Circuit board cleaning equipment and cleaning method

A technology for cleaning equipment and circuit boards, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of secondary damage to the protective layer of circuit boards, failure to react with cleaning solutions, etc., and achieve The effect of improving the quality of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

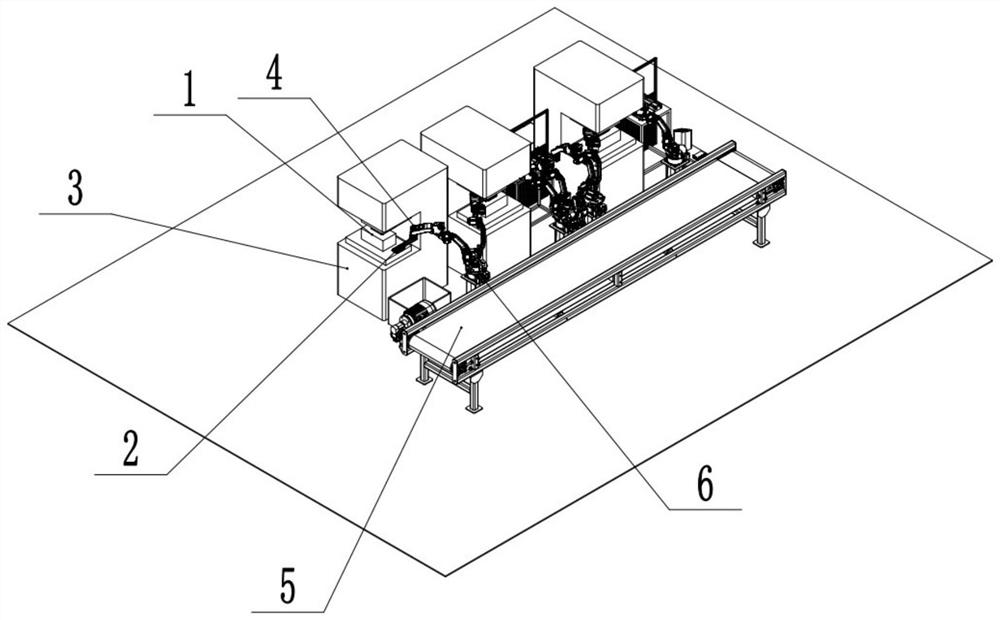

Image

Examples

Embodiment Construction

[0030] In the following description, a large amount of specific details are given to provide a more thorough understanding of the present invention. However, it will be apparent to those skilled in the art that the present invention can be implemented without one or more of these details. In other examples, in order to avoid confusion with the present invention, there is no description thereof in the art.

[0031] The present application discloses both to improve the quality of rust clearance, but also can reduce board soak time and thus avoid the secondary damage caused by the protective layer of the circuit board circuit board cleaning equipment.

[0032] The circuit board cleaning apparatus comprising: a cleaning vessel 1, the clamp assembly and a hydrodynamic component 2 3.

[0033] Cleaning vessel 1 is fixed on a table, and the cleaning vessel 1 is accommodated within a predetermined amount of the washing solution.

[0034] The clamp assembly 21 is connected to the cleaning v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com