate 2, a limit buckle 3, a front baffle 4, a frame 5, a rear baffle 6, a pull plate 7, a water spray mechanism 9, a telescopic mechanism 10 and a cleaning mechanism 11, and the base plate 1 There is a shroud 2 inside, and three limit buckles 3 are arranged symmetrically front and rear on the upper left side of the shroud 2, a rear baffle 6 is arranged on the right side of the top of the shroud 2, a front baffle 4 is arranged on the left side of the top of the shroud 2, and the front A frame 5 is provided between the baffle 4 and the rear baffle 6, the bottom of the frame 5 is connected in the middle of the top of the enclosure 2, and a pull plate 7 is placed slidingly on the left side of the top of the enclosure 2, and the pull plate 7 is in contact with the limit buckle 3 , Water spray mechanism 9 is provided between base plate 1 and coamin...

Embodiment 2

[0037] On the basis of Example 1, such as image 3 , Figure 6 , Figure 7 and Figure 8 As shown, a moving mechanism 12 is also included, and the moving mechanism 12 includes a third mounting block 1201, a second electric push rod 1202, a guide groove 1203, a rack 1204 and a second distance sensor 1205, and the front and rear of the right side of the enclosure 2 The third mounting block 1201 is symmetrically arranged on both sides, and the second electric push rod 1202 is arranged between the third mounting block 1201 on the same lateral side. The left and right sides of the enclosure 2 are symmetrically provided with a guide groove 1203, and the guide groove The right side of 1203 is provided with a rack 1204, and the top of the left side of the second electric push rod 1202 on the rear side is provided with a second distance sensor 1205.

[0038] Also includes a fixed mechanism 13, the fixed mechanism 13 includes a connecting frame 1301, a fixed snap ring 1302, a rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com