Organic rice processing technology

A processing technology, organic rice technology, applied in application, grain processing, grain milling, etc., can solve the problems of unable to maintain rice, ventilation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A kind of organic rice processing technology, comprises the following steps:

[0034] S1: put the rice into the rice processing device;

[0035] S2: Introducing air into the rice to keep the rice in a ventilated state;

[0036] S3: Stir the rice in the rice processing device to further maintain the ventilation of the rice;

[0037] S4: The rice is divided into multiple layers for storage.

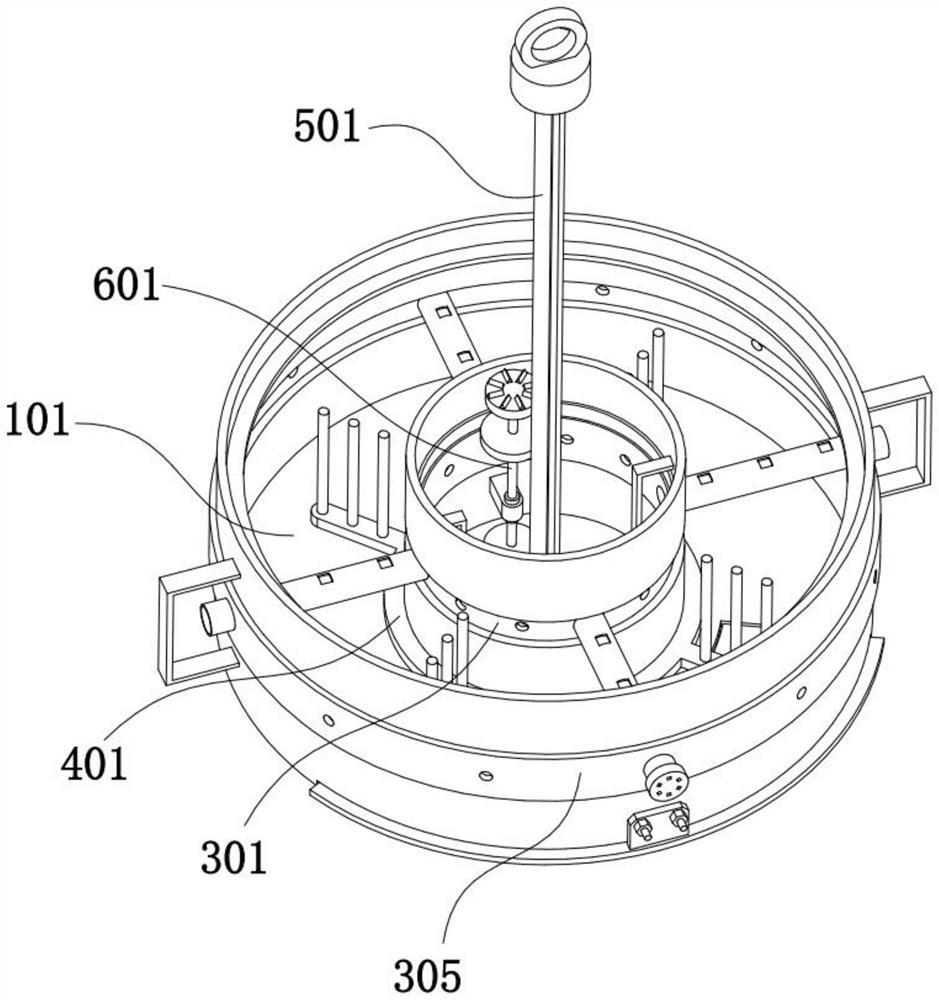

[0038] see Figure 2-5 As shown, shown in the figure is an embodiment of storing rice through a ring-shaped area, wherein,

[0039] Since the rice processing device comprises a ring plate 101, an outer cylinder 104 and an inner cylinder 108, the outer cylinder 104 and the inner cylinder 108 are arranged on the upper side of the ring plate 101, and the ring plate 101, the outer cylinder 104, and the inner cylinder 108 are coaxially arranged, The ring plate 101, the outer cylinder 104 and the inner cylinder 108 form an annular rice storage area, and then rice can be stored through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com