Automatic charging and replacing system for AGV battery

An automatic, battery technology, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of no battery locking mechanism, low positioning accuracy, lack of effective monitoring, etc., to reduce the parking accuracy requirements and ensure safety. The effect of reducing the number of charging times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

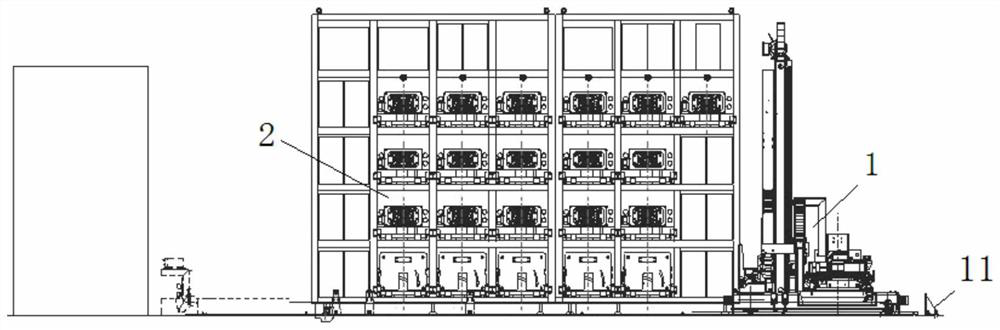

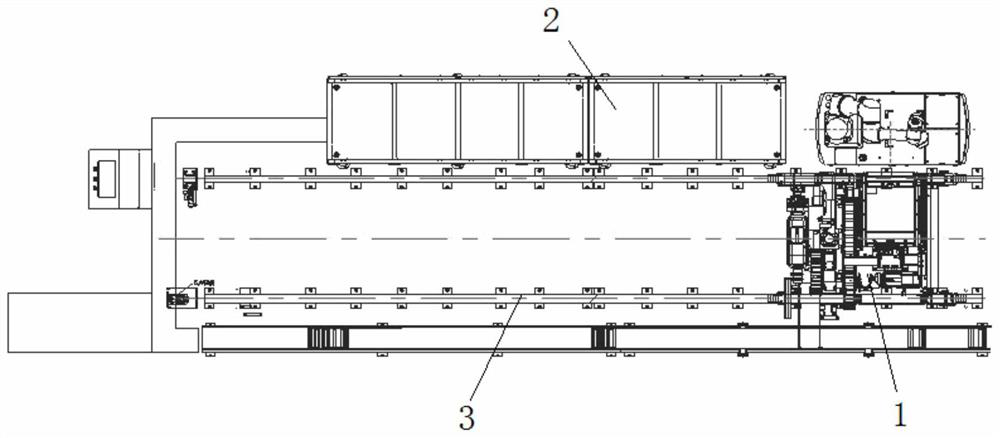

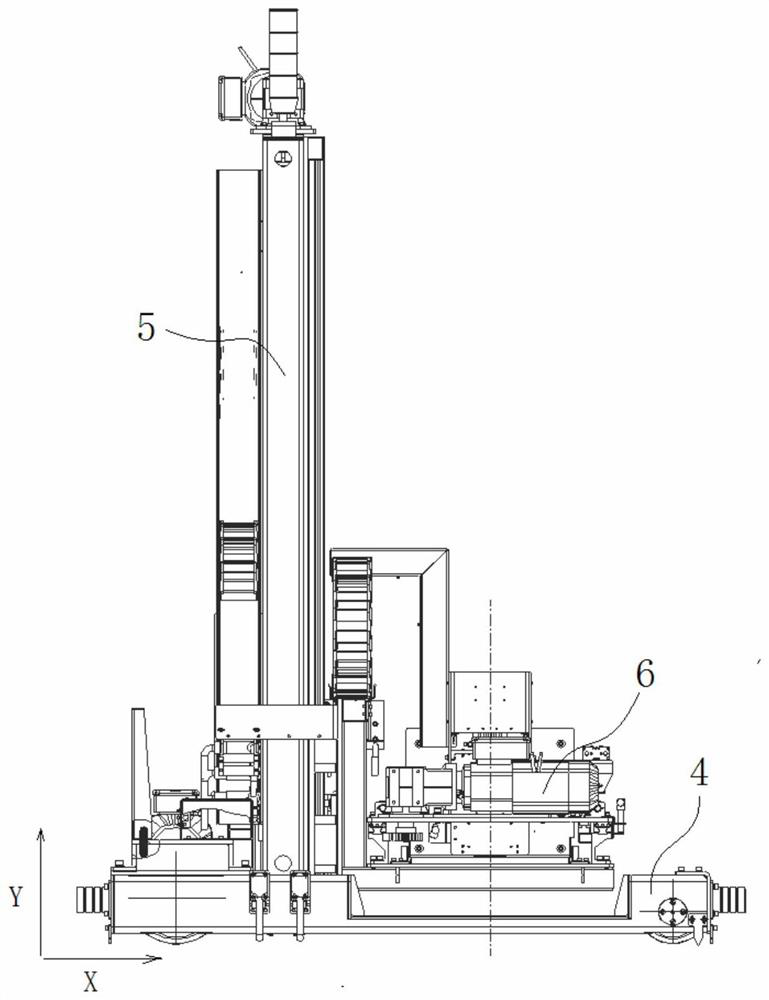

[0034] Such as Figure 1-12 As shown, the present invention includes a battery exchange car 1 and a charging cabinet 2. The battery exchange car 1 is arranged on one side of the charging cabinet 2 and walks along the X direction. The charging cabinet 2 is provided with a plurality of charging stations. The electric car 1 is provided with a Y-direction lifting mechanism 5, a Z-direction moving mechanism 6 and a pick-and-place mechanism 7, wherein the Z-direction moving mechanism 6 is driven up and down by the Y-direction lifting mechanism 5, and the Z-direction moving mechanism 6 is provided with The Z-direction mobile seat 604, and the pick-and-place mechanism 7 is arranged on the Z-direction mobile seat 604, and the pick-and-place mechanism 7 includes a hook drive device 701, a hook 705, an electric drive device 702 and an electric press contact The head 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com