Hydraulic valve block quality detection device and detection method

A technology of detection device and hydraulic valve, which is applied in the direction of measurement device, fluid pressure actuation device, fluid pressure actuation system testing, etc., can solve problems such as imperfect device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

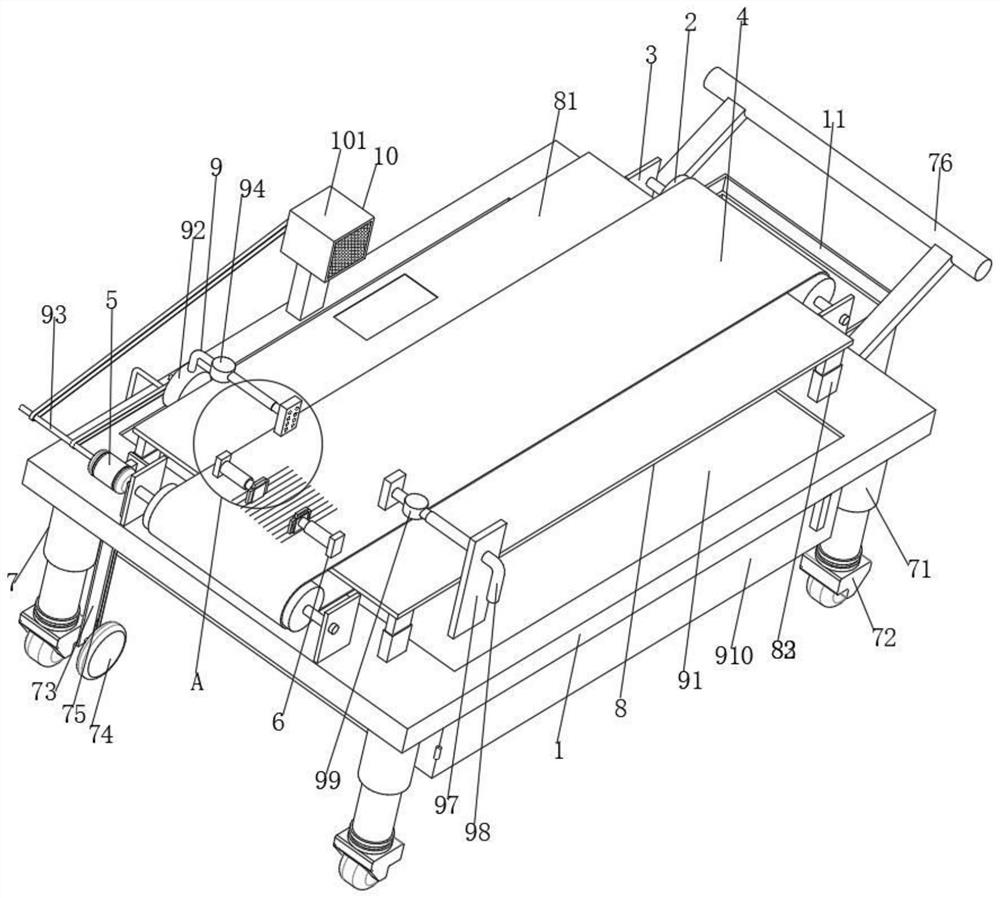

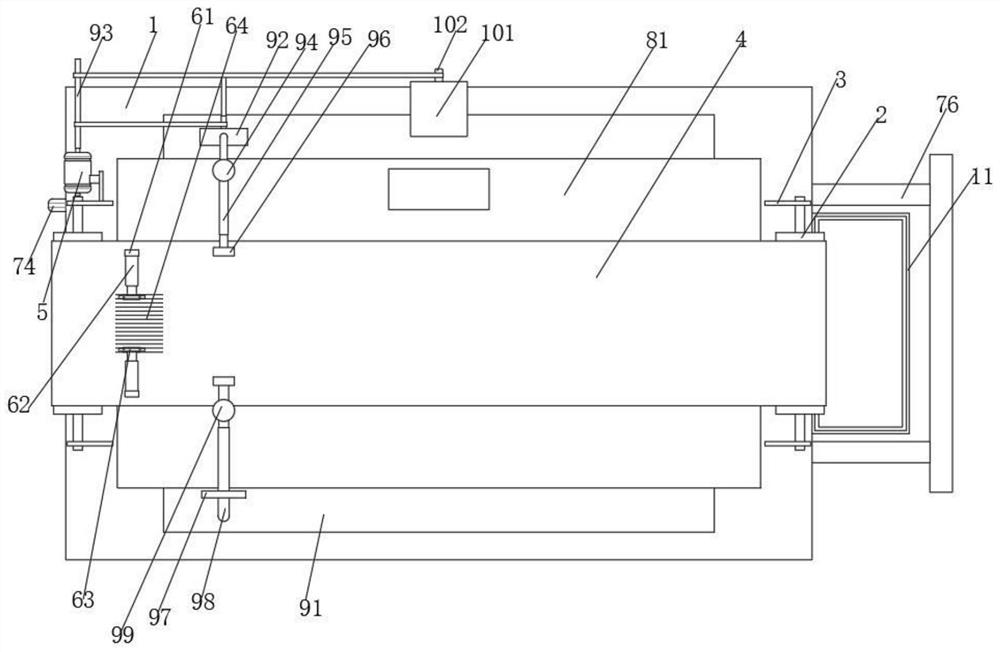

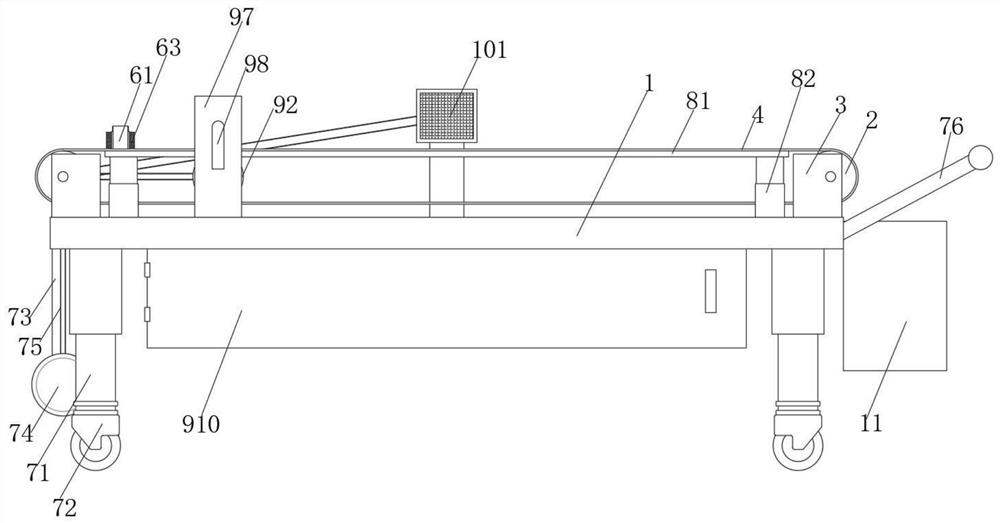

[0025] The present invention provides such Figure 1-5 The shown hydraulic valve block quality detection device and detection method include a return-shaped plate 1, and both sides of the top of the return-shaped plate 1 are provided with transmission shaft cylinders 2, and the front and back sides of the outer sides of the two transmission shaft cylinders 2 are rotated. Connected with a brace 3, the bottom of the brace 3 is respectively fixedly connected to the four corners of the top of the back-shaped plate 1, and the middle part of the outer side of the two transmission shaft tubes 2 is connected by a transmission belt 4, and the transmission shaft tube 2, the brace 3 and the transmission The use of the material belt 4 facilitates the transmission of the hydraulic valve block. The back of the left transmission shaft cylinder 2 is fixedly connected to the double-axis motor 5, and the right side of the double-axis motor 5 is fixedly connected to the back of the support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com