Gravel particle surface edge angle measurement method based on three-dimensional laser scanning

A particle surface and angle measurement technology, which is applied in the field of geotechnical engineering, can solve the problems of insufficient angle measurement of crushed stones, and achieve clear geometric and physical meanings, accurate measurement results, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

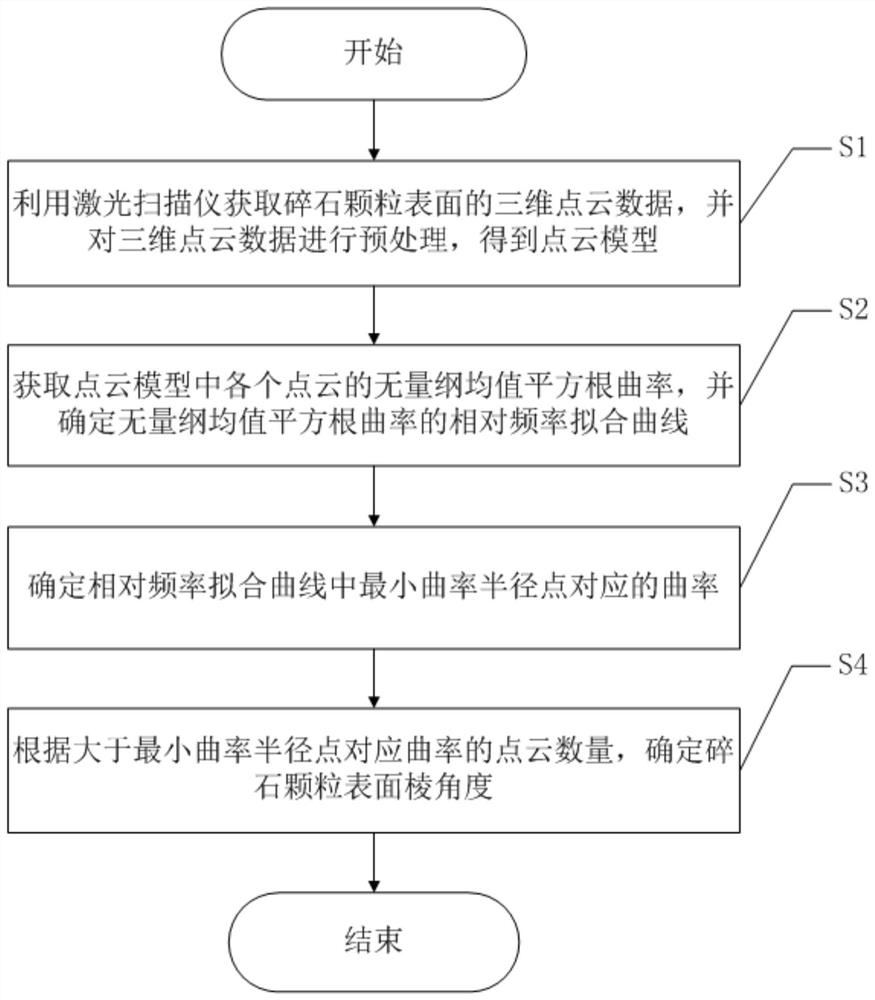

[0038] Such as figure 1 As shown, the present invention provides a method for measuring the surface angularity of crushed stone particles based on three-dimensional laser scanning, comprising the following steps:

[0039] S1: Use a laser scanner to obtain 3D point cloud data on the surface of gravel particles, and preprocess the 3D point cloud data to obtain a point cloud model;

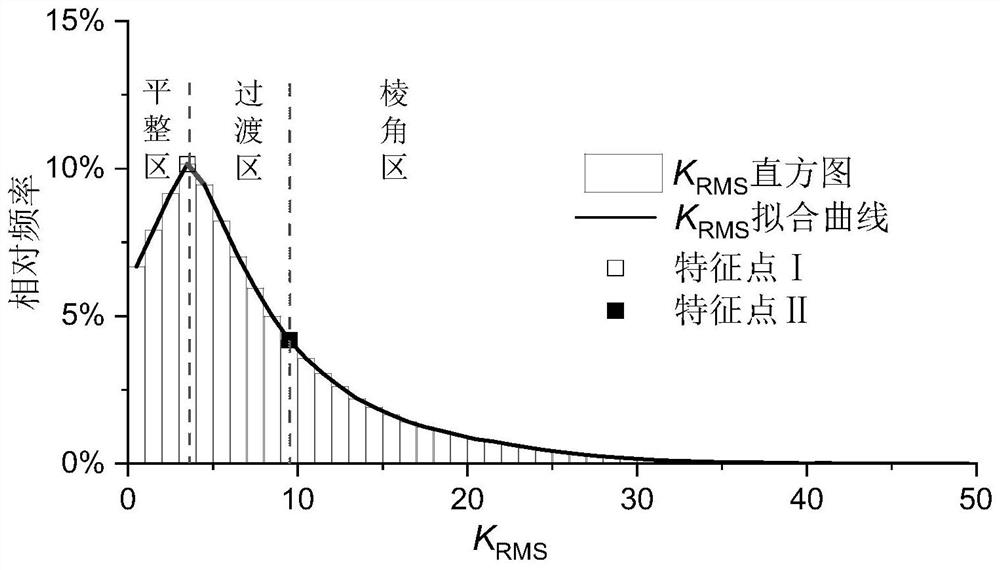

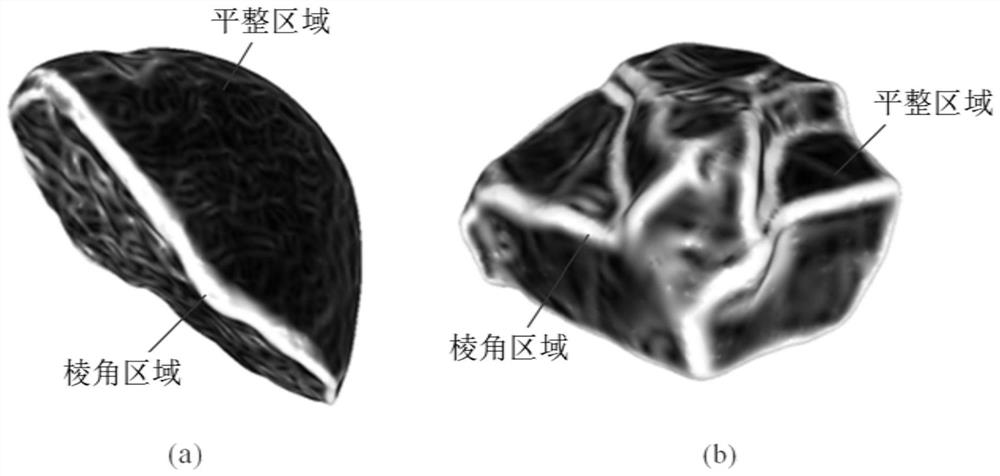

[0040] S2: Obtain the dimensionless mean square root curvature of each point cloud in the point cloud model, and determine the relative frequency fitting curve of the dimensionless mean square root curvature;

[0041] S3: Determine the curvature corresponding to the minimum curvature radius point in the relative frequency fitting curve;

[0042] S4: Determine the surface edge angle of gravel particles according to the number of point clouds whose curvature is greater than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com