Multi-mode force control lossless grabbing device for intelligent production line

A grasping device and multi-modal technology, applied in the direction of program-controlled manipulators, manipulators, chucks, etc., can solve the problem of being unable to adapt to grasping of various objects and easily deformable objects, unable to directly judge whether the grasping action is successful, and unable to know Object information and other issues, to achieve the effect of simple structure, low cost, and avoid damage to objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be noted that the following examples are intended to facilitate the understanding of the present invention, but not to limit it in any way.

[0063] A kind of preferred embodiment of the present invention is:

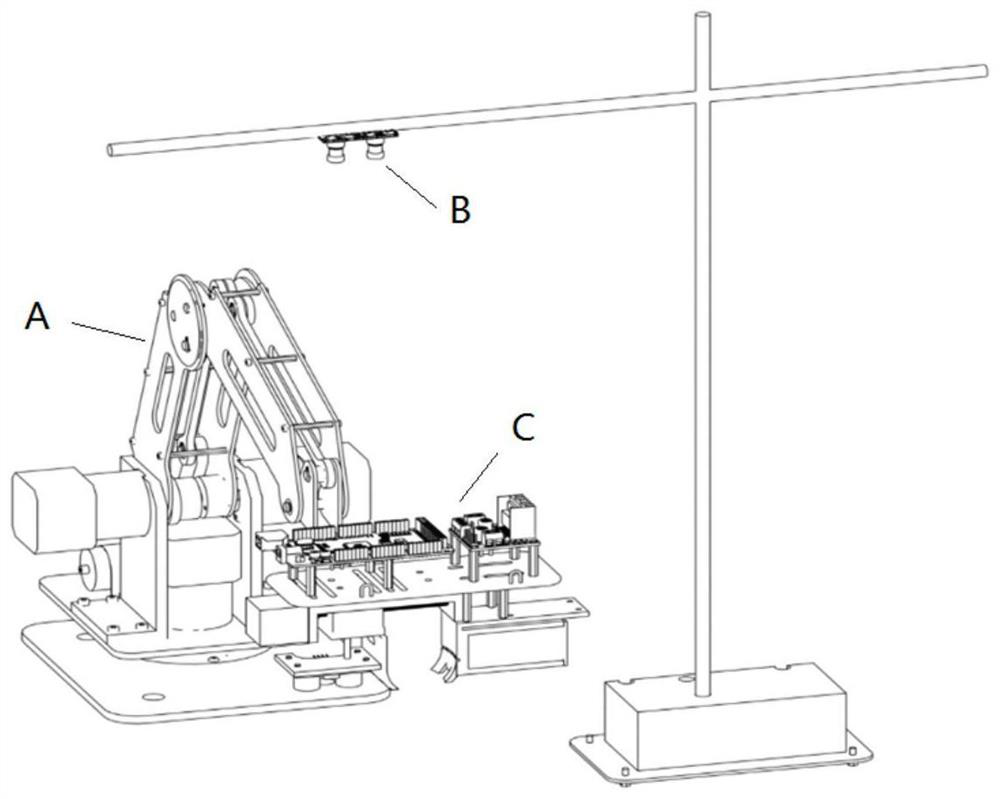

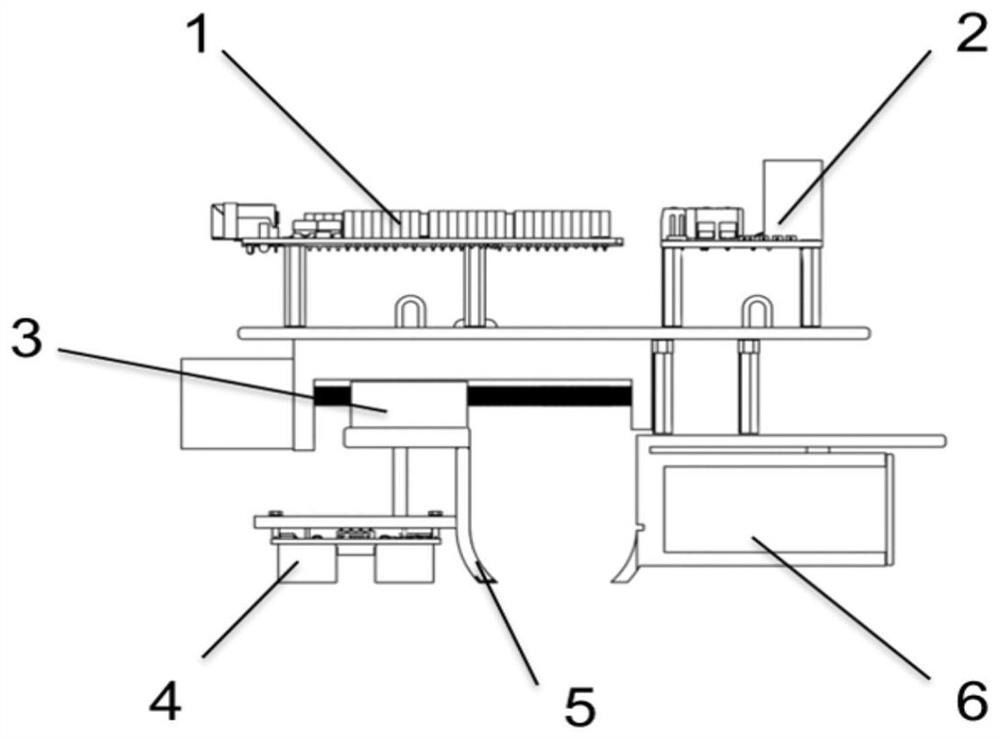

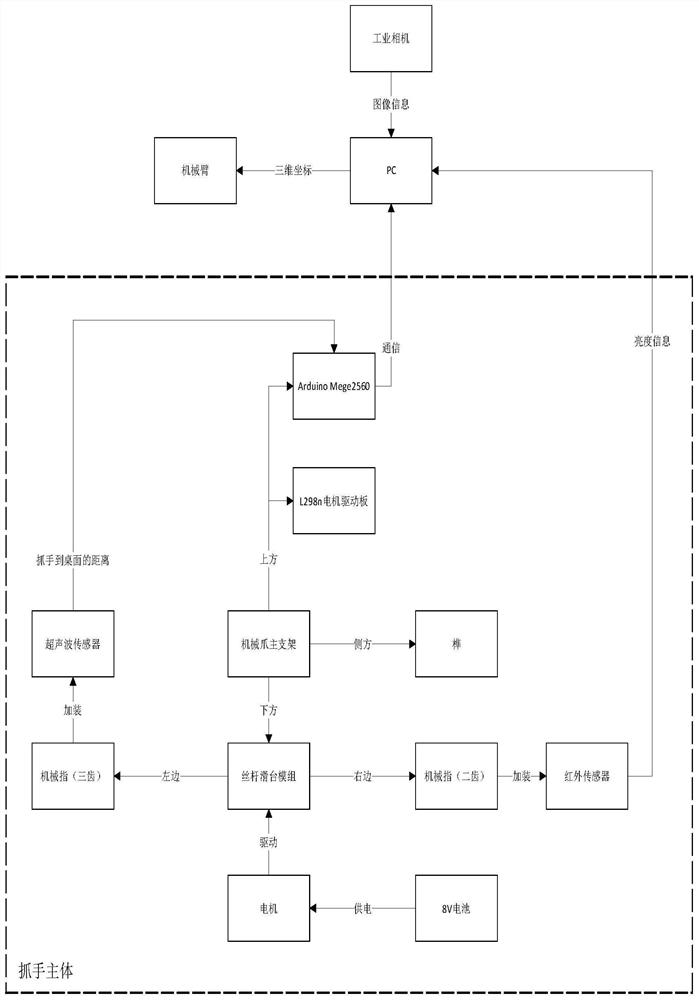

[0064] The multi-modal non-destructive force control grasping device includes an initial setting force detection subsystem, an output force control subsystem, and a force control gripper mechanical component. The modal information sources of the initial setting force detection subsystem include cameras and film pressure sensors. The modal information sources of the output force control subsystem include thin-film pressure sensors and infrared detection modules;

[0065] The force control gripper is a two-finger mechanical claw, and the mechanical components of the gripper include a main bracket, a screw slide, toothed fingers and ten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com