A vertical equal eccentricity inertial crusher

A technology of eccentricity and crusher, which is applied in the direction of grain processing, etc., to achieve the effect of simplifying the motion state, improving the reliability of equipment operation, and increasing the crushing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

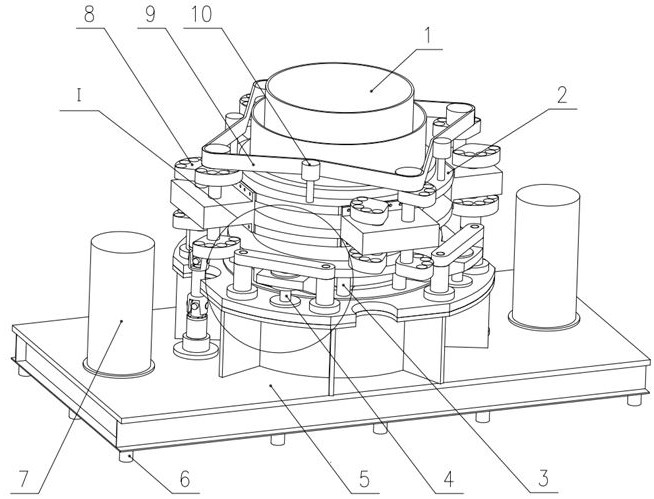

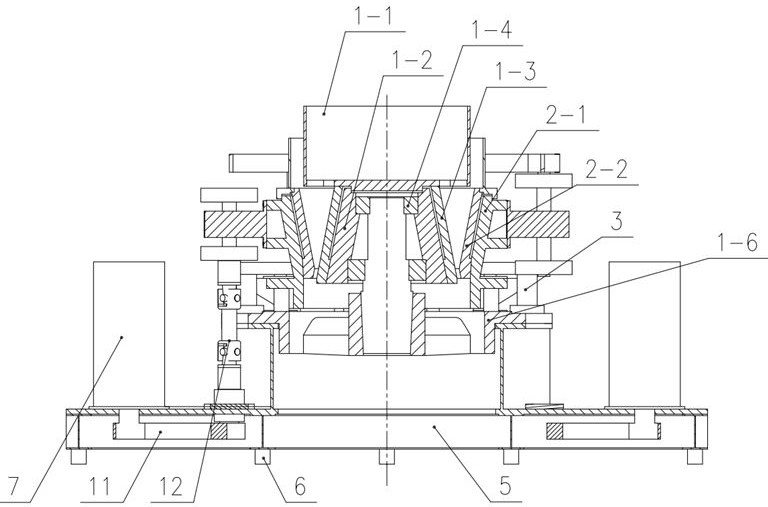

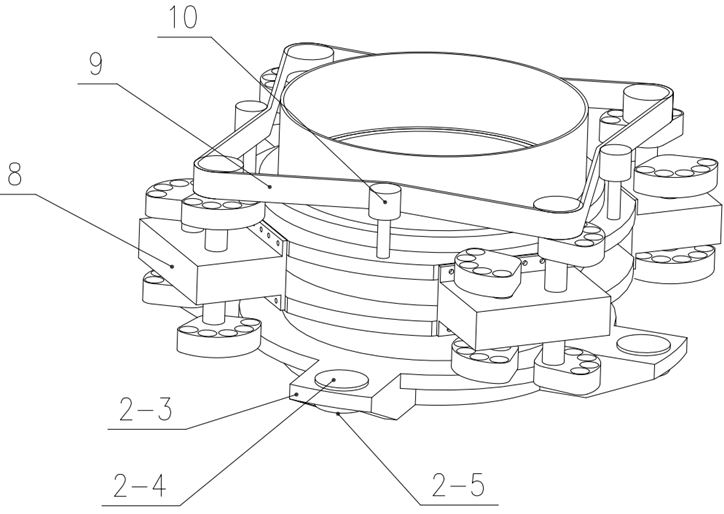

[0034] like Figure 1-5 As shown, specific embodiment 1: vertical equal eccentricity inertial crusher, with inner frame 1, outer frame 2, shear spring 3, limiting device 4, base 5, vibration isolation spring 6, driving device 7, vibration exciter 8. Synchronization device 9. Among them: the inner frame 1 is composed of a feeding cylinder, an inner cone, an inner cone lining plate 1-3, a main shaft 1-4, a bearing 1-5 and an inner lower frame 1-6. The inner cone is fixed on the main shaft 1-4 through the bearings 1-5, the inner cone lining plate 1-3 is connected and fixed on the inner cone, the feeding cylinder is connected and fixed on the inner cone, the feeding cylinder and the inner cone are connected and fixed on the inner cone. , The whole formed by the inner cone lining plate 1-3 can be rotated on the main shaft 1-4 through the bearing 1-5, and the main shaft 1-4 is connected and fixed on the inner and lower frame 1-6.

[0035] The inner frame 1 is connected and fixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com