Rolling spraying machine, intelligent air control method thereof, device and storage medium

A rolling spraying and intelligent technology, applied in spraying device, device for coating liquid on surface, surface pretreatment, etc., can solve the problems of uneven paint thickness, difficult drying of paint, poor quality of finished materials, etc. Consistent, speed-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

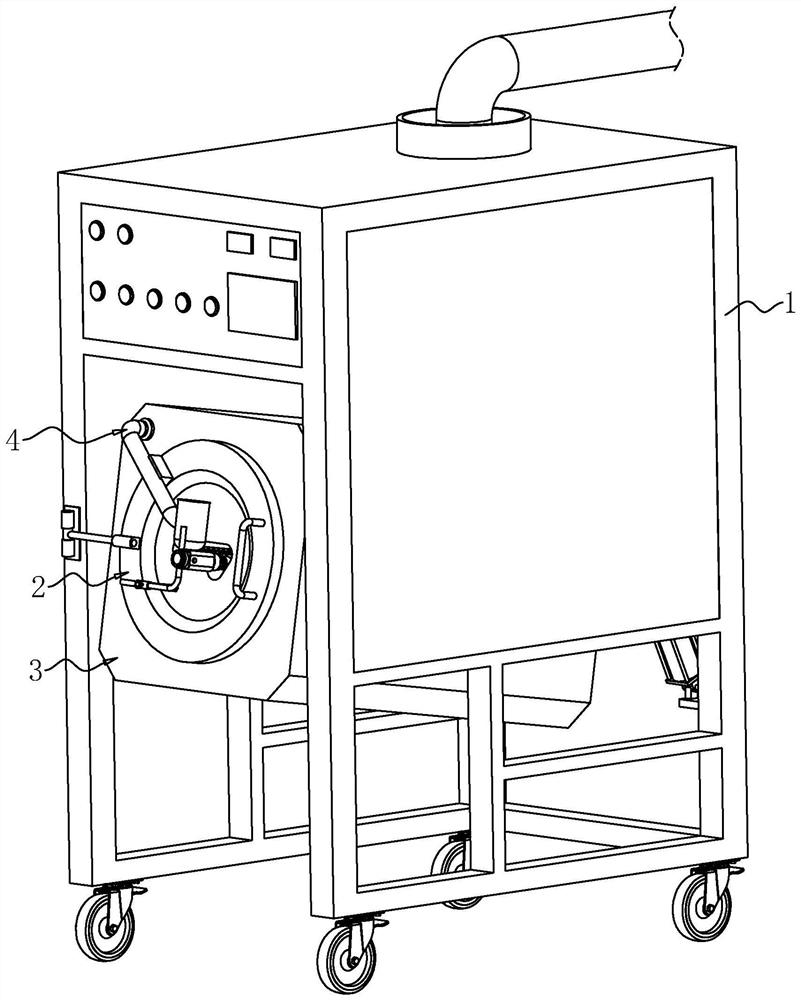

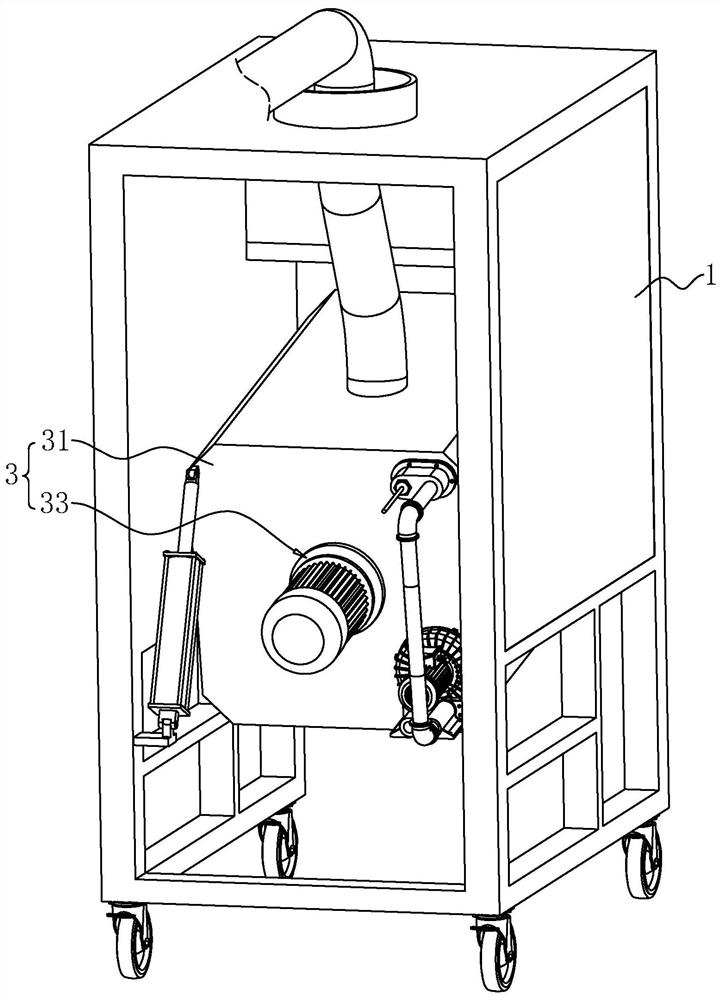

[0060] Refer figure 1 with figure 2 A spraying machine comprising a roller frame 1, 2 and stacker paint component assembly 3; 2 wherein the spray assembly rotatably connected to the frame 1 for aqueous paint to spray the internal stacker assembly 3, which form the axis of rotation vertically disposed, paint component 2 can be moved in a direction toward or away from the shuttle assembly 3 stacker; stacker assembly 3 rotatably connected to the frame 1 for turning the material for spray painting assembly 2, its axis of rotation disposed horizontally; 2 is also mounted on the spray assembly may be a hot air blowing hot air assembly 4; spray direction of the wind direction component hot spray assembly 4 is provided with 2 to the form.

[0061] When the spray dryer roll in use, to turn the entire assembly of the rotation axis 3 and obliquely upward angle appropriate position, turned away from the paint feed assembly 2 toward the moving direction of the assembly 3, the material turned i...

Embodiment 2

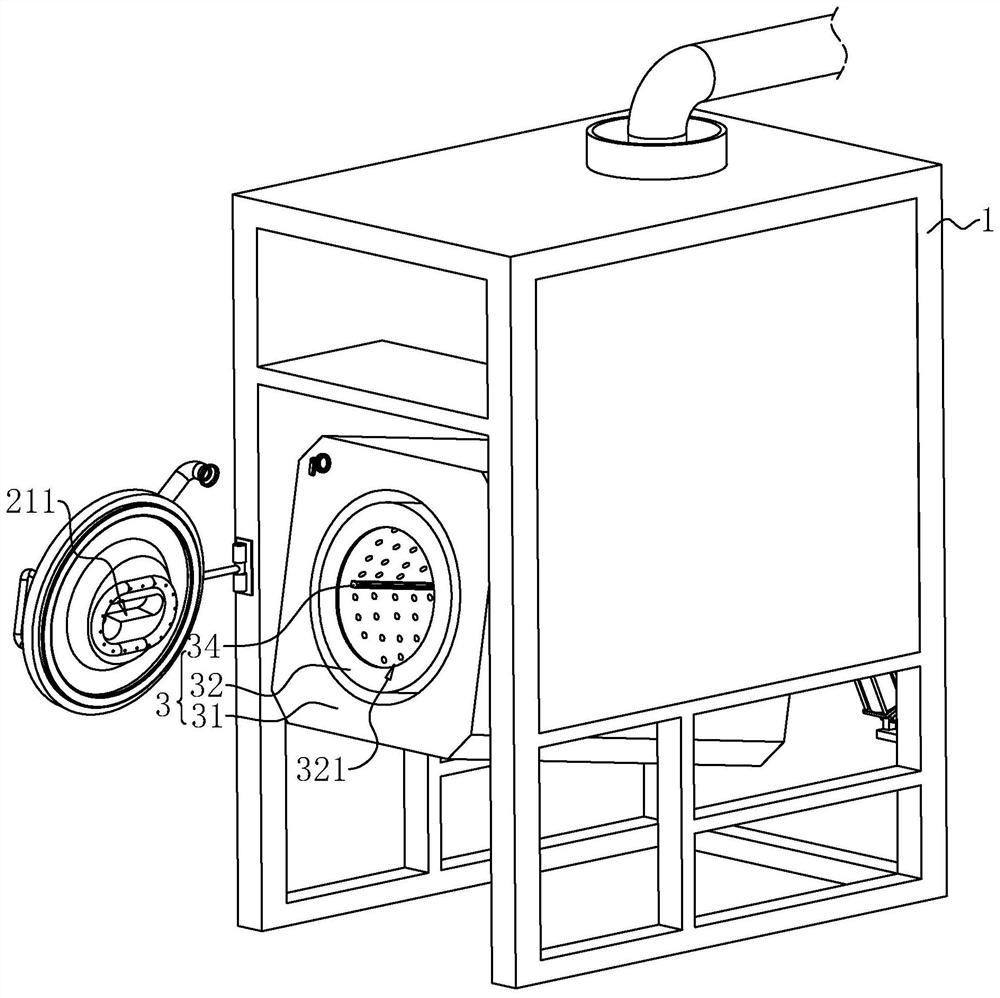

[0081] Refer Image 6 The present embodiment is different from the embodiment 1 in that Example, the temperature control module 412 further includes a three-way connector 414, wherein the first three-way connector interface header 414 and the first end 411 away from the blower duct 42 of the duct connector, a second interface connected to a second air supply pipe 415, the third interface 4126 is connected to the takeover, output takeover of the communication pipe 4126 tee connector 414 away from one end of the fan 4123, temperature transducer 4121 is attached to the fan housing 4123 the pipe section of the outlet tube.

[0082] The second air supply pipe 415 includes a plurality of nozzle extension tube 4151 and 4152, an end of the extension pipe 4151 communicating with the three-way connector 414, while another end is in communication with a plurality of nozzles 4152; 4152 a plurality of nozzles 32 in the cylinder bottom radians edges equally spaced; a plurality of blowing directi...

Embodiment 3

[0085] Refer Figure 7 The present embodiment is different from Embodiment 2 in that the inner wall 31 is fixedly connected to the bottom end of the outer cylinder 4153 with positioning seats, positioning base 4153 through 4152 defines a plurality of heads for mounting the through groove 4154, the groove 4154 extends through edges extending in the direction of curvature of the bottom roller 32 was provided in the same direction; wherein a plurality of head 4152 away from the end of the extension tube 4151 through 4154 were not extended to the outer slots.

[0086] The principles of embodiments of Example 3: the same time as a plurality of nozzles 4152 are installed inside the through slot 4154, so as to facilitate accumulation of hot air blowing nozzle 4152 in a direction 32 toward the bottom of the drum, while avoiding a leakage hole 322 by the dropwise dropping a small amount of paint directly onto the nozzle 4152, thereby increasing the use time of head 4152.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com