Fabricated type prefabricated light concrete outer wall enclosure plate

A technology for concrete exterior walls and enclosure panels, applied to walls, building components, insulation, etc., can solve problems such as complex construction, unsatisfactory construction, and long construction period, so as to improve connection strength and compactness, and prevent relative displacement and deformation , to meet the effect of wind pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

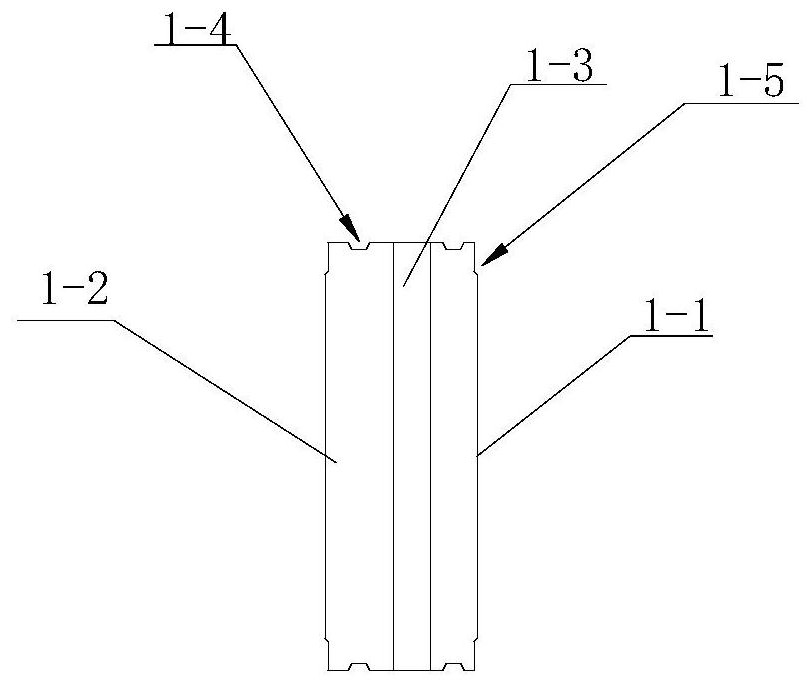

[0027] Example 1: See Figure 1 to Figure 5 , a prefabricated prefabricated light concrete outer wall enclosure, the outer wall enclosure includes an outer leaf plate 1-1 and an inner leaf plate 1- 2, and the insulation layer 1-3 bonded between the outer blade and the inner blade; the insulation layer can be made of building insulation materials in the prior art, such as polystyrene board; the thickness of the outer blade is less than or equal to The thickness of the inner blade. The specific thickness can be designed according to the actual building requirements. A vertical grouting female groove 1-4 is provided on the outer leaf plate and the inner leaf plate on the same vertical splicing surface. The present invention adopts a composite process to compound the heat preservation board and the inner and outer blades to ensure the connectivity of the heat preservation board and form an integrated heat preservation structure, which replaces the traditional external hanging he...

Embodiment 2

[0029] Example 2, see Figure 6 , steel mesh 1-6 is arranged inside the outer leaf plate and the inner leaf plate. Improve the compression and bending resistance of the board body, and improve the safety of use.

Embodiment 3

[0030] Example 3, see Figure 7 , the steel mesh in the outer leaf plate and the inner leaf plate is provided with tension bars 1-7, and the tension bars pass through the insulation layer to form a built-in steel skeleton structure. The steel skeleton formed by the above combination can also be Steel truss structure. To further improve its compressive and flexural capacity, the inner and outer blades are connected into a stressed whole through the steel skeleton, and then can bear a large wind pressure and earthquake resistance level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com