An explosion-proof stepping motor

A stepping motor and main body technology, applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of large dust accumulation, inability to open holes for heat dissipation, and certain requirements for the airtightness of the motor main body, so as to achieve sufficient guarantee The effect of using, ensuring the service life and avoiding frequent disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

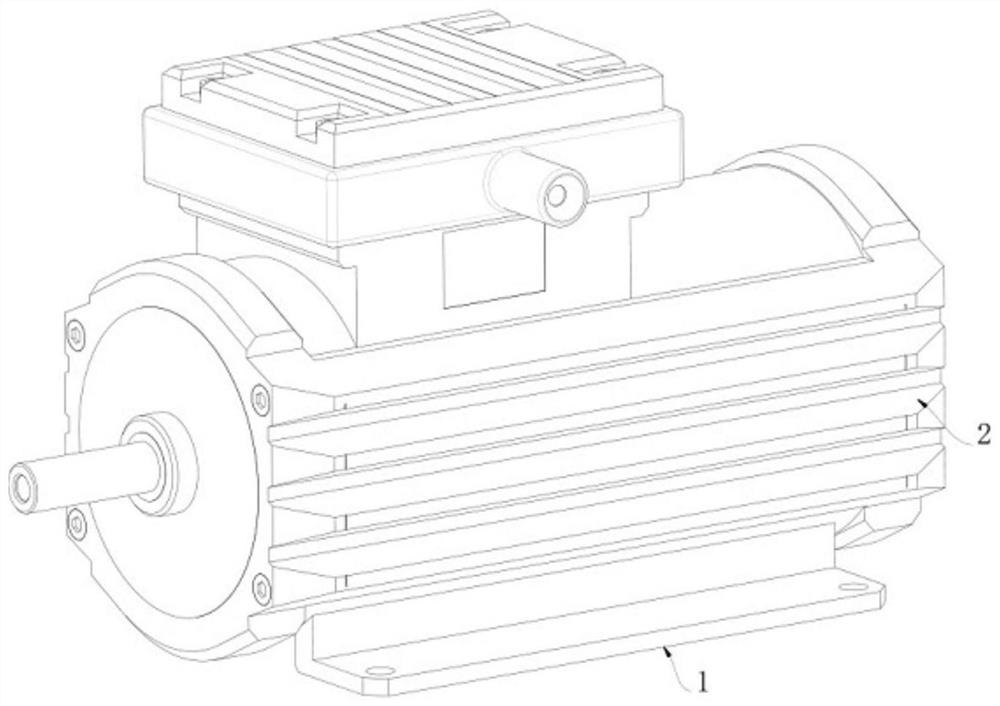

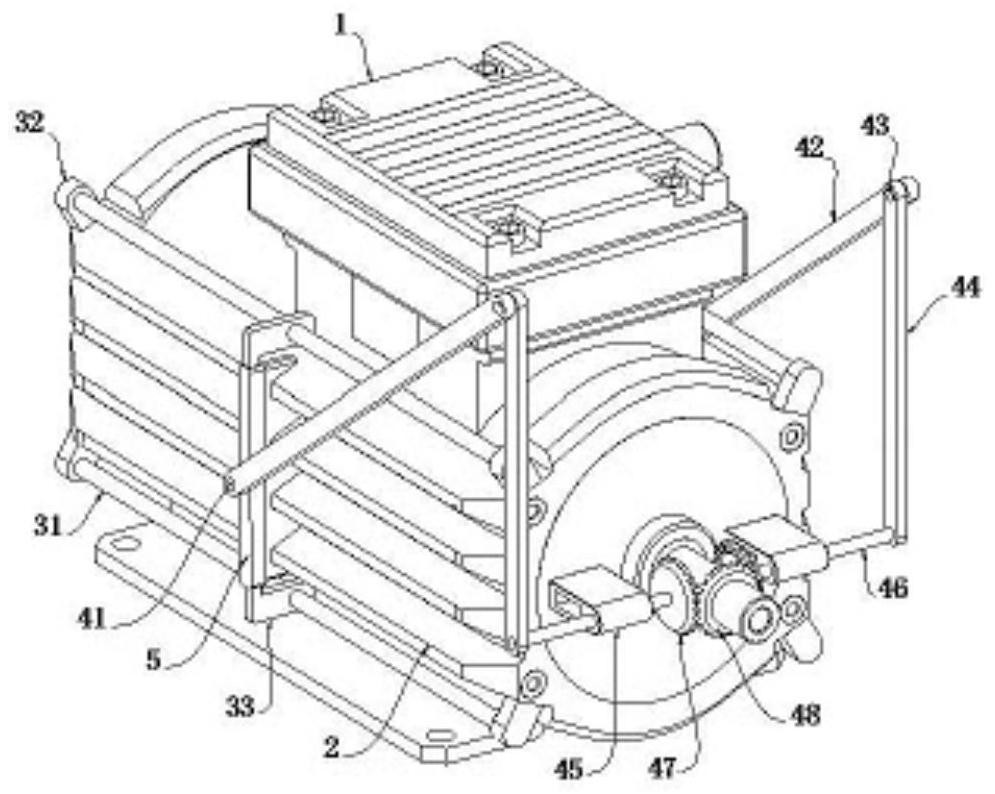

[0032] see Figure 1-5 , The present invention provides a technical solution: an explosion-proof stepping motor, comprising a motor body 1 and a heat dissipation fin 2, and a cleaning component 3 is arranged on the outside of the motor body 1;

[0033] The cleaning member 3 includes a plurality of guide rods 31, the plurality of guide rods 31 are respectively located at the side of the motor body 1, and a bearing seat 32 is provided at the end of each guide rod 31, and the bearing seat 32 is installed on the motor. On the main body 1 , the cleaning member 3 further includes a sliding seat 33 respectively arranged on each guide rod 31 , and a brush plate 5 is arranged at the position of the heat dissipation fins 2 on the side of the motor main body 1 , and the brush plate 5 is installed On the sliding seat 33, it is in contact with the surface of the cooling fins 2, and is connected with the linking part 4. Further, the brush plate 5 is detachably connected with the sliding sea...

Embodiment 2

[0041] see Figure 6-8 , The present invention provides a technical solution: an explosion-proof stepping motor, comprising a motor body 1 and a heat dissipation fin 2, and a cleaning component 3 is arranged on the outside of the motor body 1;

[0042] The cleaning component 3 includes a plurality of cleaning brush rollers 61 respectively arranged between the gaps of the heat dissipation fins 2, the cleaning brush rollers 61 are in contact with the surface of the heat dissipation fins 2, and both ends of the cleaning brush roller 61 are rotatably installed with bearing seats 62, and The bearing bases 62 are installed on the motor main body 1, and a transmission gear 63 is provided at one end of each cleaning brush roller 61 away from the output shaft of the motor main body 1, and adjacent transmission gears 63 are engaged with each other;

[0043] The end of the motor body 1 is provided with a linking member 4, the linking member 4 includes a main drive gear 71 arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com