Method for reducing long-distance transportation scratch of empty metal spray can

A technology for long-distance transportation and spray cans, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of abrasion, poor quality of long-distance freight trucks, complex road conditions, etc., to reduce the probability of collision scratches, meet the Long-distance transportation needs, the effect of improving scratch resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

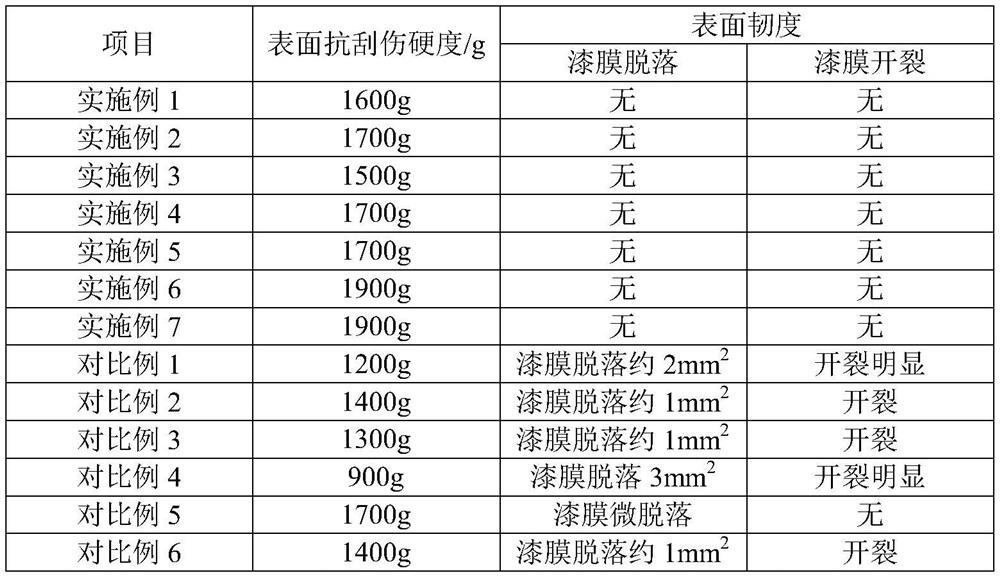

Examples

Embodiment 1

[0026] A method for reducing scratches during long-distance transportation of empty metal spray cans, comprising coating the surface of the tinplate sheet used in the preparation of metal spray cans, and after printing graphics, coating a protective varnish layer, specifically as follows:

[0027] (1) External coating of tinplate sheet: It is a conventional roller coating process for metal flat plates. The model produced by Foshan Rulin Chemical Co., Ltd. is MC-UV-C504 product, which is traditionally heat-cured at 170°C and the coating film thickness is 13g / m 2 ;

[0028] (2) Graphic printing: It is a conventional process for metal packaging, specifically forming a printing ink layer through two printings:

[0029] 1P: ULED-H1408 high temperature yellow (SCP ULED series ink produced by Shanghai Chaocai Ink Co., Ltd.);

[0030] ULED-Z3401 four-color blue (SCP ULED series ink produced by Shanghai Chaocai Ink Co., Ltd.);

[0031] ULED-H5001 four-color black (SCP ULED series ink...

Embodiment 2

[0038] A method for reducing scratches during long-distance transportation of empty metal spray cans, comprising coating the surface of the tinplate sheet used in the preparation of metal spray cans, and after printing graphics, coating a protective varnish layer, specifically as follows:

[0039] (1) External coating of tinplate sheet coating: metal plate conventional rubber roller roll coating process, the model produced by Foshan Rulin Chemical Co., Ltd. is MC-UV-C504 product, 170 ℃ traditional thermosetting, coating thickness 15g / m 2 ;

[0040] (2) Graphic printing: It is a conventional process for metal packaging, specifically forming a printing ink layer through two printings:

[0041]1P: ULED-H1408 high temperature yellow (SCP ULED series ink produced by Shanghai Chaocai Ink Co., Ltd.);

[0042] ULED-Z3401 four-color blue (SCP ULED series ink produced by Shanghai Chaocai Ink Co., Ltd.);

[0043] ULED-H5001 four-color black (SCP ULED series ink produced by Shanghai Cha...

Embodiment 3

[0050] A method for reducing scratches during long-distance transportation of empty metal spray cans, comprising coating the surface of the tinplate sheet used in the preparation of metal spray cans, and after printing graphics, coating a protective varnish layer, specifically as follows:

[0051] (1) External coating of tinplate sheet coating: metal plate conventional rubber roller roll coating process, the model produced by Foshan Rulin Chemical Co., Ltd. is MC-UV-C504 product, 172 ℃ traditional thermosetting, coating thickness 15g / m 2 ;

[0052] (2) Graphic printing: It is a conventional process for metal packaging, specifically forming a printing ink layer through two printings:

[0053] 1P: ULED-H1408 high temperature yellow (SCP ULED series ink produced by Shanghai Chaocai Ink Co., Ltd.);

[0054] ULED-Z3401 four-color blue (SCP ULED series ink produced by Shanghai Chaocai Ink Co., Ltd.);

[0055] ULED-H5001 four-color black (SCP ULED series ink produced by Shanghai Ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com