A large plate electrolytic refinement lead cathode plate copper rod receiving buffer protection device

An electrolytic refining and protection device technology, applied in the direction of electrolytic components, electrolytic process, electrodes, etc., can solve the problems of copper rod damage, production cost increase, copper rod damage, etc., and achieve the effect of reduced friction and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

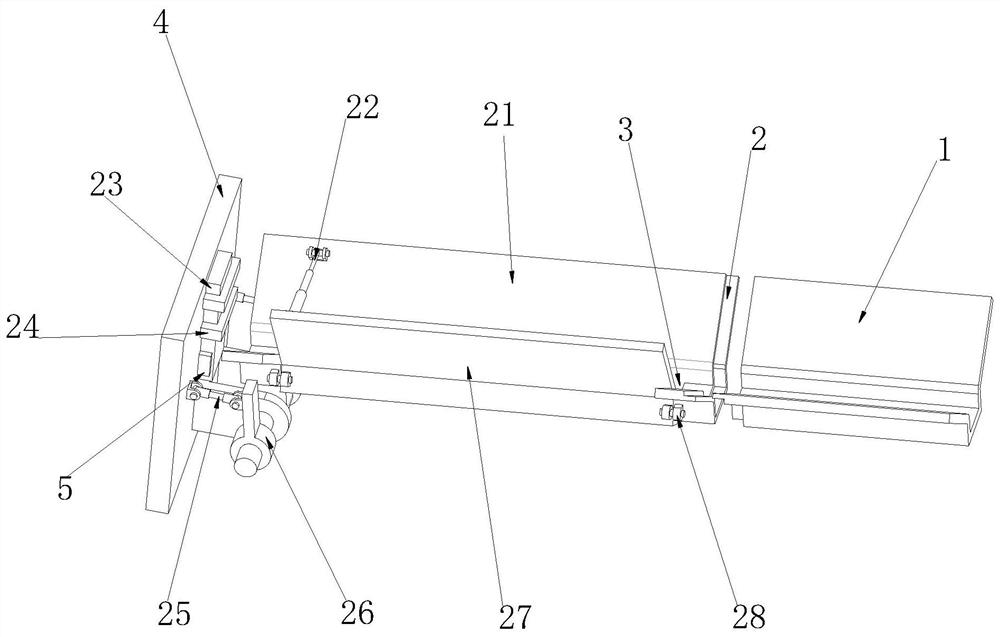

[0038] see figure 1 and Figure 7As shown, a large electrode plate electrolytic refining lead cathode plate copper rod receiving buffer protection device includes a slideway 1 and an end plate 4, one side of the outer side wall of the end plate 4 is provided with a slideway 1, and the outer side wall of the end plate 4 is close to the slideway 1. A feeding mechanism 2 is arranged at one side of the feeding mechanism. The feeding mechanism 2 includes a chute 21. The chute 21 is rotatably connected with the end plate 4 through a rotating seat 28, and a middle position on one side of the outer side wall of the chute 21 is rotatably connected through the rotating seat 28. The movable plate 27, the movable plate 27 is rotatably connected with the chute 21 through the rotating seats 28 on both sides, the inner side wall of the chute 21 corresponding to the position of the movable plate 27 is connected with the unloading telescopic rod 22 through the rotating seat 28, and through the...

Embodiment 2

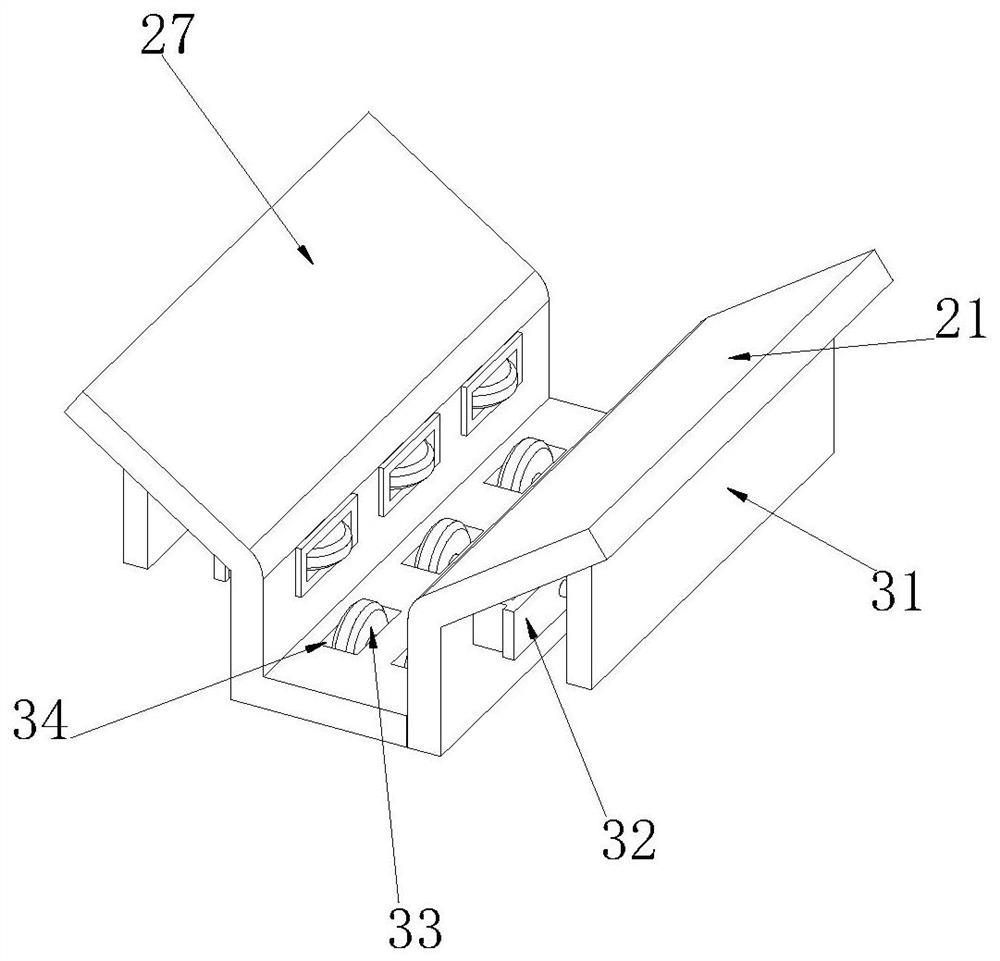

[0041] During the sliding process of the copper rod along the inclined surface inside the chute 1 and the chute 21, the friction with the inner side wall and the bottom surface of the chute 1 and the chute 21 is relatively large, so that the surface of the copper rod formed by the copper skin wrapped by the steel core is larger. The copper skin is worn, and the copper rod cannot be put into use after the copper skin is worn;

[0042] see Figure 1-2 and Figure 5-6 As shown, the inner side wall of the chute 21 is provided with a sliding material mechanism 3, and the sliding material mechanism 3 includes a roller 33. There are holes 34 on both sides of the inner side wall of the chute 21 and the position corresponding to the roller 33 on the inner lower surface. There are holes 34 on the sides, and each hole 34 is connected with a roller 33 through a rotating shaft. A movable frame 32 is slidably connected to the inner side of the hole 34 on both sides of the inner side wall o...

Embodiment 3

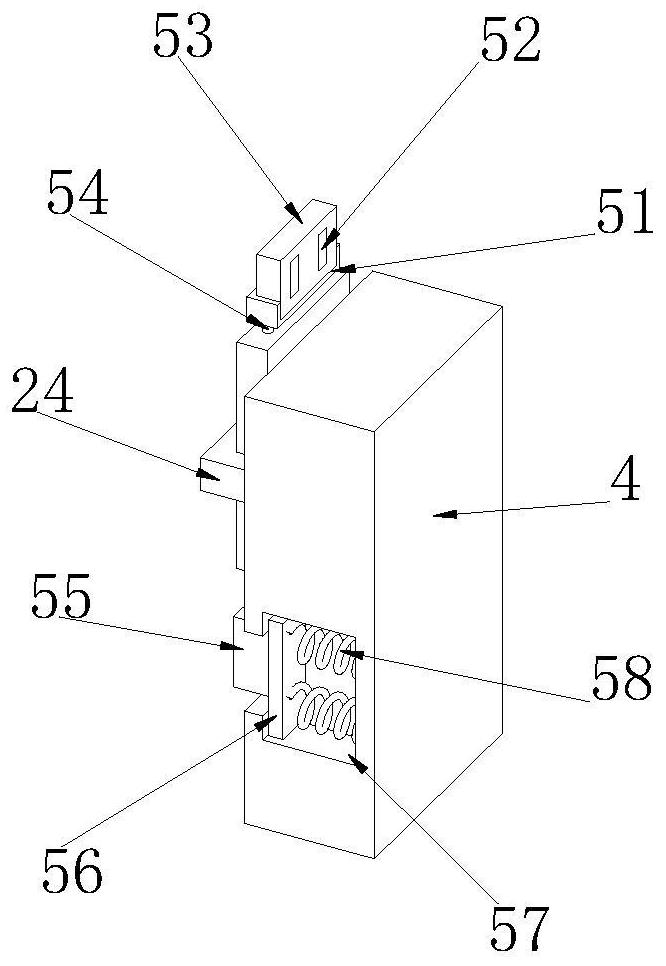

[0045] The copper rod collides with the rubber pad 23 on the end plate 4 after sliding on the inside of the chute 1 and the chute 21. The increase in the number of collisions is easy to cause damage to the rubber pad 23, and the cushioning effect of the damaged rubber pad 23 decreases, and the chute 1 The friction received after adding the roller 33 to the inner side of the chute 21 is reduced, the sliding speed is increased, the collision force with the rubber pad 23 is increased, and the damage to the rubber pad 23 is increased;

[0046] see figure 1 , Figure 3-4 and Figure 8 As shown, an auxiliary mechanism 5 is provided at the position of the outer side wall of the end plate 4 corresponding to the position of the rubber pad 23, and two sides of the outer side wall of the end plate 4 corresponding to the position of the rubber pad 23 are provided with telescopic grooves 57, and the inner side wall of the telescopic groove 57 is slidably connected to the limit plate 56. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com