Composite azelaic acid emulsion for preventing allergy and removing acnes and preparation method thereof

A technology of azelaic acid, sensitization and anti-acne, applied in the field of azelaic acid emulsion and its preparation, can solve the problems of patients' heavy mental burden, achieve the effect of relieving blackheads, closed mouth and acne marks, fine pores, and balance oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] To prepare 1000g of emulsion, the following materials are used:

[0036] .

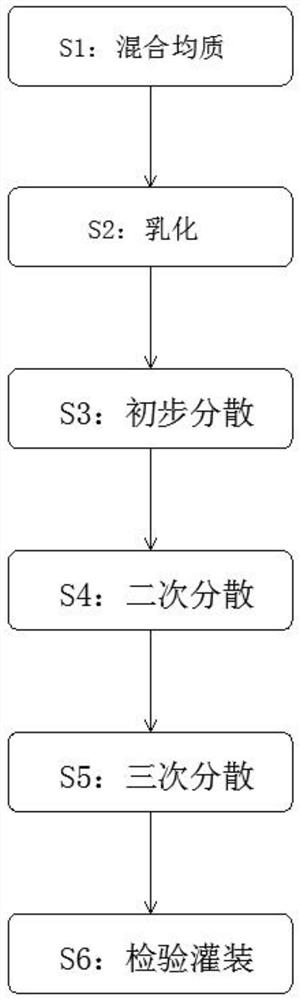

[0037] Such as figure 1 ,Preparation Process:

[0038] (1) Put 551.45g of water, 1g of disodium EDTA, 10g of steareth-21, 5g of steareth-2, and 1g of benzoic acid into the emulsification pot, heat to 70-75°C, and stir for 20-30 rpm / min, stirring for 5-10 minutes, homogenizing at 2200-2500 rpm, homogenizing for 5-10 minutes, until evenly dispersed.

[0039] (2) Keep warm at 70-75°C, add 60g of butanediol, 40g of glycerin, 10g of propylene glycol, 40g of polydimethylsiloxane, 10g of caprylic acid / capric triglyceride, 5g of hydrogenated lecithin, and 5g of wild soybean sterols Emulsification pot, homogenize at 2200-2500 rpm, homogenize for 5-10 minutes, stir at 20-30 rpm, stir for 5-10 minutes, until the emulsification is uniform.

[0040](3) Cool down to 60-65°C, add carbomer 4g into the emulsification pot, stir at 20-30 rpm, stir for 5-10 minutes, homogenize at 2200-2500 rpm, homogenize ...

Embodiment 2

[0045] To prepare 1000g of emulsion, the following materials are used:

[0046] .

[0047] Preparation Process:

[0048] (1) Put 634.49g of water, 3g of disodium EDTA, 5g of steareth-21, 1g of steareth-2, and 1g of benzoic acid into the emulsification pot, heat to 70-75°C, and stir for 20-30 rpm / min, stirring for 5-10 minutes, homogenizing at 2200-2500 rpm, homogenizing for 5-10 minutes, until evenly dispersed.

[0049] (2) Keep warm at 70-75°C, add 80g of butanediol, 30g of glycerin, 10g of propylene glycol, 50g of polydimethylsiloxane, 10g of caprylic acid / capric triglyceride, 1g of hydrogenated lecithin, and 1g of wild soybean sterols Emulsification pot, homogenize at 2200-2500 rpm, homogenize for 5-10 minutes, stir at 20-30 rpm, stir for 5-10 minutes, until the emulsification is uniform.

[0050] (3) Cool down to 60-65°C, add carbomer 4g into the emulsification pot, stir at 20-30 rpm, stir for 5-10 minutes, homogenize at 2200-2500 rpm, homogenize for 5-10 minutes, u...

Embodiment 3

[0055] To prepare 1000g of emulsion, the following materials are used:

[0056] .

[0057] Preparation Process:

[0058] (1) Put 612.93g of water, 1g of disodium EDTA, 10g of steareth-21, 10g of steareth-2, and 3g of benzoic acid into the emulsification pot, heat to 70-75°C, and stir for 20-30 rpm / min, stirring for 5-10 minutes, homogenizing at 2200-2500 rpm, homogenizing for 5-10 minutes, until evenly dispersed.

[0059] (2) Keep warm at 70-75°C, add 30g of butanediol, 20g of glycerin, 5g of propylene glycol, 10g of polydimethylsiloxane, 5g of caprylic acid / capric triglyceride, 10g of hydrogenated lecithin, and 10g of wild soybean sterols Emulsification pot, homogenize at 2200-2500 rpm, homogenize for 5-10 minutes, stir at 20-30 rpm, stir for 5-10 minutes, until the emulsification is uniform.

[0060] (3) Cool down to 60-65°C, add carbomer 1g into the emulsification pot, stir at 20-30 rpm, stir for 5-10 minutes, homogenize at 2200-2500 rpm, homogenize for 5-10 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com