Upper clamping claw device of textile equipment

A technology of textile equipment and grippers, which is applied in the field of textile automation equipment, can solve problems such as lengthened production cycle, increased equipment load, and low production efficiency, and achieve the effects of large movement range of grippers, precise torque control, and accurate and fast grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

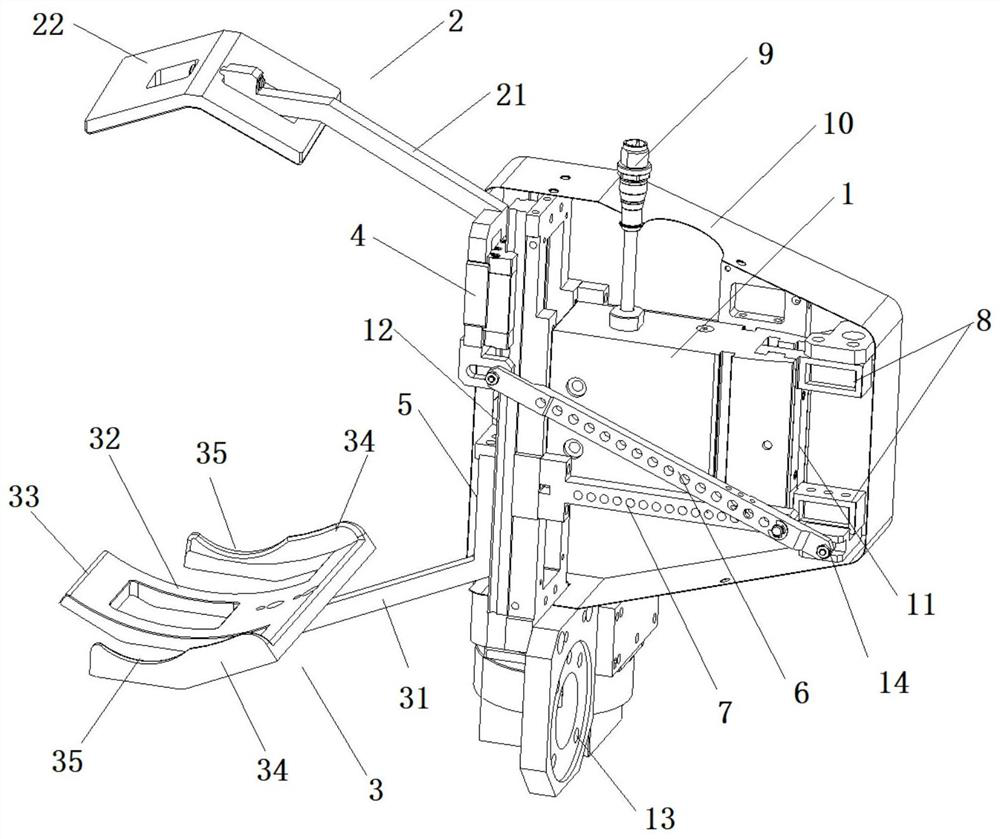

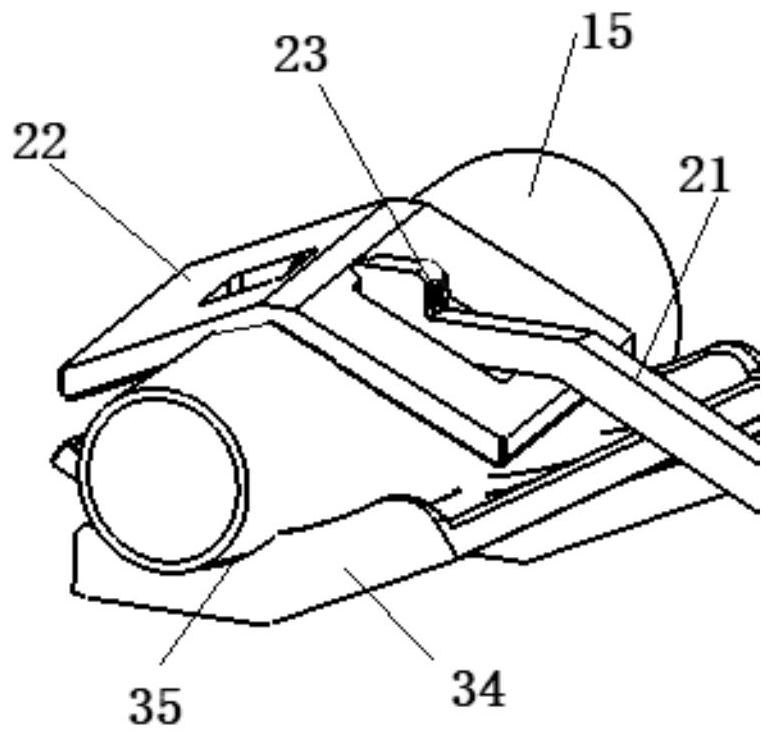

[0018] like Figure 1-Figure 3 The upper jaw device of the textile equipment shown in the present invention includes an upper jaw 2 and a lower jaw 3 that are driven by a torque drive device to move relative to each other. In this embodiment, the upper jaw 2 and the lower jaw 3. Metal materials are preferably used, and hard plastic materials can be used according to the needs of the use environment. The lower clamping jaw 3 includes a lower clamping plate 32 provided with three claws, and the two side claws 34 of the lower clamping plate 32 are symmetrically arranged. The positioning groove 35, the present invention is aimed at the difference between the bobbin 15 and the spindle shape, and the lower clamping plate 32 of the lower three jaws is set, and the upper clamping jaw 2 includes an upper clamping plate 22, and the upper clamping plate 22 is located on the lower clamping plate when clamping 32 between the two side claws 34 and covered on the middle claw 33 of the lower ...

Embodiment 2

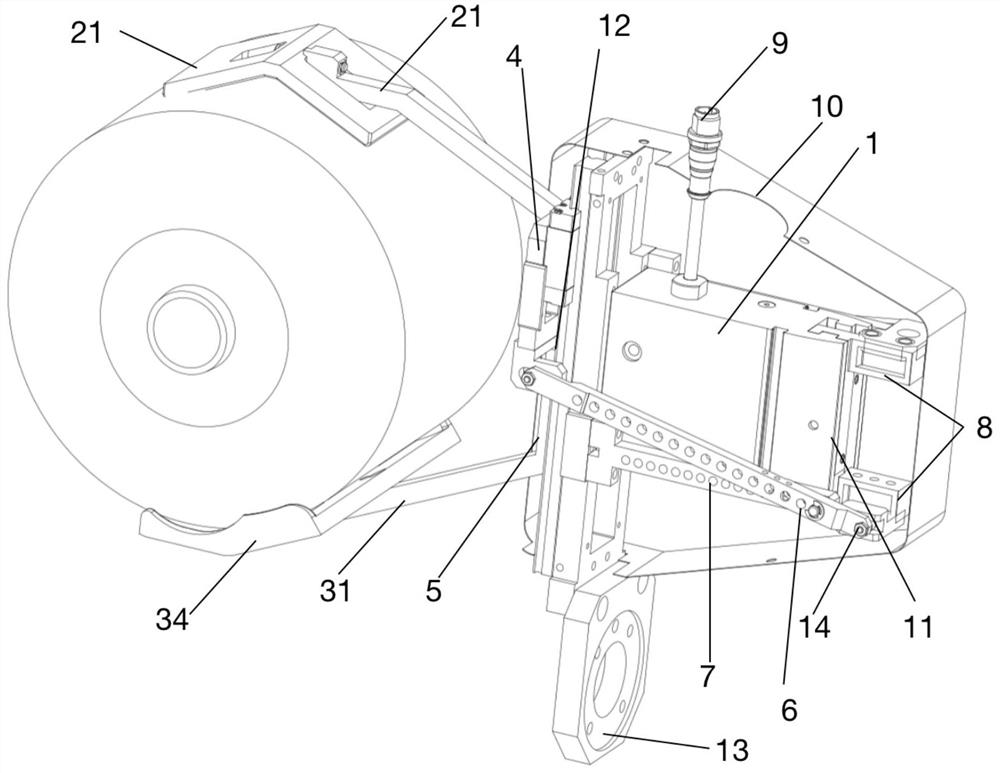

[0023] On the basis of Embodiment 1, the torque drive device includes a drive motor, the drive motor preferably adopts a servo motor, which can output torque more accurately, and the upper jaw 2 and the lower jaw 3 pass through the upper slider 4 and the lower jaw respectively. The slider 5 is arranged on the track 12, and the upper slider 4 and the lower slider 5 can slide up and down along the track 12, and the upper slider 4 and the lower slider 5 are respectively connected to the upper link 6 and the lower link. A drive motor, the drive motor drives the upper link 6 and the lower link to drive the upper slider 4 and the lower slider 5 to move up and down, thereby driving the upper jaw 2 and the lower jaw 3 to achieve clamping. In the present invention , the upper link 6 and the lower link move synchronously, and after the movement, the upper and lower sliders 5 are driven to move at the same time. When sliding to both ends, the upper jaw 2 and the lower jaw 3 are separated....

Embodiment 3

[0028] On the basis of the above embodiments, the drive motor is a servo motor, and the servo motor is connected to the cam linkage arranged in the drive chute 11, and the ends of the upper link 6 and the lower link are respectively connected to the The drive slider 8 in the drive chute 11 is connected, and the servo motor drives the drive slider 8 to move up and down through the cam linkage mechanism. It forms a multi-stage connecting rod with the upper and lower struts 31, and produces the largest movement stroke with the smallest volume.

[0029] In this embodiment, the upper link 6 and the lower link are respectively rotatably connected to the drive slider 8 through a cam follower 14, and are rotatably connected to the drive slider 8 through a cam follower 14. Motion trails are smaller.

[0030]In this embodiment, the torque driving device is connected with a signal receiving device 9, and the torque driving device adjusts the torque through the signal received by the sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com