Ceramic processing equipment for sewage treatment in hour hand simulation waste residue collection

A technology for sewage treatment and ceramic processing, applied in ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of reducing energy saving, reducing energy reproduction, and easily scratching and damaging ceramic utensils by waste residues. The effect of improving the quality of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

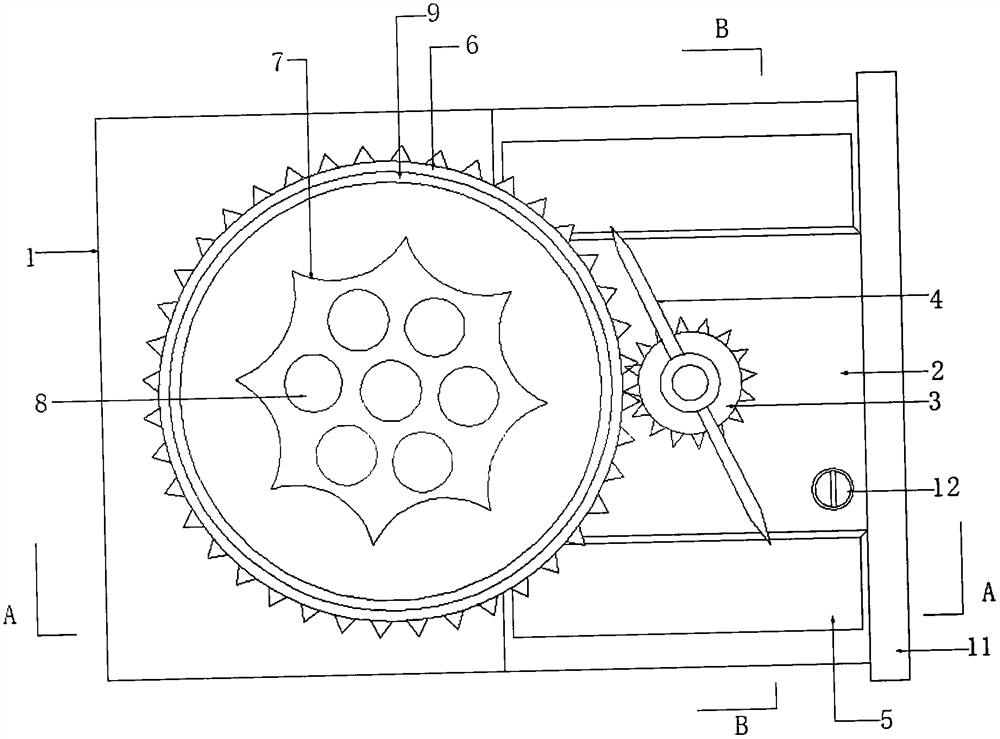

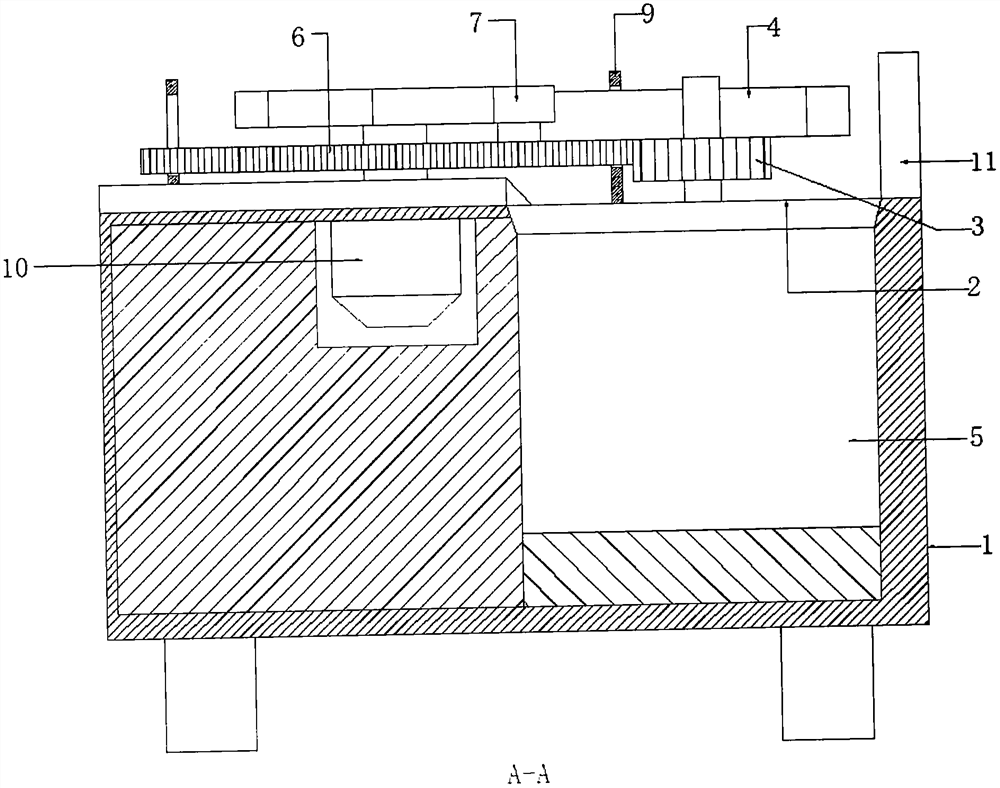

[0035] Such as Figure 1-2 displayed in:

[0036] The present invention provides a kind of ceramic processing equipment for sewage treatment in clock simulation waste slag collection, comprising a working box 1, both ends of the bottom of the working box 1 are provided with supporting feet, and one side of the top of the working box 1 is provided with a concave surface 2, wherein, the top center of the concave surface 2 is provided with a gear one 3, the middle part of the gear one 3 is interspersed with a gear shaft, and the bottom of the gear shaft is movably connected to the corresponding position on the top of the working box 1 , the top of the gear shaft is provided with a scraper 4, both sides of the concave surface 2 and both ends of one side in the working box 1 are provided with a waste residue treatment bin 5 with an opening at the top, and the top of the working box 1 is And near the center of one side of the concave surface 2 is provided with a gear two 6 meshed wit...

Embodiment 2

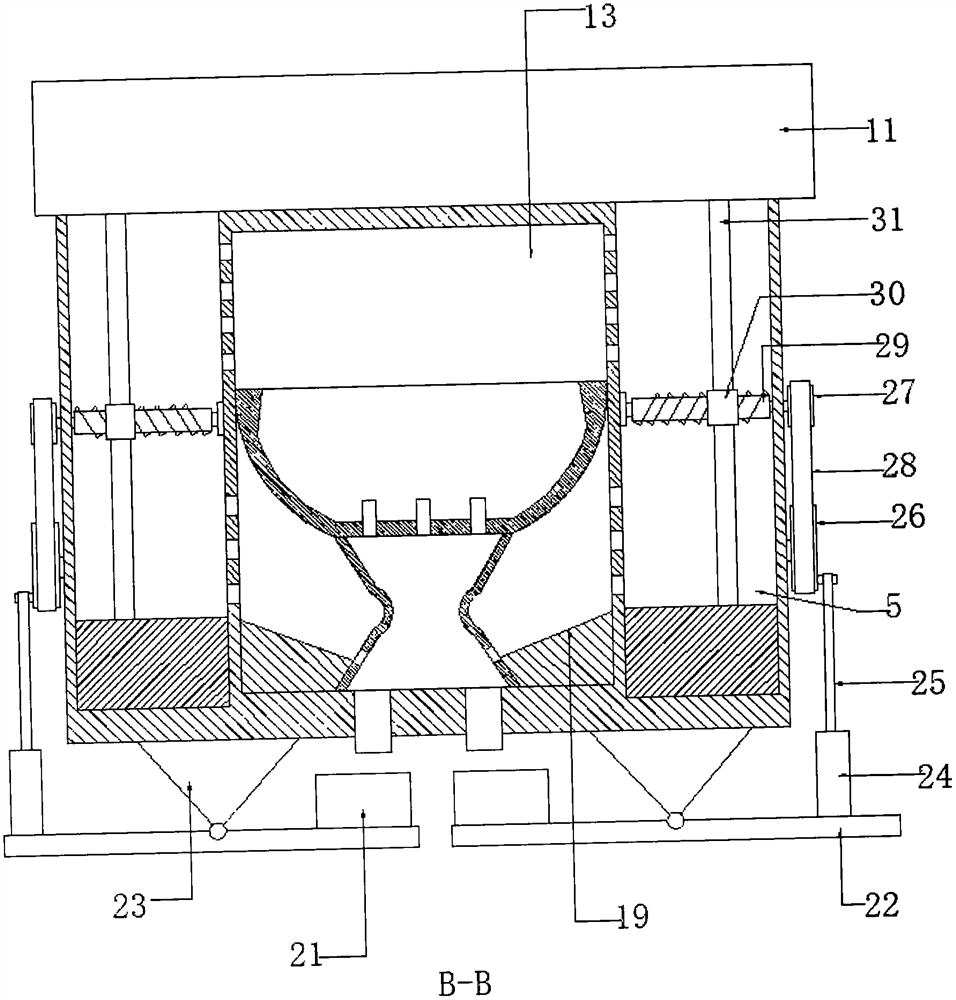

[0039] Such as figure 1 with Figure 3-5 displayed in:

[0040] The present invention provides a kind of ceramic processing equipment for sewage treatment in clock simulation waste slag collection, comprising a working box 1, both ends of the bottom of the working box 1 are provided with supporting feet, and one side of the top of the working box 1 is provided with a concave surface 2, wherein, the top center of the concave surface 2 is provided with a gear one 3, the middle part of the gear one 3 is interspersed with a gear shaft, and the bottom of the gear shaft is movably connected to the corresponding position on the top of the working box 1 , the top of the gear shaft is provided with a scraper 4, both sides of the concave surface 2 and both ends of one side in the working box 1 are provided with a waste residue treatment bin 5 with an opening at the top, and the top of the working box 1 is And near the center of one side of the concave surface 2 is provided with a gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com