Rotary granulation preparation method

A technology of rotary granulation and main body, applied in the field of rotary granulation preparation, can solve the problems of the difficulty of cleaning the easily adhering raw materials, reduce the granulation quality of the device, and the inconsistency of particle size, etc., so as to avoid shaking, reduce the difficulty and increase the output uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

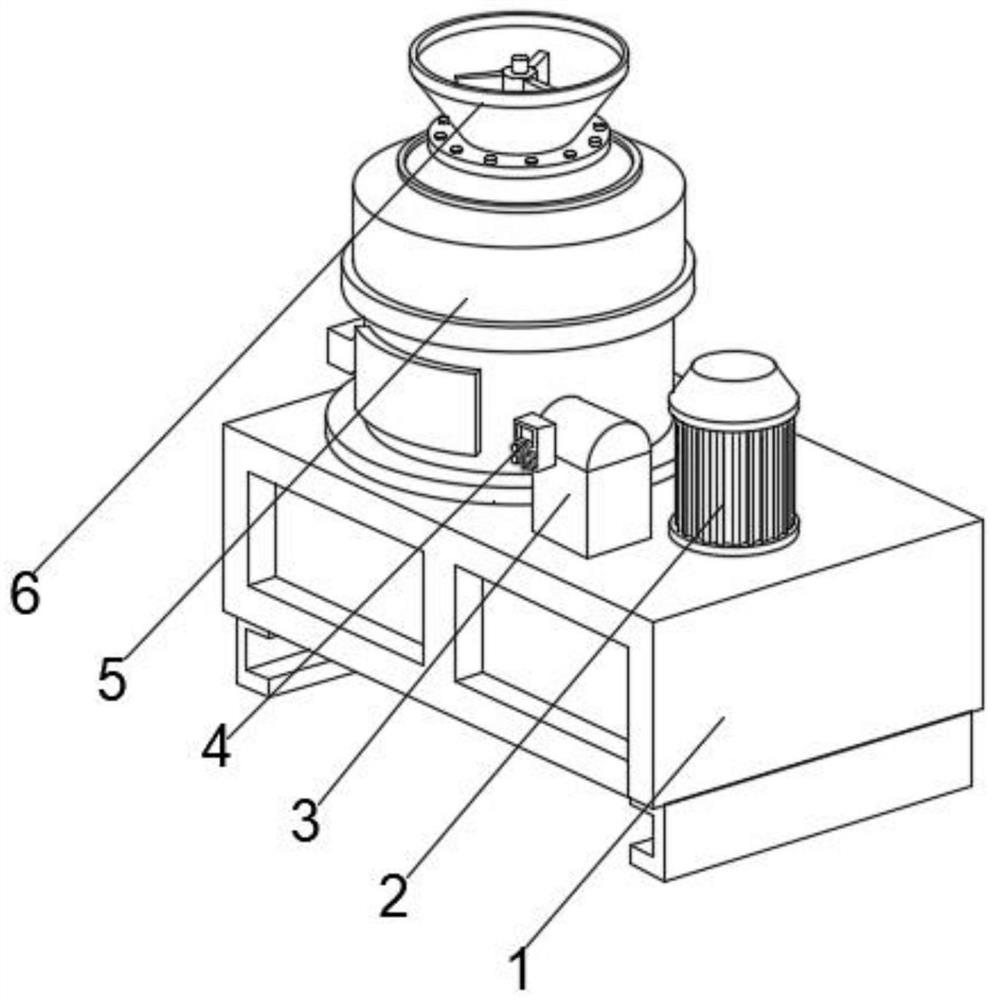

[0040] see Figure 1-6 , the present invention provides a technical solution: a preparation method of rotary granulation, which includes a main body, a driving member 2 is provided at the middle position on the top right side of the main body 1, and the output end of the driving member 2 runs through the main body 1 and extends to the bottom of the main body 1. Inside, a granulation device 5 is provided on the left side of the top of the main body 1, and a feed hopper 6 is provided at the middle of the top of the granulation device 5. A control panel 4 is fixedly connected to the top left side of the connecting body 3 .

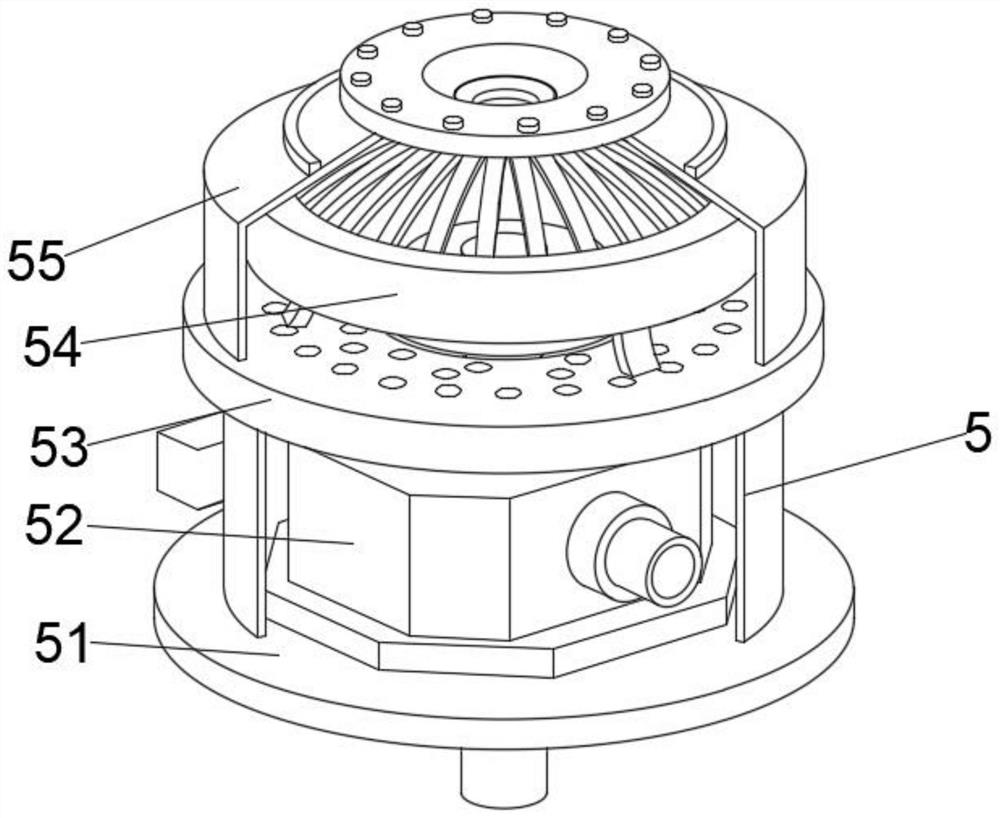

[0041] Wherein, the granulation device 5 includes a fixed frame 51, a granulation mechanism 52 is arranged at the middle position of the inner cavity bottom of the fixed frame 51, the bottom middle position of the granulation mechanism 52 runs through the fixed frame 51, and the top of the fixed frame 51 is fixedly connected with a transition plate 53 , auxi...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using rotary granulation, step 1: move and fix the equipment, connect the feed hopper 6 with the granulation device 5, and drive the Part 2 is energized, and raw materials are added inside the feed hopper 6;

[0048] Step 2: During the start-up process of the equipment, the protective shell 55 communicates with the auxiliary mechanism 54, and the raw materials that are initially stirred fall into the interior of the auxiliary mechanism, and the granulation of the granulation mechanism 52 continues to drop uniform particles;

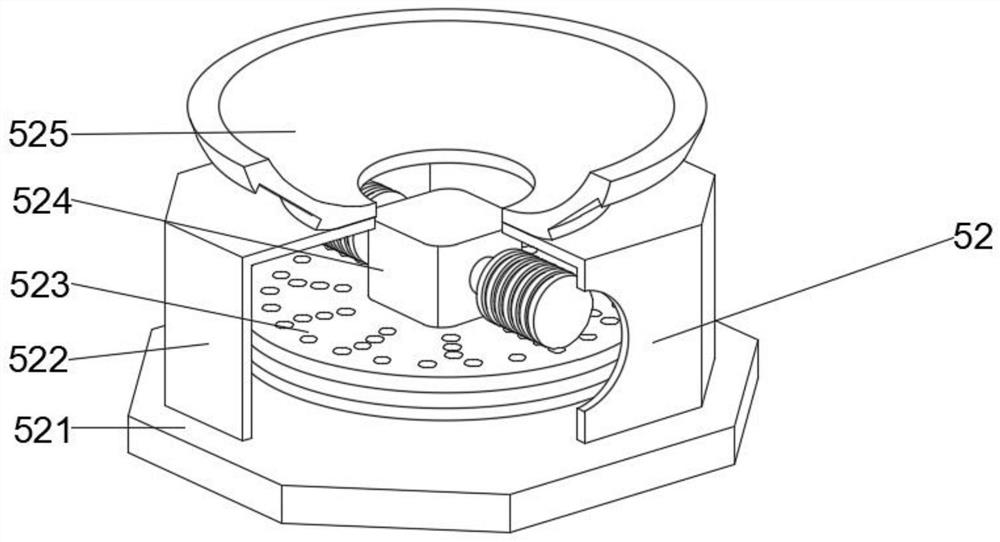

[0049] Step 3: When the power part drives the roller compactor 524 to rotate, the rotating granulation plate 523 is driven by another power part to rotate in the opposite direction with the roller compactor 524, and the sealing shell 522 is connected to the shroud 525 The falling of raw materials realizes buffer concentration;

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com