Vertical equal-eccentric-distance inertia crusher

A technology of eccentricity and crusher, which is applied in the direction of grain processing, etc., to achieve the effect of increasing equipment processing capacity, reducing manufacturing difficulty, and increasing crushing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

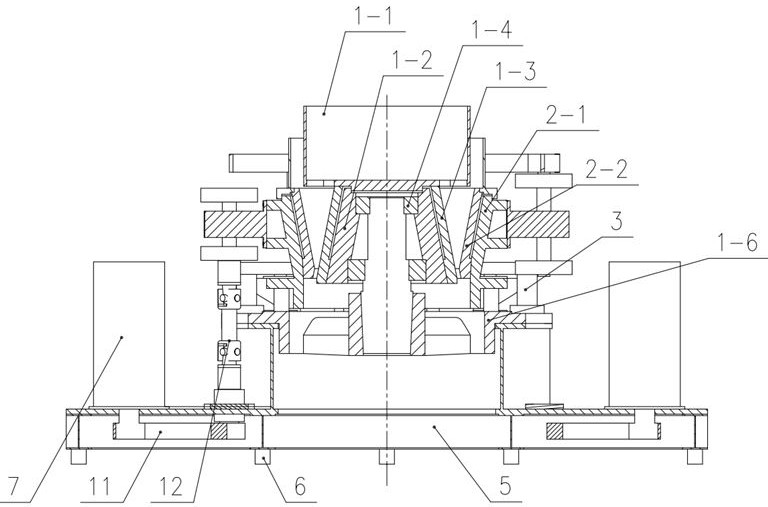

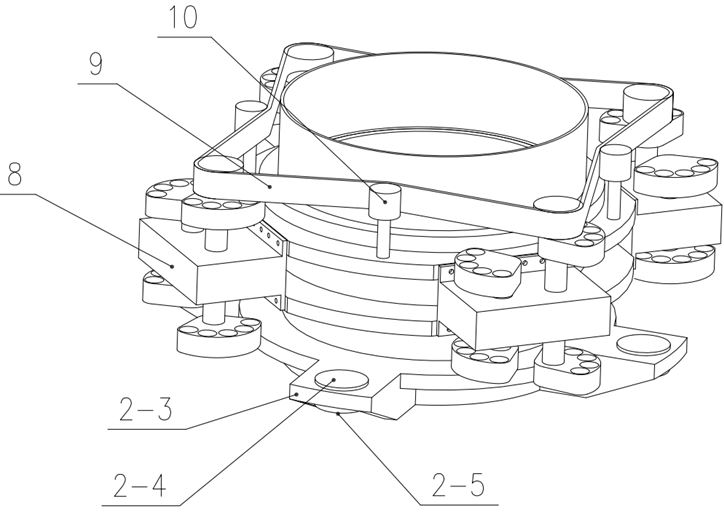

[0034] Such as Figure 1-5 As shown, specific embodiment 1: a vertical inertial crusher with equal eccentricity, which has an internal frame 1, an external frame 2, a shear spring 3, a limiting device 4, a base 5, a vibration isolation spring 6, a driving device 7, and an exciter 8. Synchronization device 9. Wherein: the inner frame 1 is composed of a feeding cylinder, an inner cone, an inner cone liner 1-3, a main shaft 1-4, a bearing 1-5 and an inner lower frame 1-6. The inner cone is fixed on the main shaft 1-4 through the bearing 1-5, the inner cone liner 1-3 is connected and fixed on the inner cone, the feeding cylinder is connected and fixed on the inner cone, the feeding cylinder, the inner cone 1. The whole formed by the inner cone liner 1-3 can rotate on the main shaft 1-4 through the bearing 1-5, and the main shaft 1-4 is connected and fixed on the inner lower frame 1-6.

[0035] The inner frame 1 is connected and fixed with the base 5, the outer frame 2 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com