A nozzle orientation vector control structure

A nozzle and vector technology, which is applied in the field of nozzle azimuth vector control structure, can solve the problems that the spray direction is not easy to change, and the spray direction cannot be automatically calibrated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

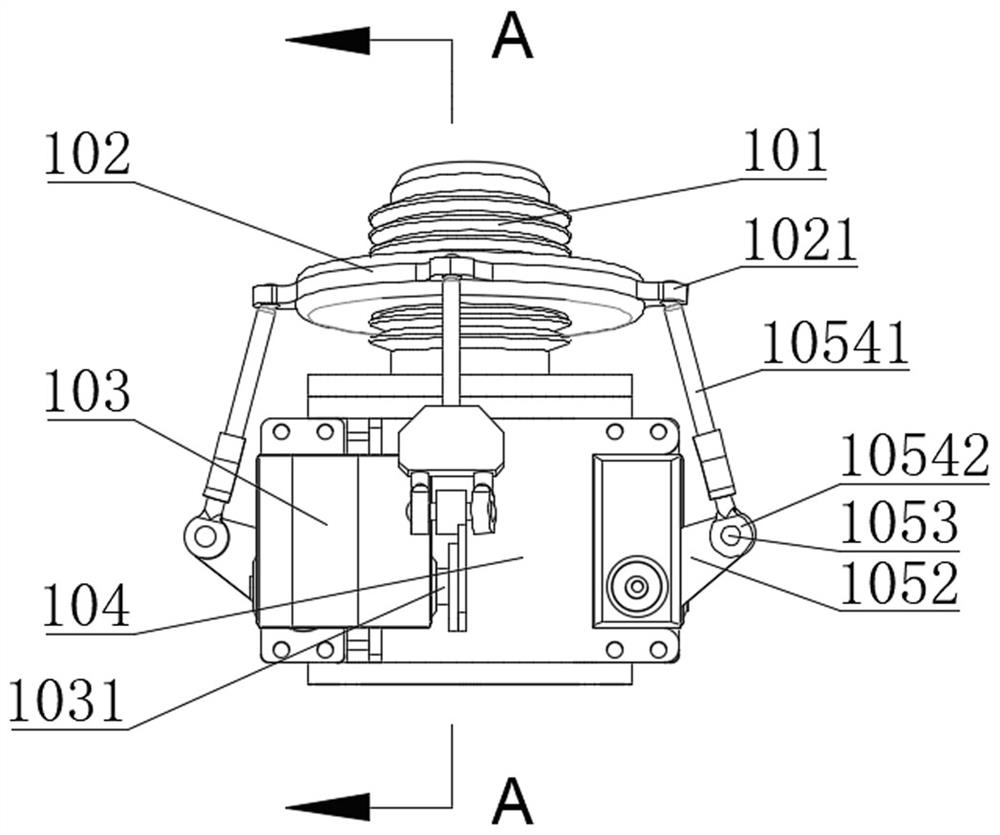

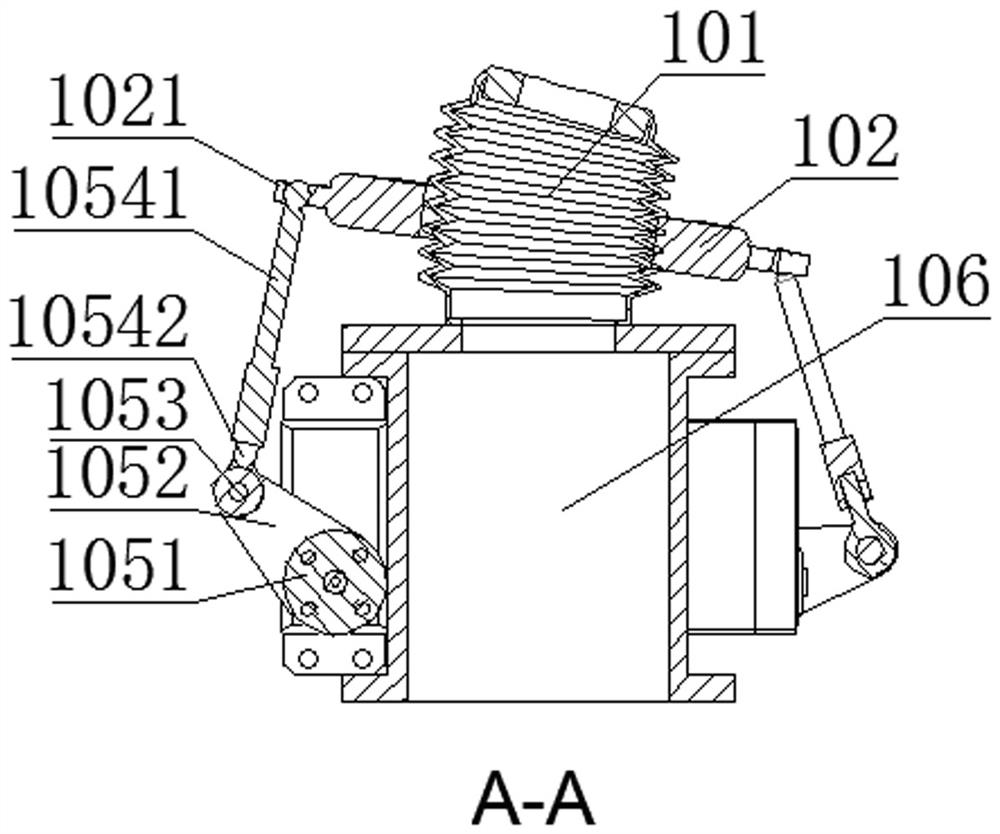

[0020] Such as Figure 1-4 As shown, a nozzle orientation vector control structure includes a corrugated nozzle 101 , an amplitude modulation ring 102 , four steering gears 103 and a steering gear mounting seat 104 .

[0021] The circumference of the amplitude modulation ring 102 is integrally provided with four evenly arranged amplitude modulation ring connecting ears 1021 , and the amplitude modulation ring connecting ears 1021 are respectively connected to one steering gear 103 through a crank linkage mechanism 105 .

[0022] The inner ring of the amplitude modulation ring 102 is clamped on the middle section of the corrugated nozzle 101 . One end of the corrugated nozzle 101 is fixed, and the gas is ejected from the other end of the corrugated nozzle 101 .

[0023] The steering gear mounting base 104 is fixedly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com