Road engineering pavement quality detection device

A detection device and engineering technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of single situation and difficulty in directly and accurately measuring the roughness of the road surface, so as to achieve the effect of accurate detection results and guaranteed integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

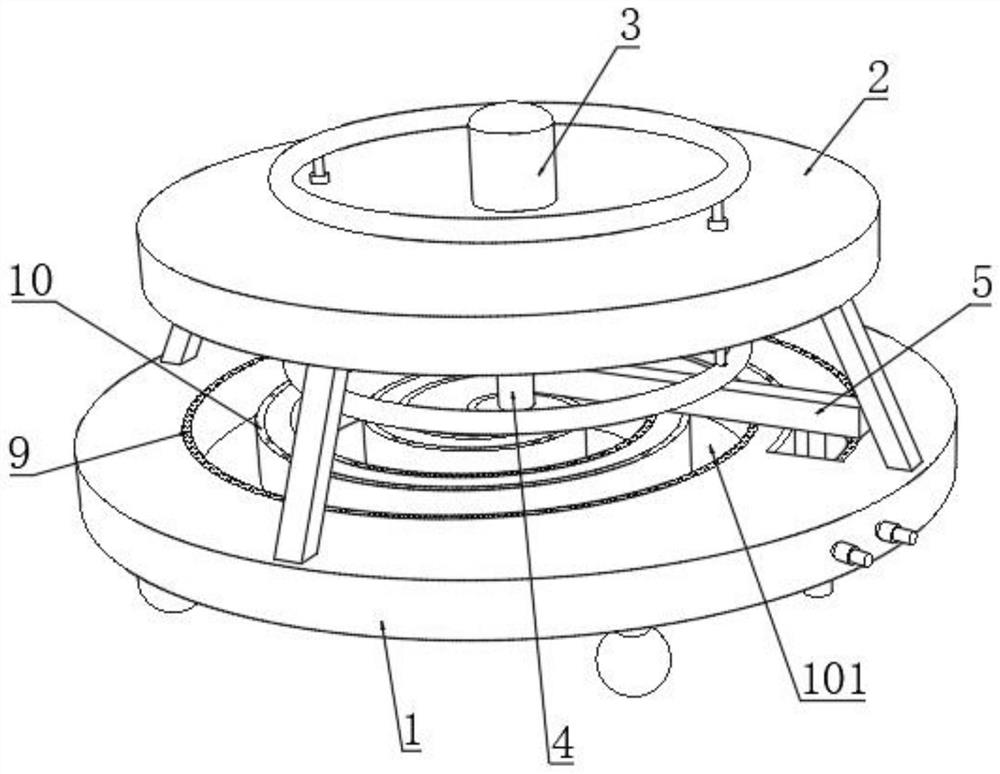

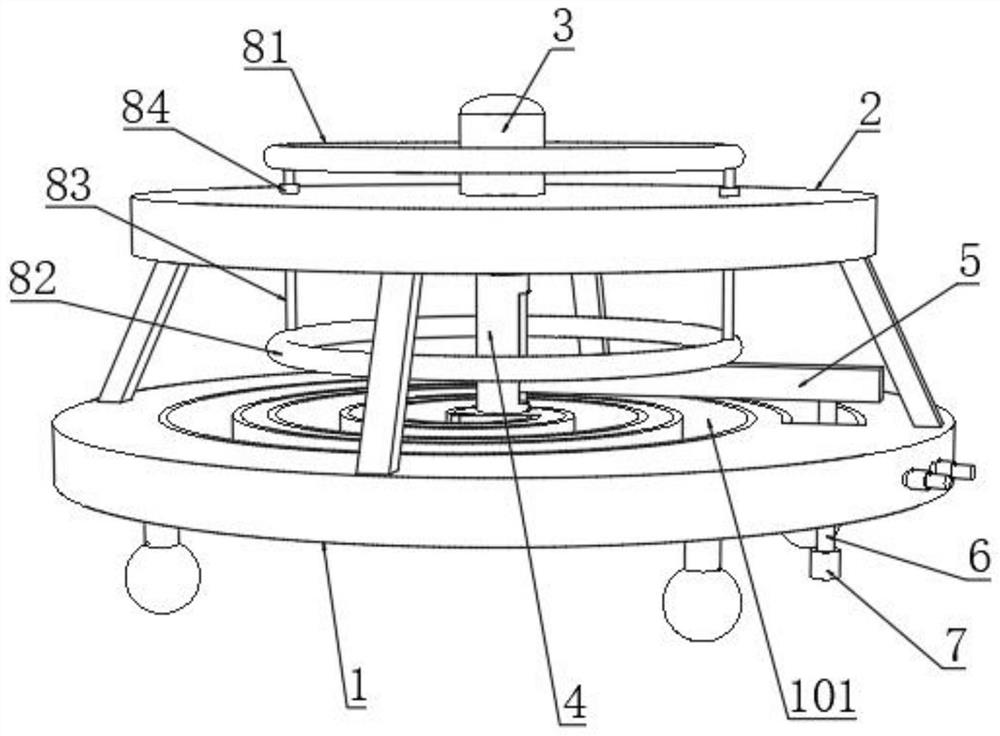

[0045] see figure 1 and figure 2 , a road surface quality detection device for highway engineering, comprising a chassis 1 with rollers at the bottom, the rollers are equipped with a self-locking mechanism for easy fixing, the upper side of the chassis 1 is provided with a top plate 2, and the chassis 1 and the top plate 2 are fixedly connected There are a plurality of evenly distributed diagonal struts, the upper end of the top plate 2 is fixedly connected to the motor 3, the output end of the motor 3 penetrates the top plate 2 downwards and is fixedly connected to the vertical shaft 4, the lower end of the vertical shaft 4 is connected to the upper end of the chassis 1 touch.

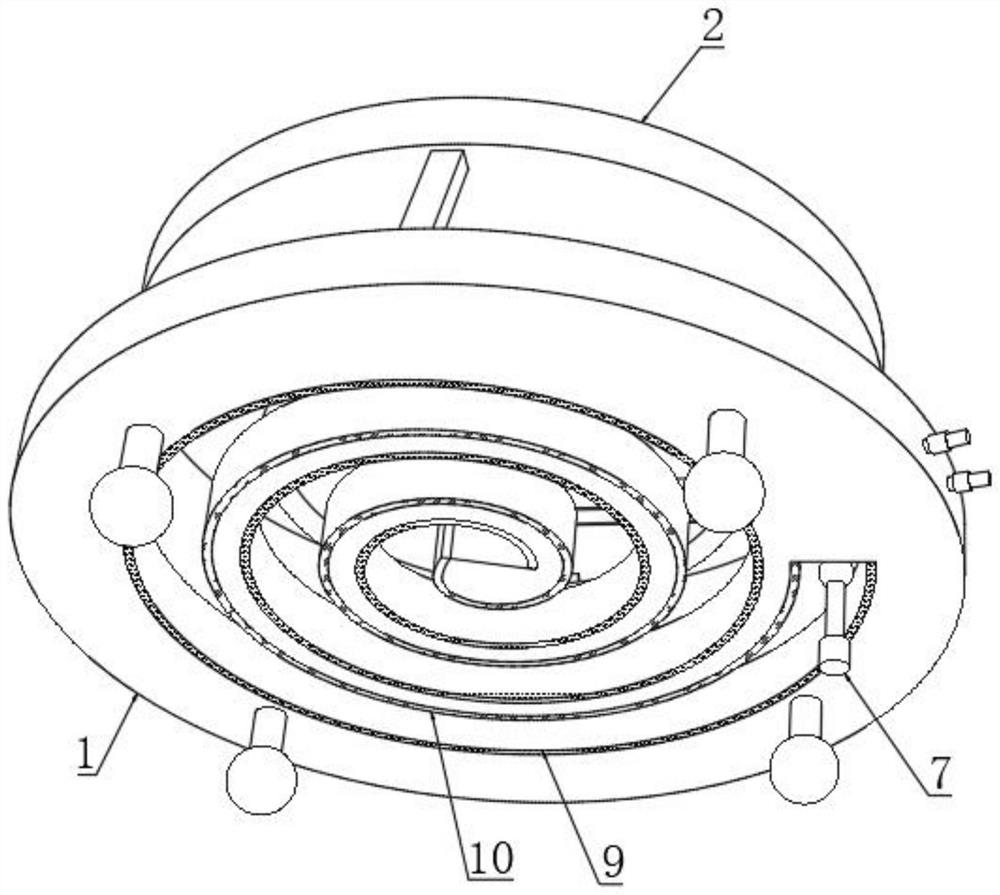

[0046] see figure 2 and image 3 The side end of the vertical shaft 4 is slidably connected to a horizontal plate 5, the lower end of the horizontal plate 5 is slidably connected to a rotating rod 6, and the lower end of the rotating rod 6 is fixedly connected to a detection contact 7, and a spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com