Assembling system capable of automatically calibrating precision

An assembly system and automatic calibration technology, which is applied in metal processing, manipulators, metal processing equipment, etc., can solve problems such as low automation, low installation accuracy, and high labor costs, so as to avoid safety accidents, improve automation, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

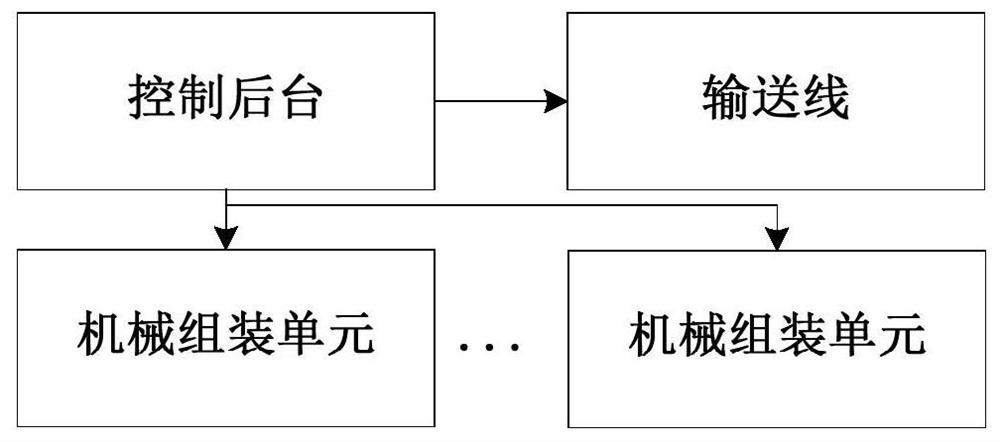

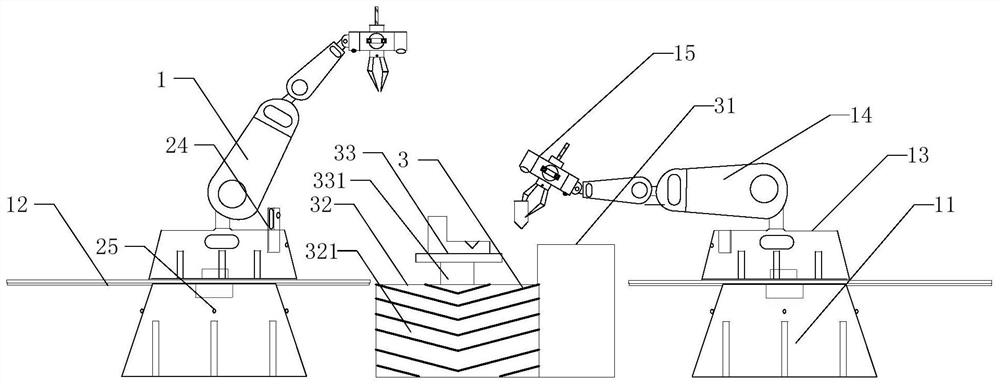

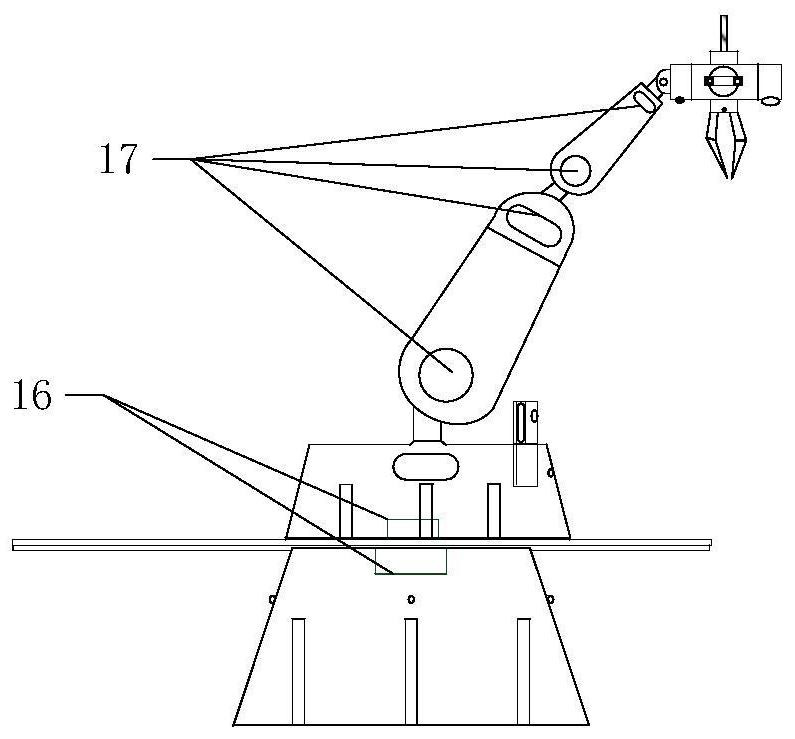

[0030] This embodiment provides as figure 1 and figure 2 Commonly shown, this embodiment provides an assembly system for automatic calibration accuracy, including a conveyor line 3, a control background, and several mechanical assembly units. It is arranged close to the conveying line 3, and each mechanical assembly unit grabs a mechanical part, and the top surface of the conveying line 3 is placed with a mechanical main body, and the mechanical part and the mechanical main body are combined to form a mechanical device;

[0031] The mechanical assembly unit receives the control signal from the control background, assembles the captured mechanical parts to the mechanical body on the conveyor line 3, and collects the posture information of the mechanical parts in real time to automatically calibrate the assembly accuracy, and adjusts the equipment in the mechanical assembly unit in real time The conveying line 3 fixes and transports the mechanical body to the mechanical assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com