Mixing method based on floating mortar for buildings

A construction and floating construction technology, applied in chemical instruments and methods, clay preparation equipment, cement mixing equipment, etc., can solve the problems of material cracking, inconvenient cleaning, poor mixing effect, etc., achieve good crack resistance and save power resources , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

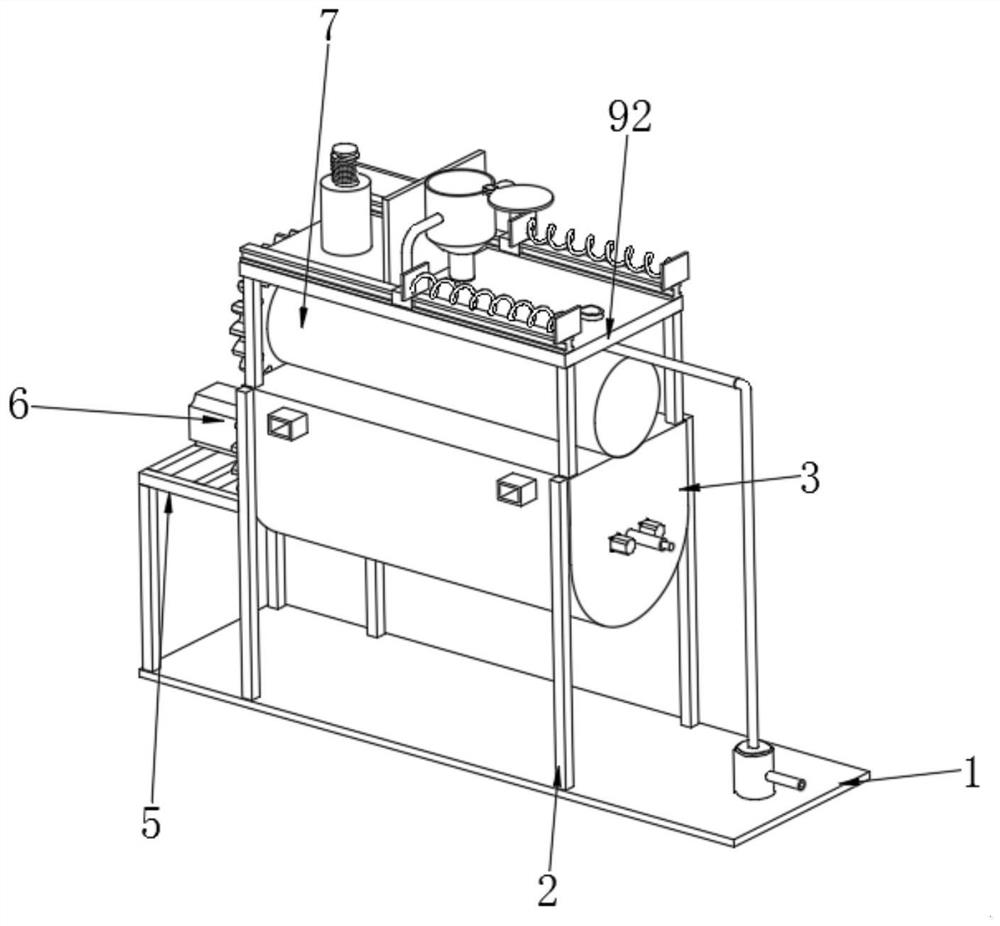

Image

Examples

Embodiment 1

[0037] Specifically include the following steps:

[0038] Step 1. Proportion of floating mortar: the raw materials are divided by mass percentage: 10% ordinary silicon cement, 2% sulfur-aluminum cement, 3% micro-expansion factor, 15% filler, aggregate leveling, 1% leveling agent, 1% thickening agent, 1% compacting agent, 0.5% setting retarder and 1% anti-cracking agent;

[0039] Step 2. Mixing of main materials: Put ordinary silicate cement, sulfur-aluminum cement, micro-expansion factor, filler and aggregate into the mixing equipment in sequence according to mass percentage, and under the action of the mixing equipment, ordinary silicate cement, sulfur-aluminum cement, Stir the micro-expansion factor, filler and aggregate at 250r / min for 10min until uniform;

[0040] Step 3, additive mixing: At this time, add leveling agent, thickener, compacting agent, retarder and anti-cracking agent to the mixing equipment in step 2 in sequence, increase the speed to 500r / min and continue...

Embodiment 2

[0045] Specifically include the following steps:

[0046] Step 1. Proportion of floating construction mortar: the raw materials include: ordinary silicon cement 15%, sulfur-aluminum cement 5%, micro-expansion factor 3%, filler 20%, aggregate leveling, leveling agent 3%, 2% thickening agent, 2% compacting agent, 1% setting retarder and 2% anti-cracking agent;

[0047] Step 2. Mixing of main materials: Put ordinary silicate cement, sulfur-aluminum cement, micro-expansion factor, filler and aggregate into the mixing equipment in sequence according to mass percentage, and under the action of the mixing equipment, ordinary silicate cement, sulfur-aluminum cement, Stir the micro-expansion factor, filler and aggregate at 350r / min for 10min until uniform;

[0048] Step 3, additive mixing: At this time, add leveling agent, thickener, compacting agent, retarder and anti-cracking agent to the mixing equipment in step 2 in sequence, increase the speed to 600r / min and continue stirring fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com