A vertical cable laying support and fixing device for wind power generation

A fixing device and vertical cable technology, applied in the direction of cable laying equipment, etc., can solve the problems of difficult cable laying direction, cumbersome process, and high use limitations, and achieve cable clamping and fixing labor-saving, ensure stability, and increase friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

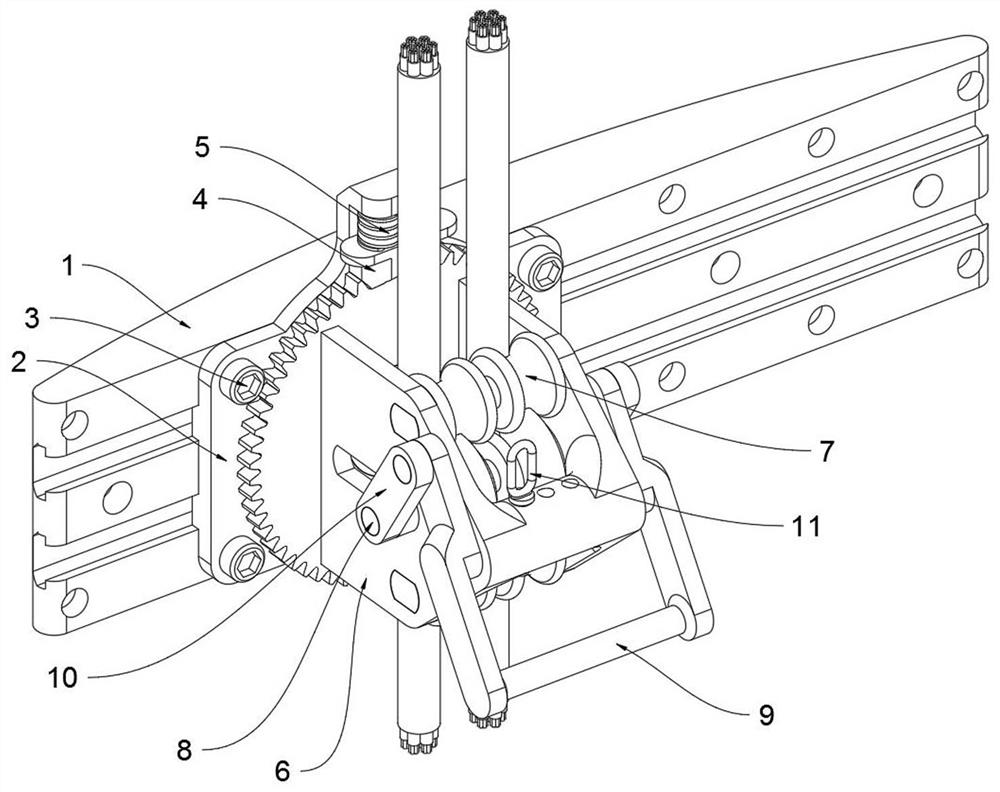

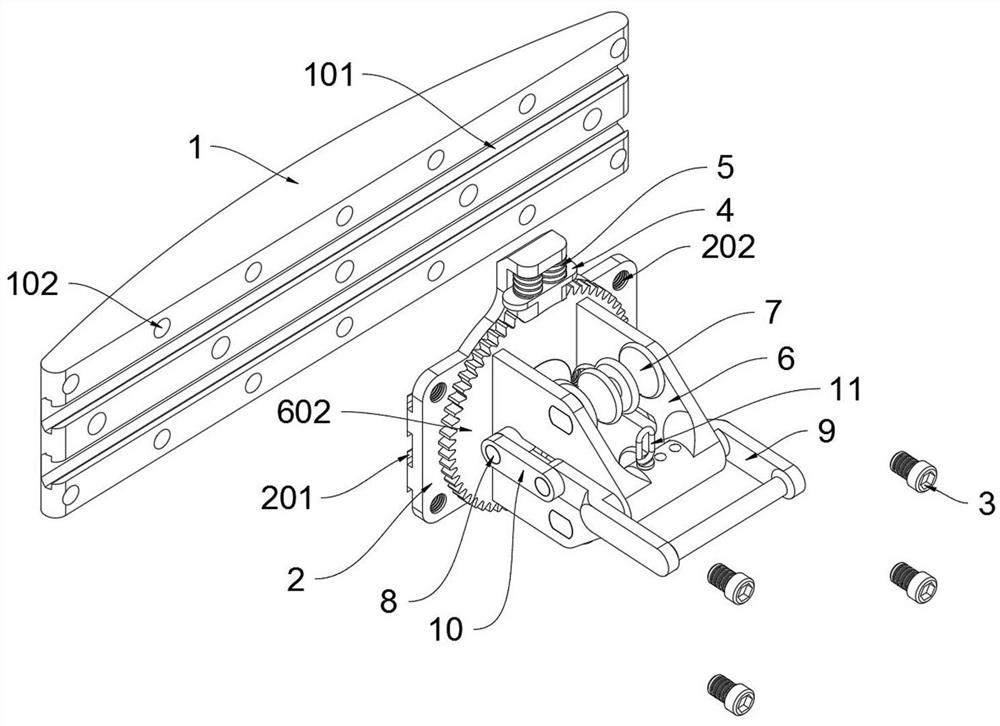

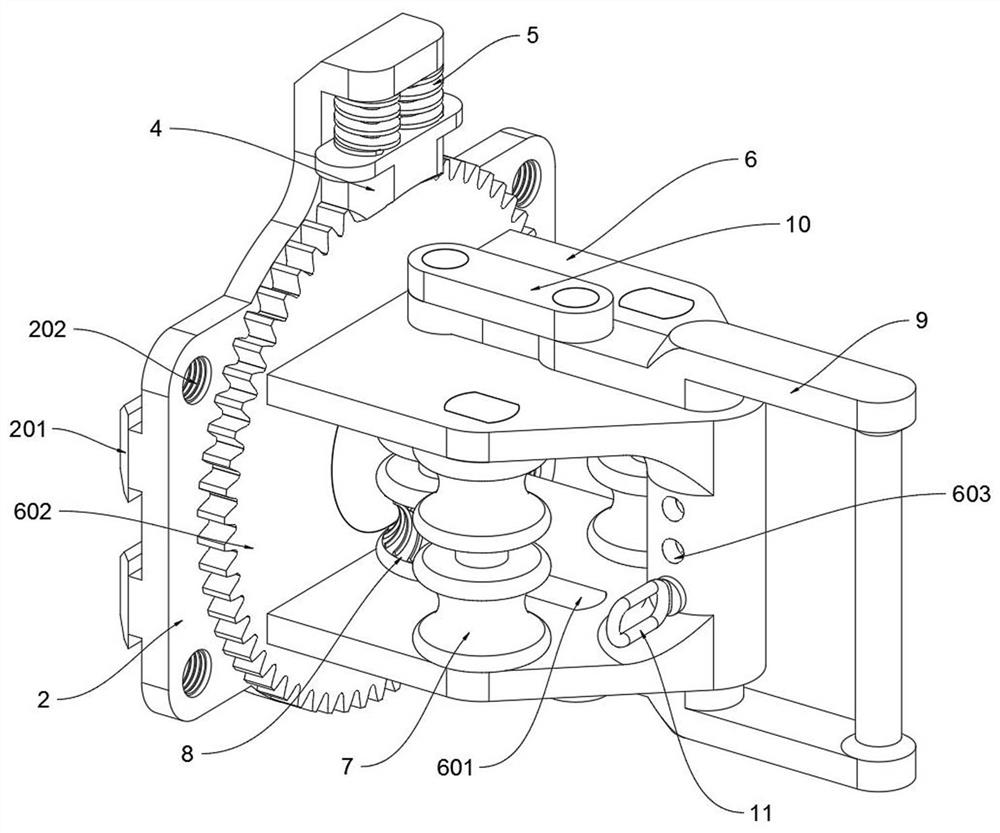

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The invention provides a vertical cable laying support and fixing device for wind power generation, which includes an assembly base 1 and a tooth block 4;

[0037] The front side of the assembly base 1 is connected with a movable seat 2, and the front side of the movable seat 2 is connected with the support seat 6; the tooth block 4 is connected with the top of the front side of the movable seat 2, and the bottom end of the tooth block 4 is connected with the top end of the support seat 6; the support seat 6 is internally connected with a movable clamping rod 8, and the two ends of the movable clamping rod 8 are respectively connected with the driving frame 9 through the connecting rod 10, and the driving frame 9 is fixedly connected with the support seat 6 through the locking pin 11; the left and right sides of the support seat 6 are respectively provided with Sliding hole 601, the inside of the support seat 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com