Road surface finishing machine

A finishing machine and hydraulic component technology, applied in the field of road finishing machines, can solve problems such as uneven road surface, rubber wheel wear, steering wheel slipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

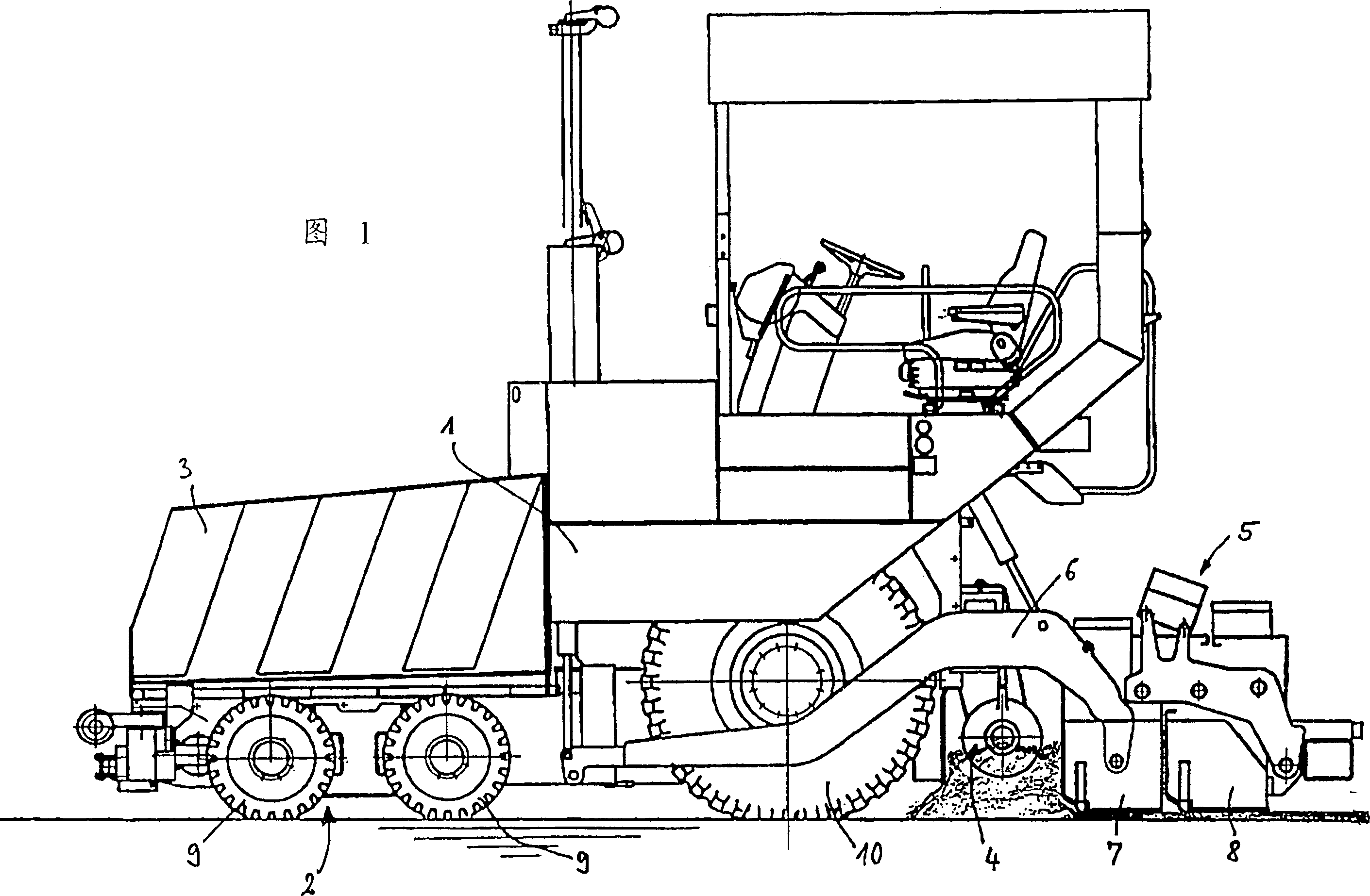

[0012] The illustrated road finishing machine comprises a chassis 1 with a wheel-driven traveling device 2, a hopper 3 at the front of the chassis 1, and a screw paver 4 at the rear, between the hopper 3 and the screw paver. A conveyor belt (not visible in the figure) is arranged between the paver 4 for conveying the mixed material to be laid from the hopper 3 via a delivery shaft to the area of the paver screw 4 . The superstructure of the road finishing machine is located above the haul shaft.

[0013] A laying plate 5 for floating laying of the mixed material to be laid is hinged on the chassis 1 via tie rods 6 . The laying board 5 is located behind the spiral paver 4 along the laying direction, and includes a base plate 7 and a stretching board 8 . These stretch plates 8 can be stretched laterally relative to the base plate and independently of each other. The base plate 7 is usually split in the middle, and the two halves of the base plate can be inclined relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com