Self-adaptive automatic balance circulating cooling system

A circulating cooling system and automatic balancing technology, which is applied in the field of self-adaptive automatic balancing circulating cooling system, can solve problems such as increased wear of dynamic and static connecting parts, complex cooling system composition, and easy damage to the surface of the strip roller, so as to improve production quality and efficiency , The overall structure is simple and the dynamic sealing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to better understand the technical solutions of the present invention, the present invention is now clearly and completely described through embodiments in conjunction with the accompanying drawings.

[0010] The tape spraying device of the present invention implements tape spraying and tape making in a dynamic tape spraying manner through a moving tape throwing roller relative to the nozzle.

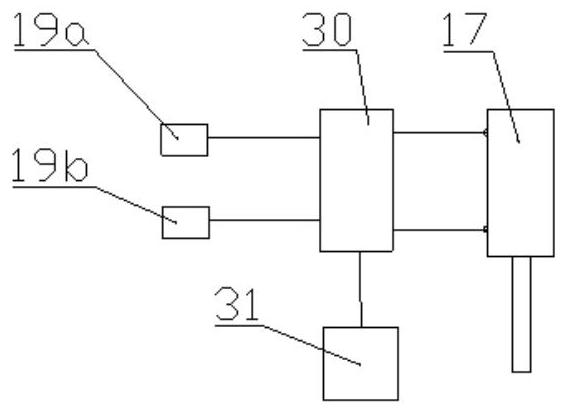

[0011] like figure 1 shown. The self-adaptive self-balancing circulating cooling system of the present invention includes a dynamic sealing connection device 22, a cooling inner chamber 21 arranged in the strip roller, and the inner chamber of the hollow shaft 19 connected to the sliding frame 50 through a corresponding bearing device. The strip roller 20 is fixedly connected to the hollow shaft. The cooling inner cavity of the strip roller is provided with a guide inner cylinder 23 connected to the hollow shaft. The dynamic sealing connection 22 comprises a rotary jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com