Workpiece vibrating screen based on magnetic rotation ultrasonic waves

A vibrating screen and ultrasonic technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of increasing the time of switching the vibrating screen, increasing the processing time of the user, reducing the practicality of the vibrating screen, etc., so as to enhance the practicality. , prolong the service life, reduce the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

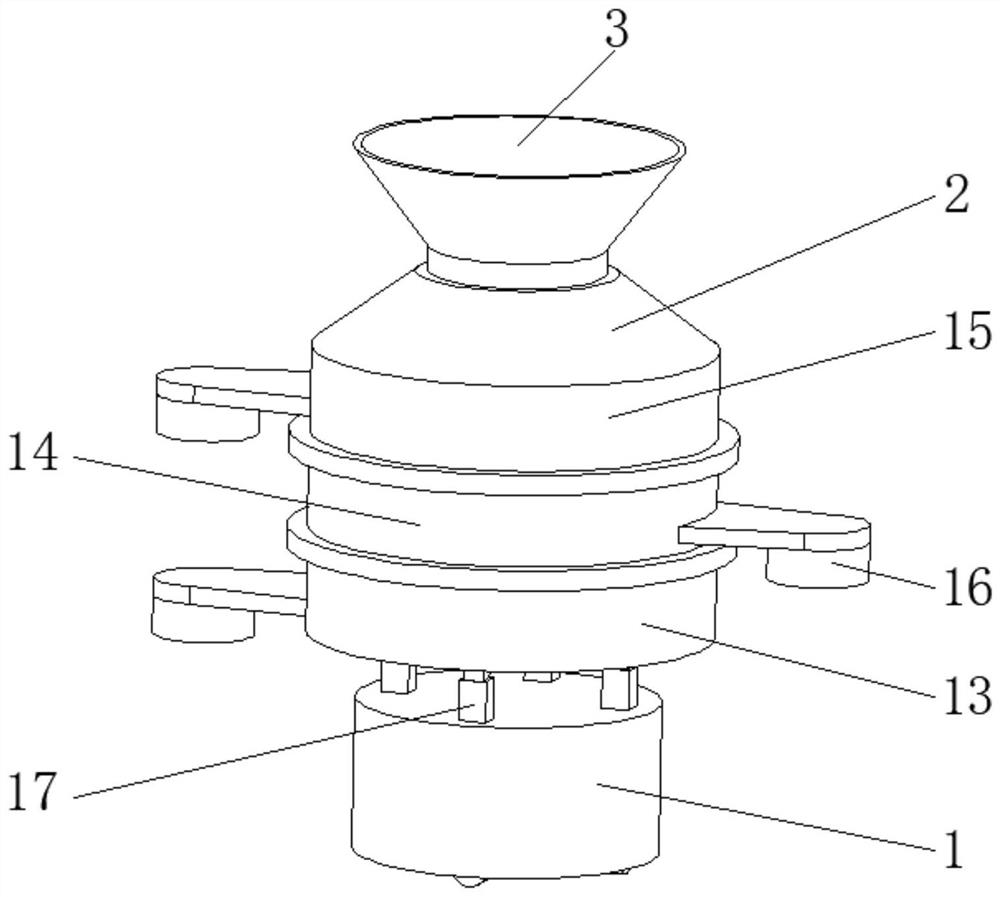

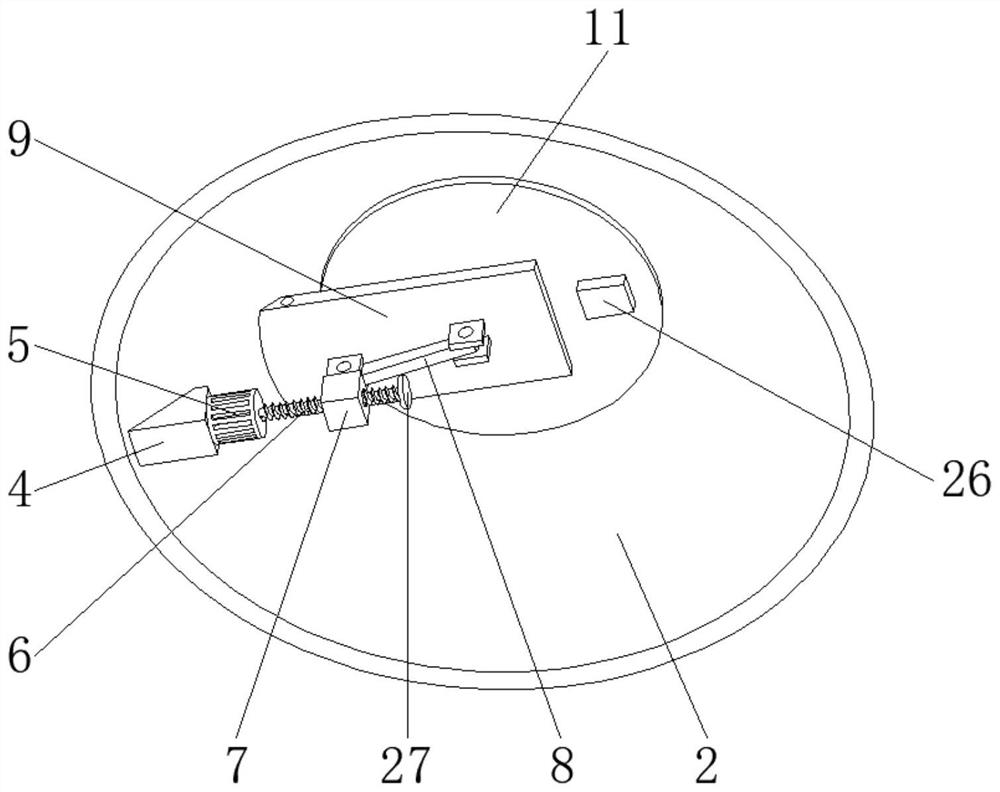

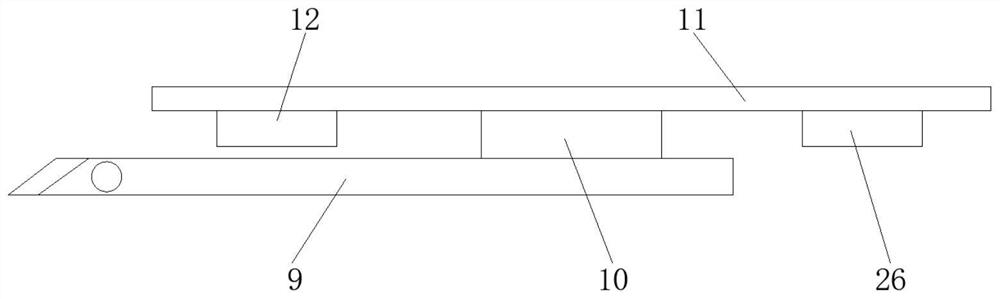

[0027] Such as Figure 1-6 As shown, the present invention provides a workpiece vibrating screen based on magnetic rotation ultrasonic waves, including a base 1 and a sieve body, and the sieve body includes a first vibrating screen 13, a second vibrating screen 14 and a third vibrating screen 15, and the second vibrating screen 14 Set directly above the first vibrating screen 13, the third vibrating screen 15 is located directly above the second vibrating screen 14, and the top surface of the third vibrating screen 15 is fixed with a dust cover 2 to prevent dust from scattering around during the vibrating screening process. The sieve size of a vibrating screen 13, the second vibrating screen 14 and the third vibrating screen 15 increases successively. According to needs, the materials of different size particles are screened out respectively. The first vibrating screen 13, the second vibrating screen 14 and the third vibrating screen One side of the three vibrating screens 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com