DC bus pre-charging system

A pre-charging, bus circuit technology, applied in control systems, electrical components, AC motor control, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

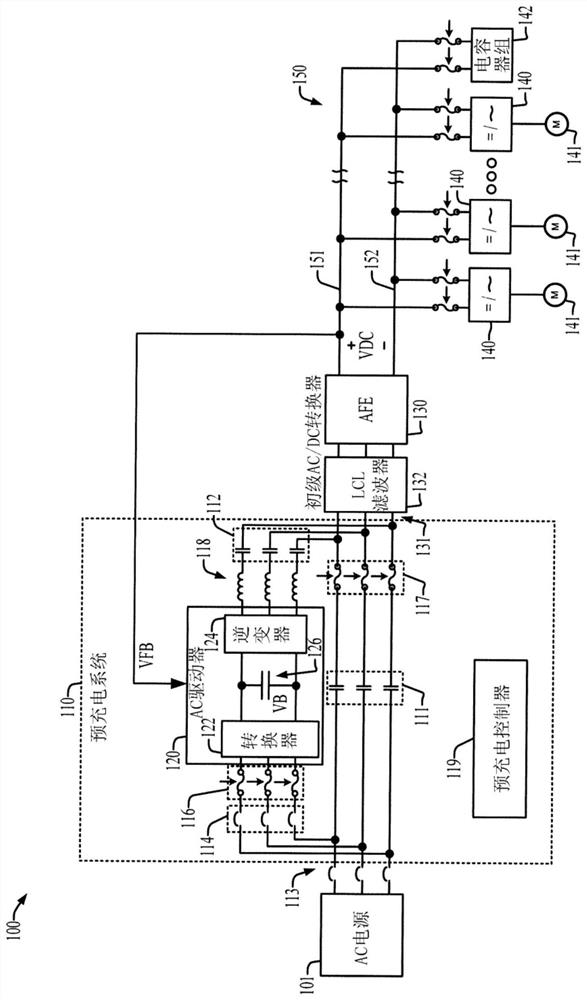

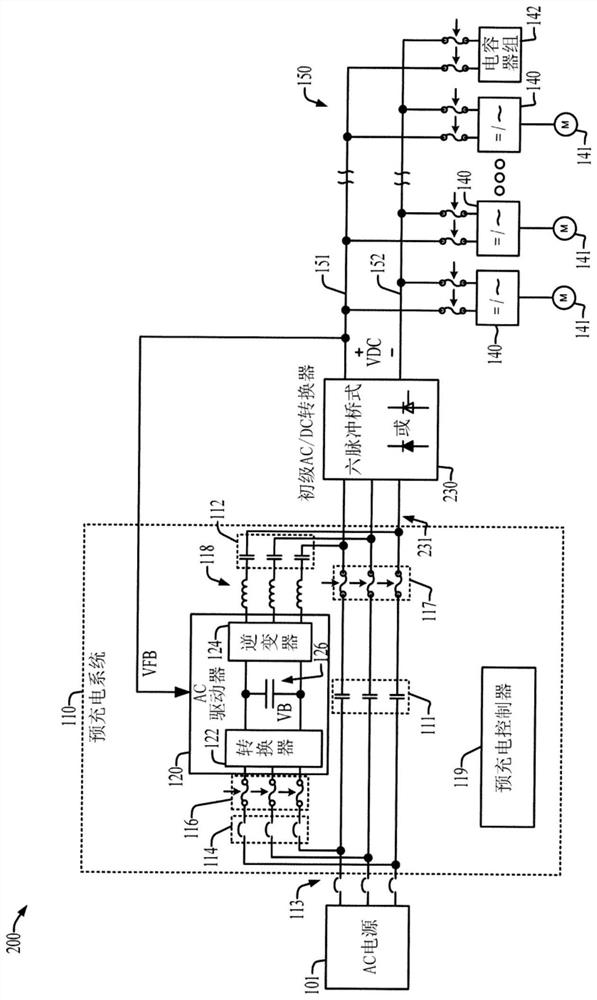

[0013] Power conversion systems typically use a shared DC bus architecture in which multiple DC loads are connected to a single bus. For example, a shared bus system may accommodate multiple inverters and one or more capacitor banks to power respective motors. High capacity systems with high power requirements may include large DC bus capacitors designed to operate at relatively high DC voltages. When starting up such a system, one or more DC bus capacitors need to be charged to a sufficient voltage for safe operation of the connected inverter or other DC load. However, simply connecting to an input voltage source to charge a capacitive load can result in excessive inrush current levels. In this regard, for example, when certain loads are disabled and / or disconnected from the shared bus, the amount of load and bus capacitance may vary. On the other hand, limiting the charge current prolongs the precharge time. Long pre-charge / start-up times are undesirable for industrial in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com