Dust cleaning equipment for constructional engineering

A technology for construction engineering and cleaning equipment, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve problems such as excessive dust, and achieve the effect of ensuring cleaning effect and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

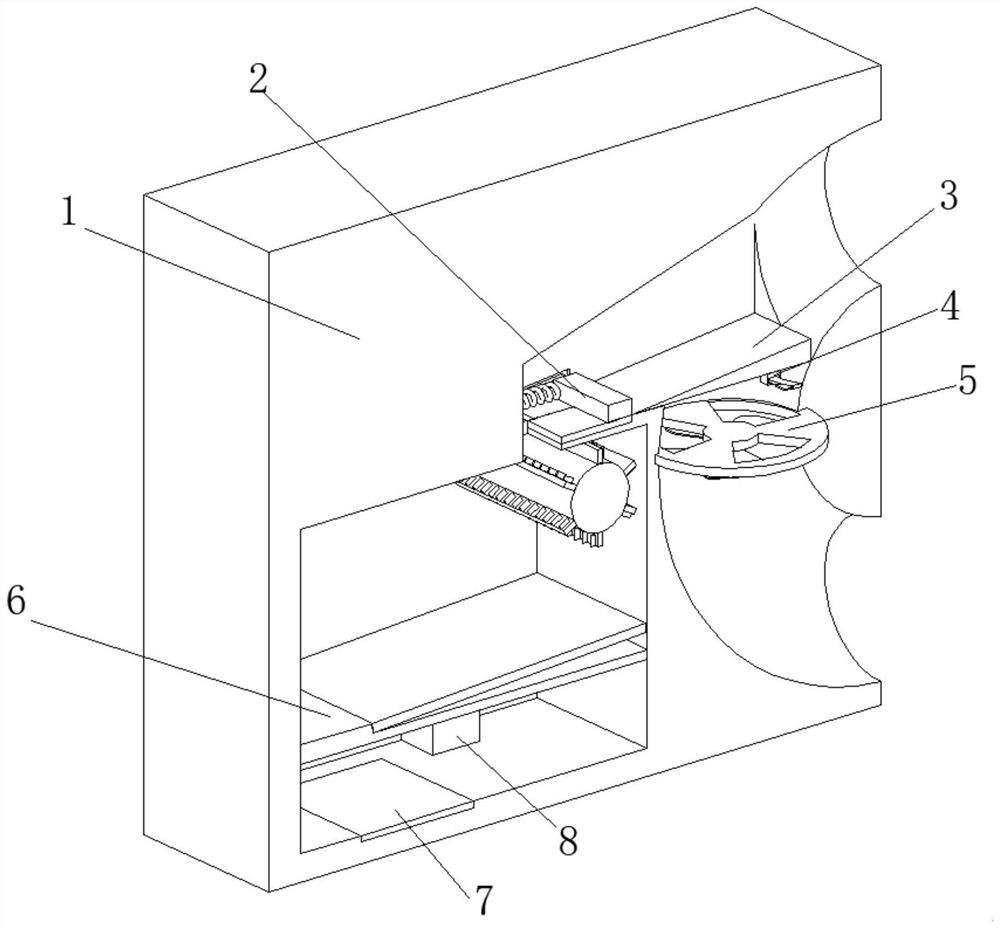

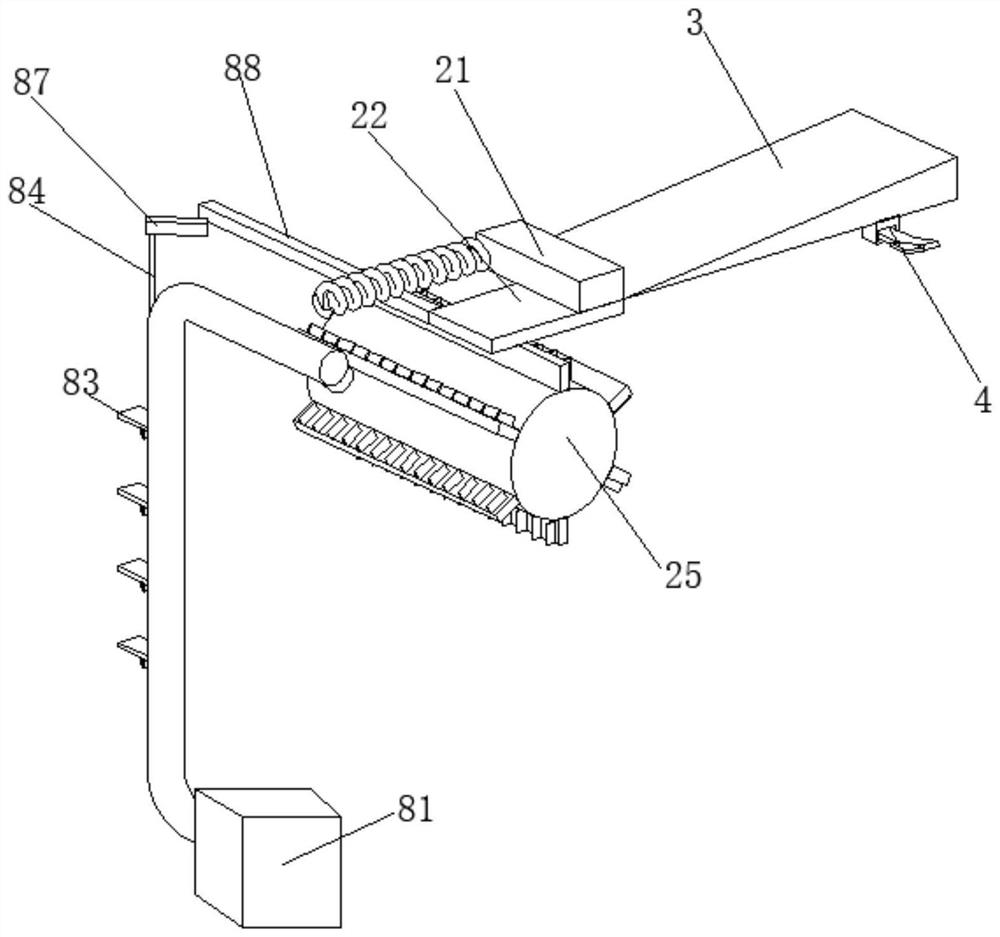

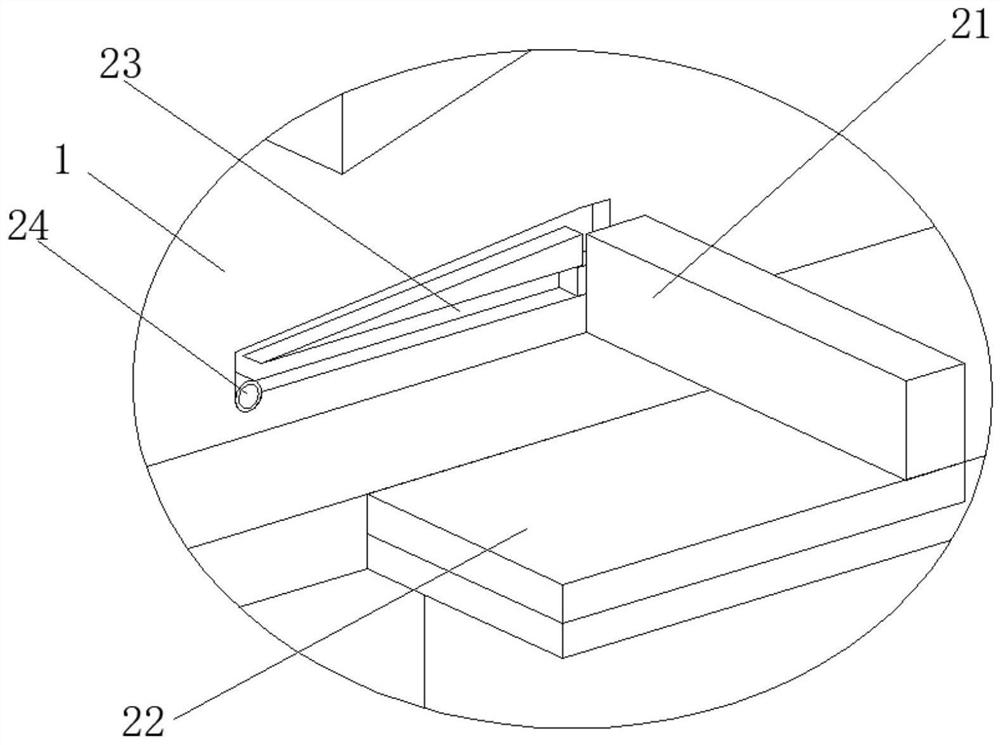

[0030] A construction dust cleaning device, such as Figure 1-Figure 9 As shown, the box body 1 is included, the inside of the box body 1 is provided with a collection mechanism 2, the inner wall of the box body 1 is fixedly connected with a filter screen 3, the bottom of the filter screen 3 is welded with a fixed block 4, and the inner wall of the fixed block 4 is movably connected with a Arc-shaped plate 41, the surface of arc-shaped plate 41 is welded with guide plate 42, the inner wall of box body 1 is fixedly connected with fan group 5, the inner wall of box body 1 is provided with discharge mechanism 6, and the bottom wall inside box body 1 is fixedly connected There is a soap bar 7, the inner wall of the box body 1 is provided with a dust reduction mechanism 8, the discharge mechanism 6 includes a filter plate 61, the inner wall of the filter plate 61 is rotatably connected with a rotating plate 62, and the surface of the filter plate 61 is fixedly connected with an elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com