Asphalt mixing and stirring device and stirring method thereof

A technology of mixing and mixing and asphalt, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems that asphalt concrete cannot be mixed evenly, and cannot be dispersed, so as to prevent cracks or collapse and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

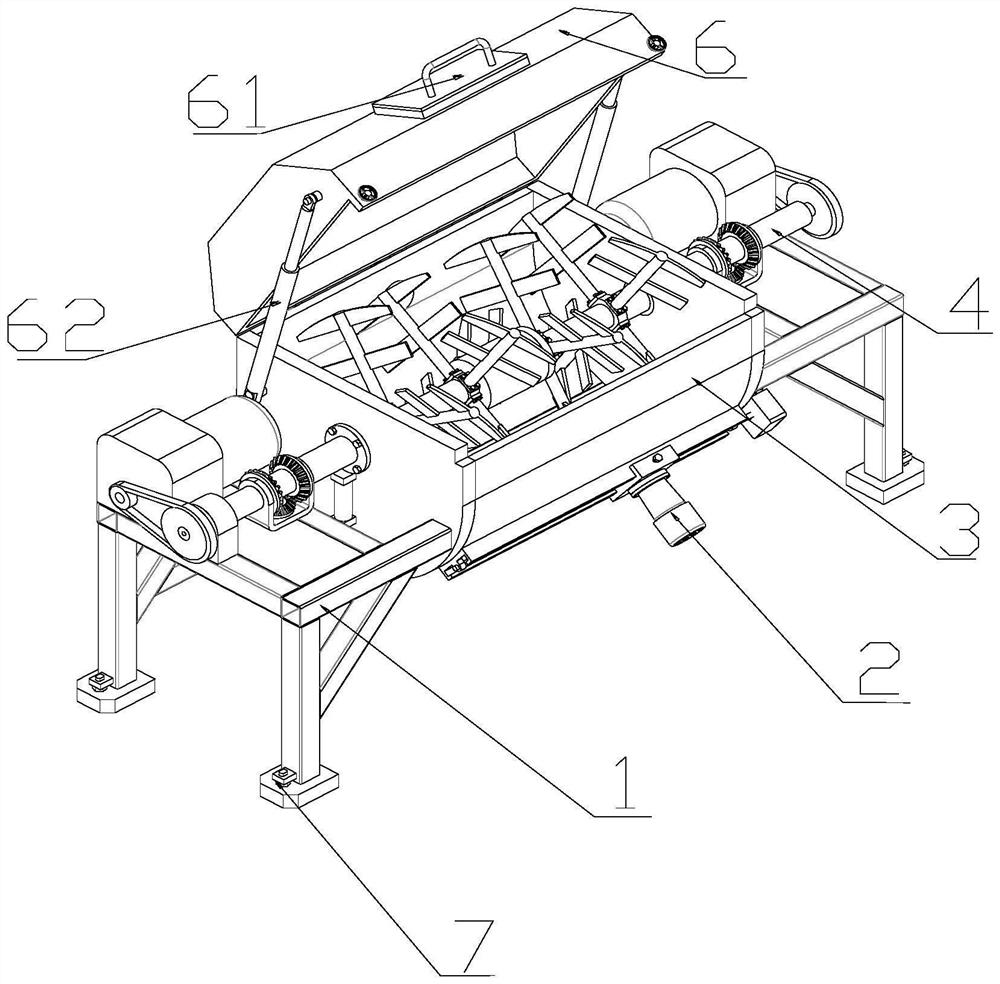

[0043] see figure 1 , figure 2 and Figure 5 , the present embodiment is used for the asphalt mixing and stirring device, which includes a box vibrating mechanism 2, a stirring box 3, a forward and reverse stirring mechanism 4 and a shaft vibrating mechanism 5, and the box vibrating mechanism 2 is along the length direction of the mixing box 3 It is connected to the outside of the box wall of the mixing box 3, and the box vibration mechanism 2 can move along the length direction of the mixing box 3, which is convenient for vibrating at different parts of the mixing box 3, and the structure of the asphalt concrete near the inside of the mixing box 3 The blocks are broken up, and the forward and reverse stirring mechanism 4 and the shaft vibration mechanism 5 are all placed in the inner cavity of the mixing box 3. The forward and reverse stirring mechanism 4 can be vibrated through the shaft vibration mechanism 5, and the forward and reverse stirring mechanism The agglomerati...

Embodiment 2

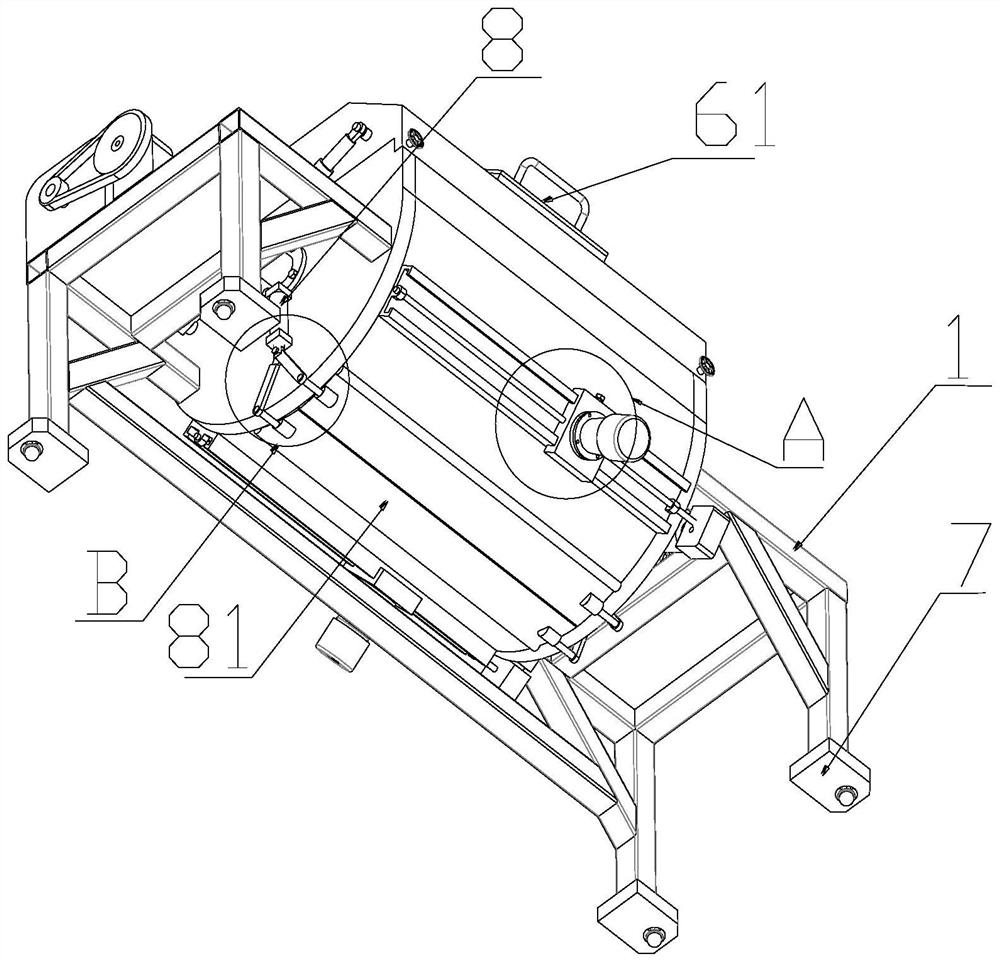

[0046] see Figure 7 and Figure 8 , this embodiment is used for asphalt mixing and stirring device, on the basis of embodiment 1, its forward and reverse stirring mechanism 4 includes stirring drive member 401, transmission member 402, forward rotation shaft 403, gear transmission assembly 404, reverse rotation The rotating sleeve 405, the reverse stirring paddle 406 and the forward stirring paddle 407, the stirring drive part 401 and the transmission part 402 are all arranged on the outside of the stirring box 3, and the stirring drive part 401 is fixedly connected with the top of the support frame body 1, and the stirring drive The power output end of the part 401 is connected with the power input end of the transmission part 402, and the power output end of the transmission part 402 is connected with one end of the forward rotation shaft 403, and the other end of the forward rotation shaft 403 passes through the tank of the stirring tank 3. The wall is fixedly connected w...

Embodiment 3

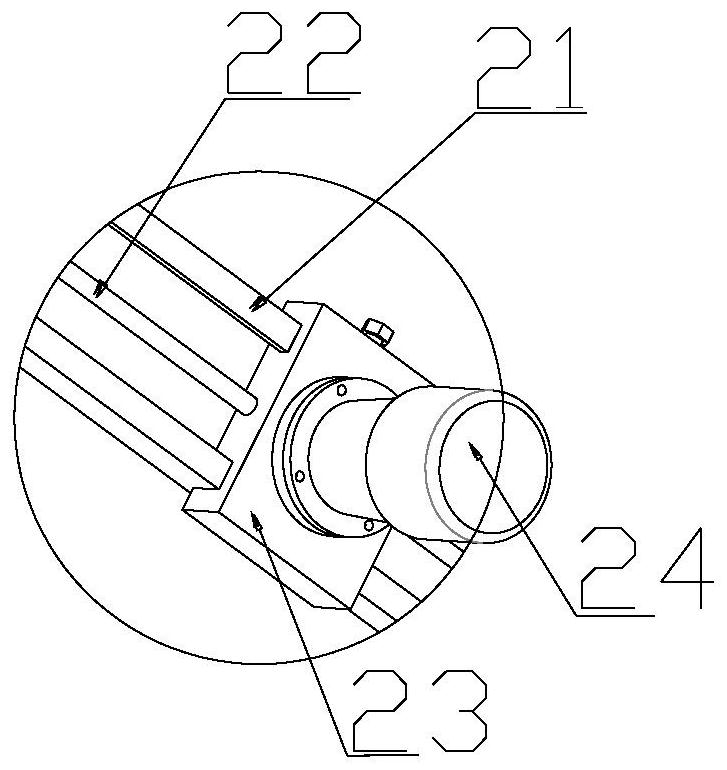

[0055] see Figure 9 , the present embodiment is used for asphalt mixing device, on the basis of embodiment 2, its gear transmission assembly 404 includes forward rotation gear 4041, fixed frame 4042, steering adjustment gear 4043 and reverse rotation gear 4044, fixed frame 4042 It is a rectangular frame structure. The forward rotation gear 4041, the steering adjustment gear 4043 and the reverse rotation gear 4044 are all placed in the frame of the fixed frame 4042. The forward rotation shaft 403 runs through the fixed frame 4042 and is fixed with the forward rotation gear 4041. connection, the forward rotation shaft 403 is rotatably connected with the frame wall of the fixed frame 4042 through bearings, the forward rotation gear 4041 meshes with the steering adjustment gear 4043, the steering adjustment gear 4043 meshes with the reverse rotation gear 4044, and the reverse rotation gear 4044 meshes with the wear The reverse rotation sleeve 405 on one side of the fixed frame 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com