Lidless bga socket apparatus for testing semiconductor device

A semiconductor, capless technology, used in measurement devices, measurement device housings, coupling devices, etc., can solve the problems of IC test reliability reduction, durability decline, a large number of components, etc., to improve contact deterioration and temperature maintenance. The effect of uniform and reduced test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

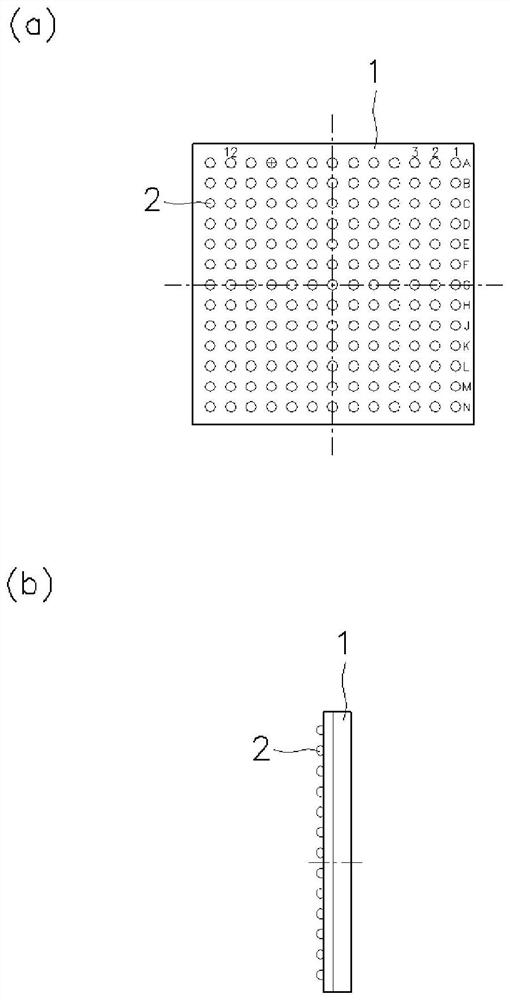

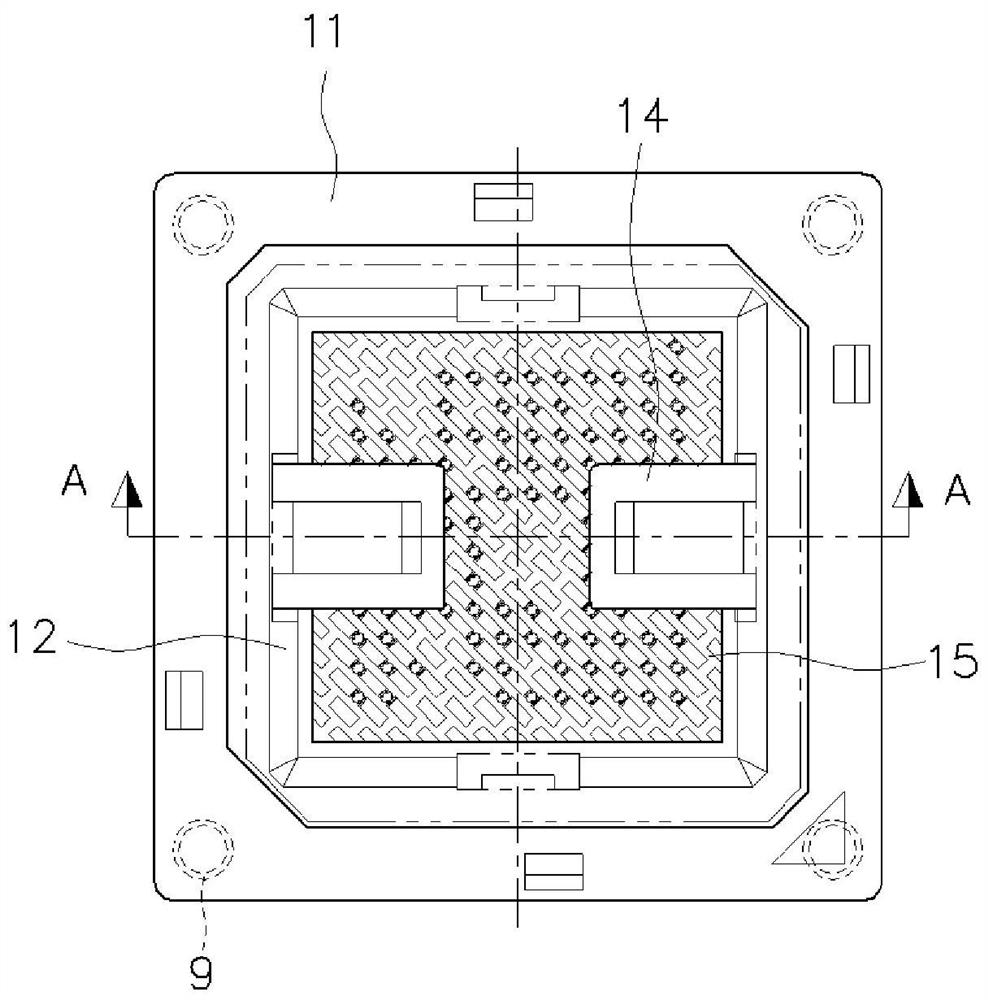

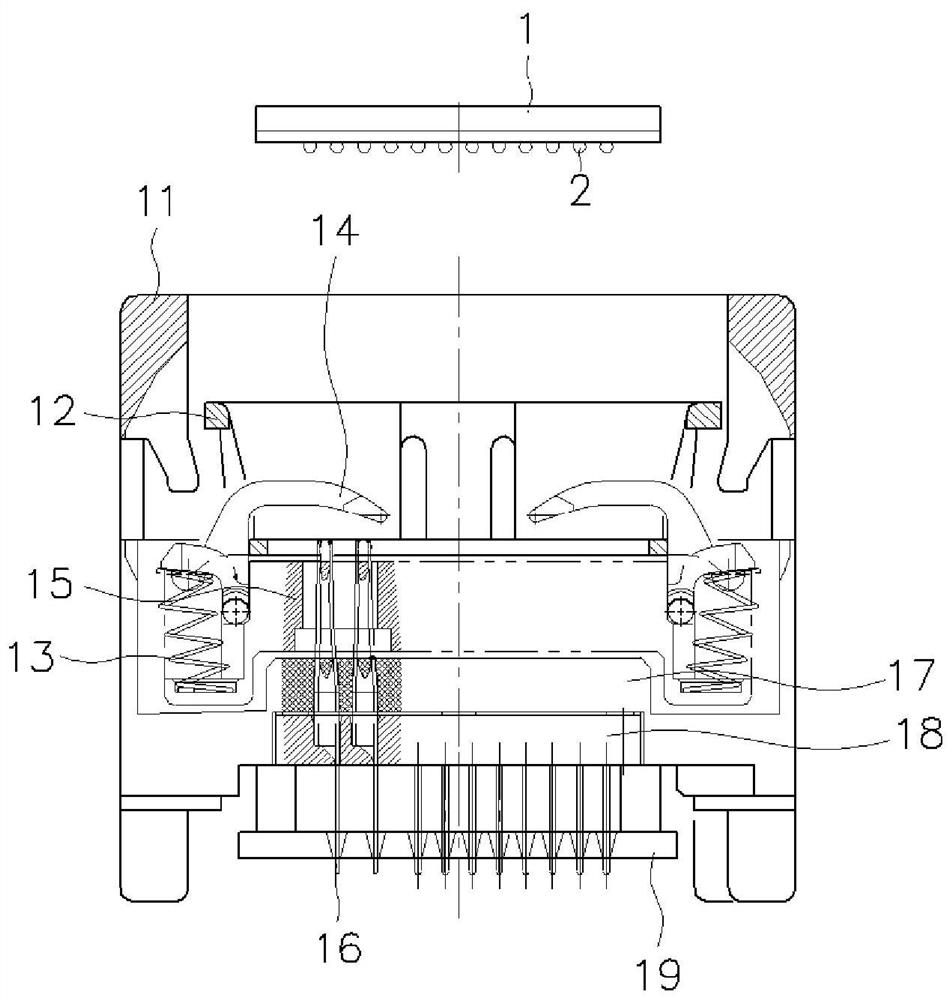

[0084] Image 6 It is a plan configuration diagram of a coverless BGA socket device (hereinafter referred to as "socket device") according to the first embodiment of the present invention, Figure 7 for along Image 6 The cross-sectional composition diagram of the B-B line, Figure 8 for along Image 6 The cross-sectional composition diagram of the C-C line.

[0085] refer to Figure 6 to Figure 8, the socket device 200 of the present embodiment includes: a contact 100 having an upper tip portion, having elasticity in the lateral direction and electrically contacting a terminal of IC1; The slider receiving part 210b formed by 210a is recessed, and the cam support part 212a is formed by recessing from the upper surface 210a around the slider receiving part 210b and constitutes one end sidewall, and the contact 100 is fixed on the lower surface of the slider receiving part 210b; The slider 230 is provided so as to be able to slide back and forth in the horizontal direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com