Source-load hybrid low-voltage large-current direct-current constant-current source system

A DC constant current and high current technology, applied in the control/regulation system, adjusting electrical variables, instruments, etc., can solve the problems of unable to meet the high-speed response of current, complex design process, high cost, etc., to reduce project cost and maintenance cost, The effect of reducing skin inductance and reducing the requirements of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

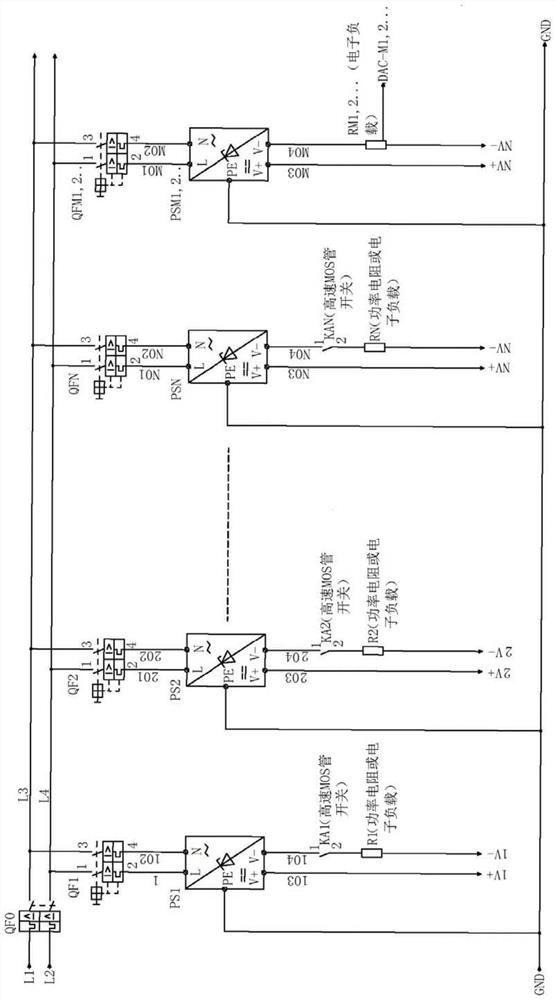

Embodiment 1

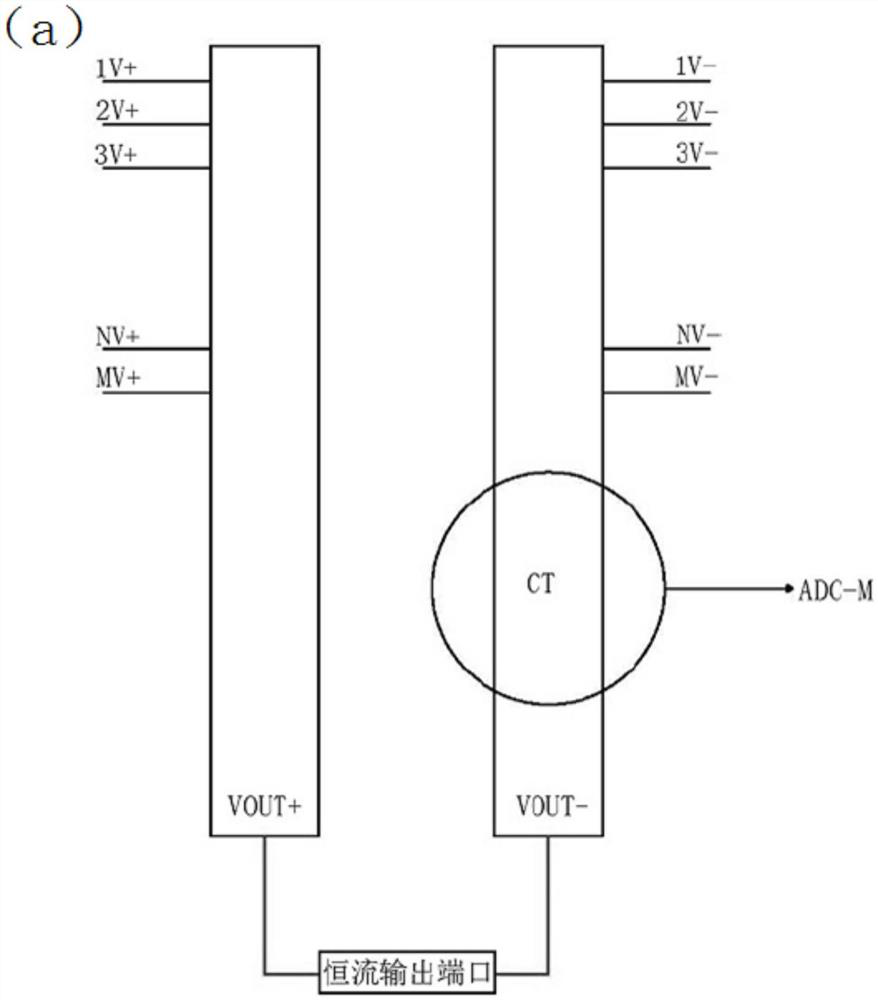

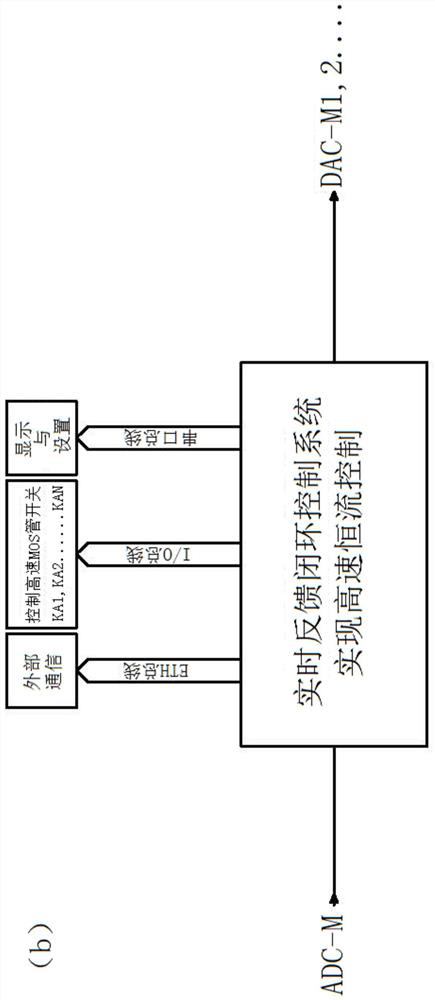

[0043] See Figure 1-2 (A), this embodiment, the ADC front end of the buffer circuit and the constant current source is connected to a large current embodiment 2 (b), according to the present invention, the large constant current source comprises a constant current power source PS small plurality of parallel disposed, each low power PS constant current source connected in series with a power corresponding to the resistance R, and each having a low-power high-speed constant current source MOS switch, switch control corresponding to the high-speed MOS-off line; exemplified: when the need to design a 5V / 10000A DC constant current source, we can split into 5V / 100A DC power supply current limiting controllable electronic 0.05 ohm load composed of a constant current source 100A is not higher than, 100 parallel, whereby a constant current is not higher than 10000A source; PSM DC power supply system further includes a plurality of low-power and the constant current source PS in paralle...

Embodiment 2

[0047] On the basis of Example 1 above, the real-time closed-loop feedback control system through the serial bus connected to the display module is provided, for setting specific parameters of the controller and a display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com